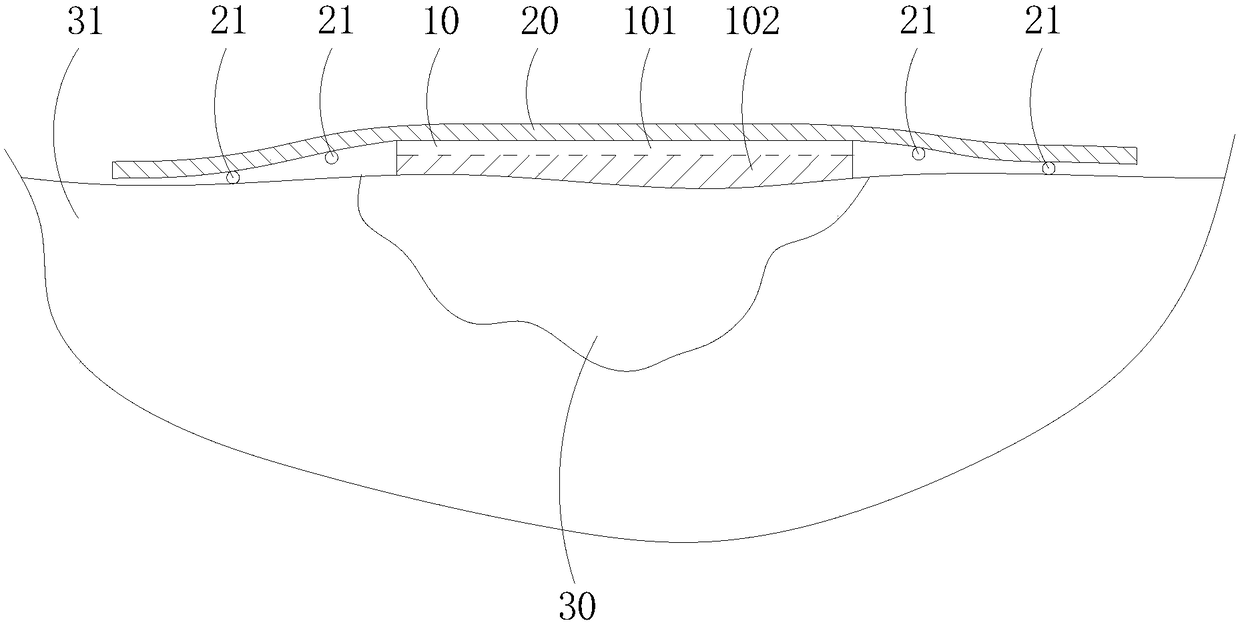

Anti-sticking dressing and manufacturing method thereof

A manufacturing method and sticking technology, applied in viscous dressings, dressings, medical science, etc., can solve the problems of no antibacterial function, wound tissue fluid is not easy to absorb, and poor moisturizing effect, so as to block external bacterial infection and excellent moisture retention , the effect of maintaining air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

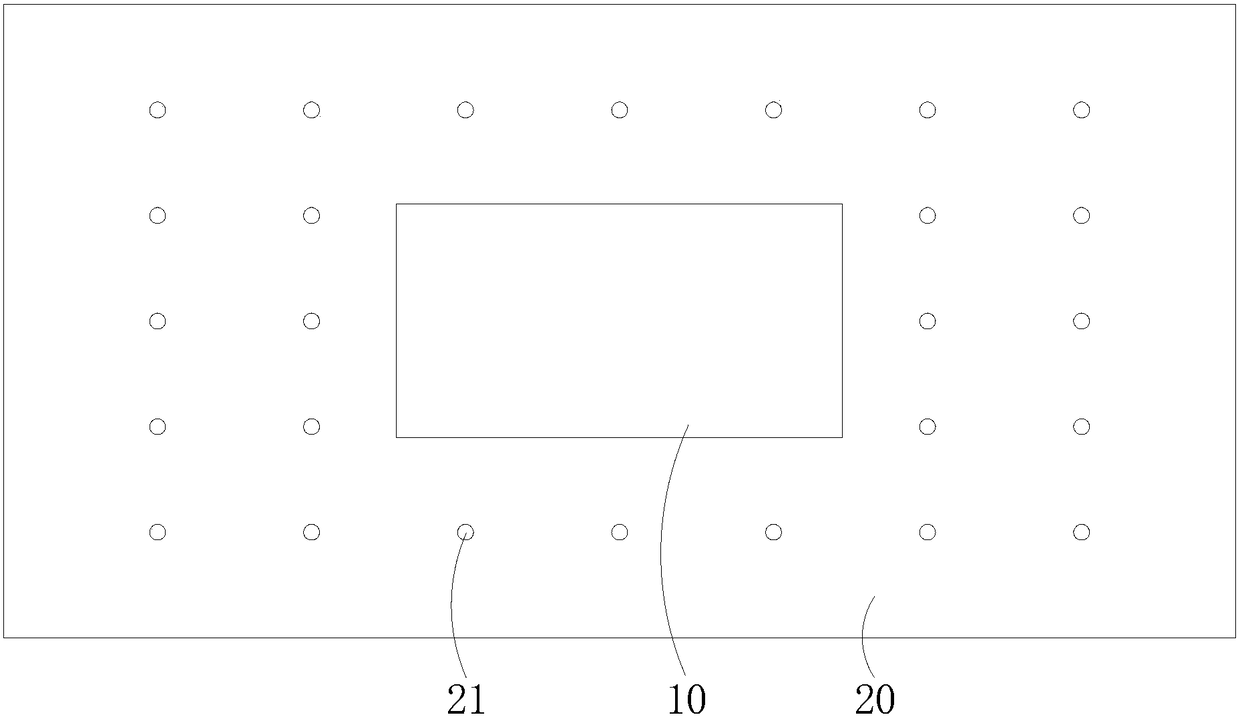

[0047] Prepare the water-based foam layer, by 2.0mol% hardener hexamethylene diisocyanate and 0.2mol% polyethylene glycol PEG2000 (polyethylene glycol, PEG, M n2000) and 0.8mol% polypropylene glycol PPG2000 (polypropylene glycol, PPG, M n 2000) mixed with 0.4mol% 2,2-dimethylol propionic acid and 0.1mol% ethylenediamine (ethylenediamine) and 0.3mol% 1,4-butanediol to form the main agent, and without adding functional additives, the preparation into a prepolymer; then use a mechanical foaming machine to make a mechanical foam, and coat it on centrifugal paper to form a water-based foam layer; a polyurethane film is formed on the water-based foam layer, and the bottom of the water-based foam layer is used for Attached to wounds of the skin; several dots of glue are coated on the polyurethane membrane.

Embodiment B

[0049] Prepare the water-based foam layer, by 2.0mol% hardener hexamethylene diisocyanate and 0.3mol% polyethylene glycol PEG2000 (polyethylene glycol, PEG, M n 2000) and 0.7mol% polypropylene glycol PPG2000 (polypropylene glycol, PPG, M n 2000) with 0.4mol% of 2,2-dimethylol propionic acid and 0.1mol% of ethylenediamine and 0.3mol% of 1,4-butanediol to form the main agent, and without adding functional additives, made Prepolymer; then use mechanical foaming machine to make mechanical foam, and spread it on centrifugal paper to make water-based foam layer; polyurethane film is formed on the water-based foam layer, and the bottom of water-based foam layer is used for pasting Attaches to wounds in the skin; the polyurethane membrane is coated with dots of glue.

Embodiment C

[0051] Prepare the water-based foam layer, first by 2.0mol% hardener hexamethylene diisocyanate and 0.4mol% polyethylene glycol PEG2000 and 0.6mol% polypropylene glycol PPG2000 and 0.4mol% 2,2-dimethylol propane The acid is mixed with 0.1mol% ethylenediamine and 0.3mol% 1,4-butanediol to form the main agent, and no functional additives are added to make a prepolymer; then mechanical foaming machine is used to make mechanical foam Foam body, coated on centrifugal paper to form a water-based foam layer; a polyurethane film is formed on the water-based foam layer, and the bottom of the water-based foam layer is used to attach to the wound of the skin; the polyurethane film is coated with a number of dots glue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com