Positioning device of high-precision laser butt welding machine

A technology of positioning device and butt welding machine, applied in laser welding equipment, auxiliary devices, welding equipment and other directions, can solve the problems of collision and bending, insufficient automation, overlapping and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

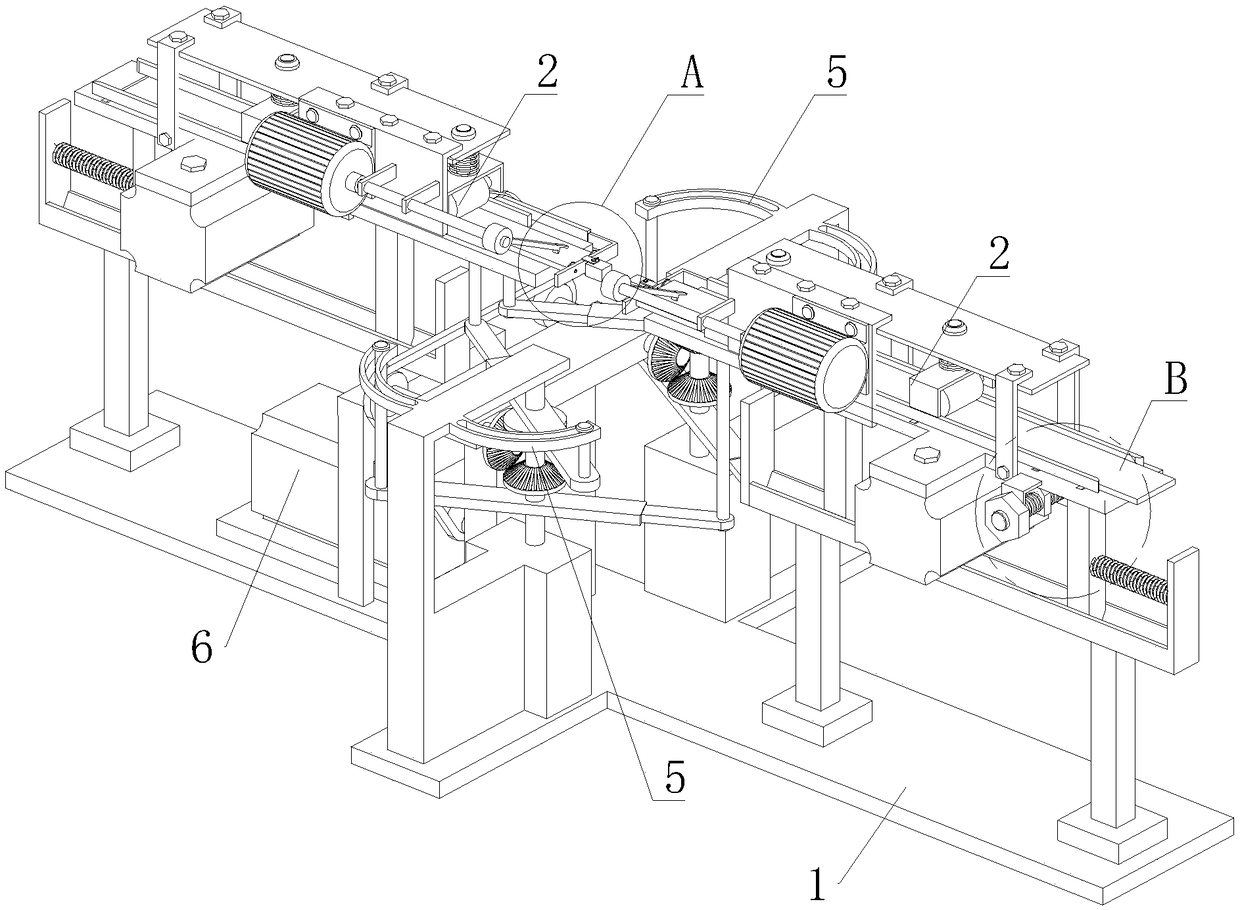

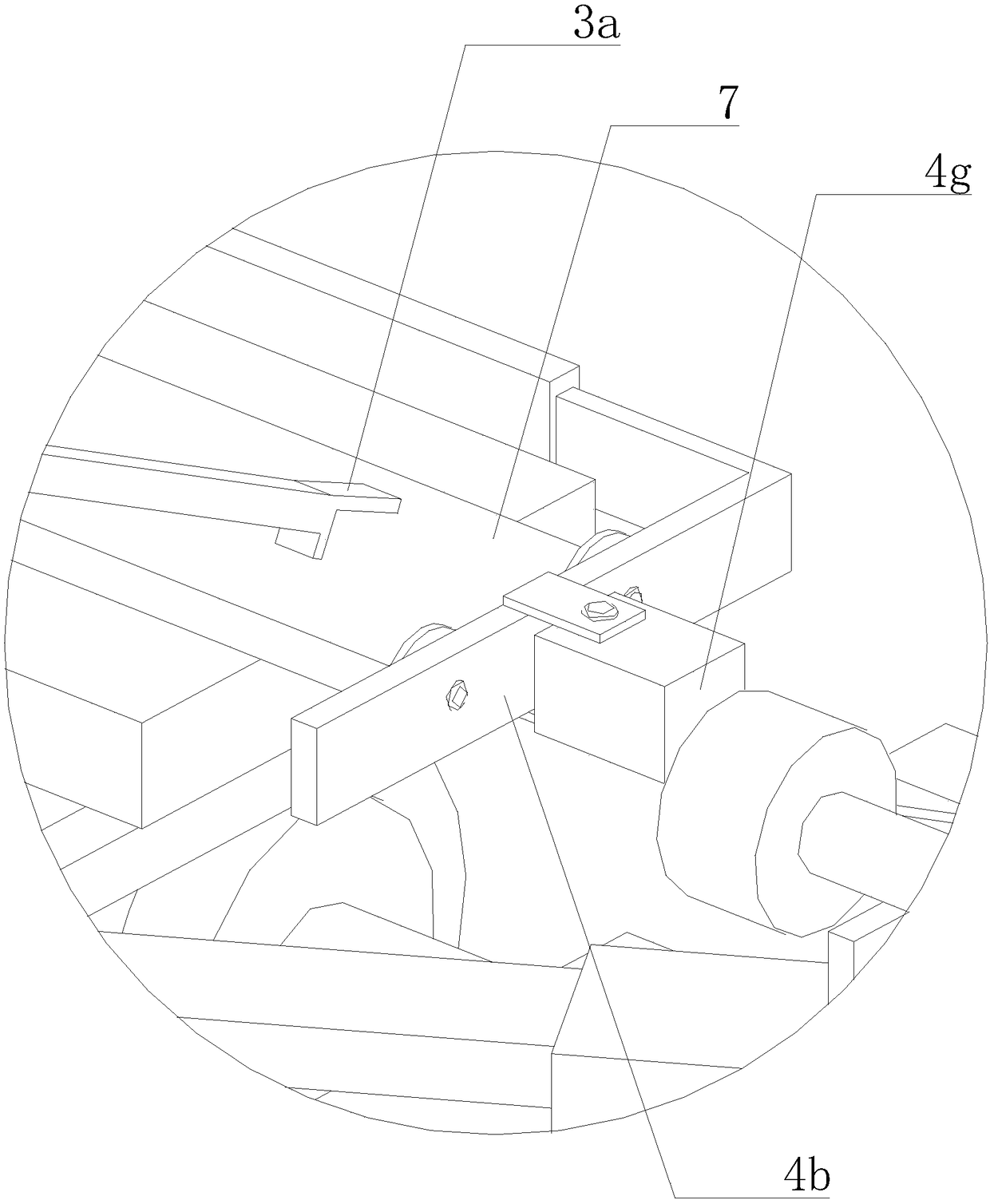

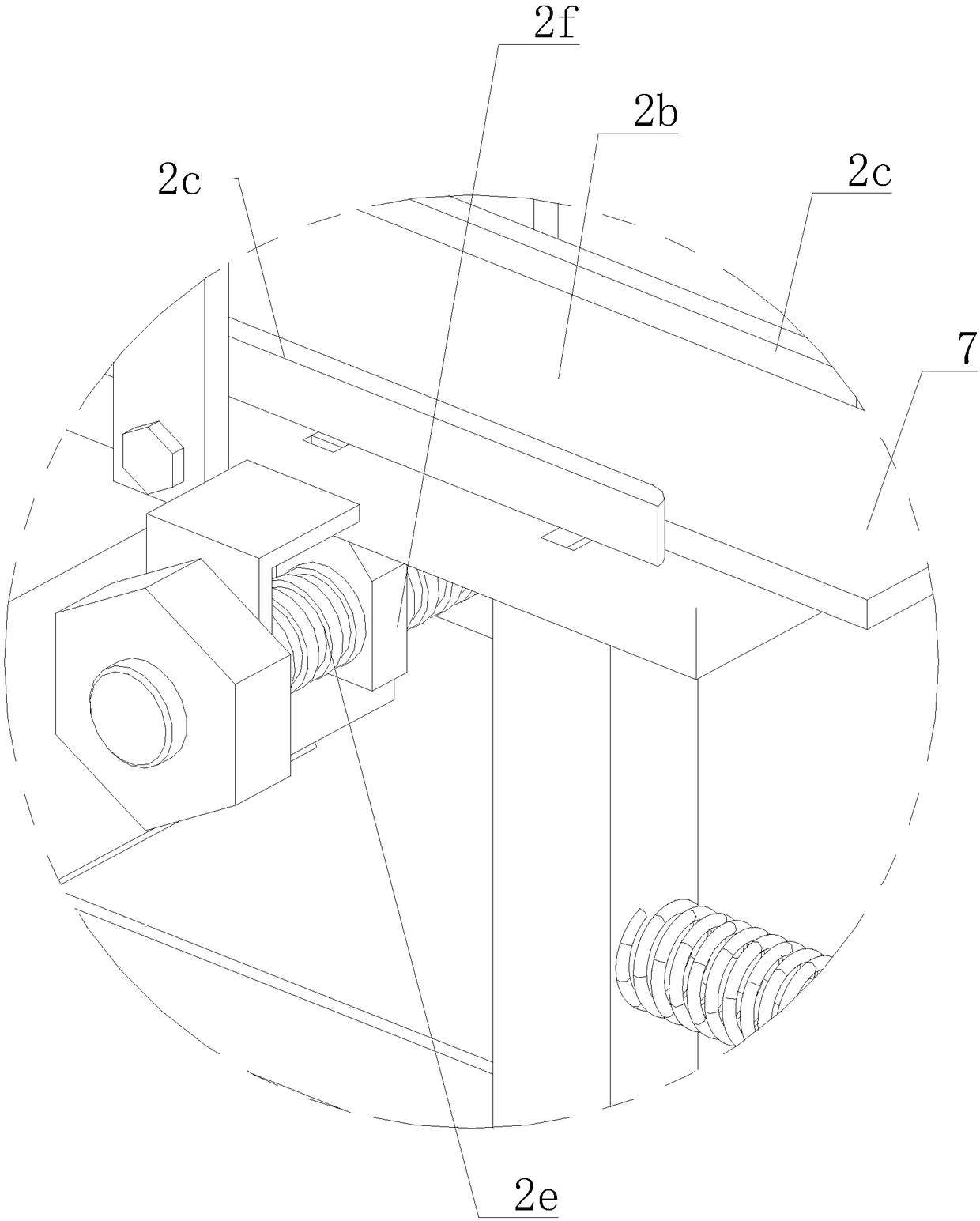

[0037] refer to Figure 1 to Figure 11 The positioning device of a high-precision laser butt welding machine shown includes a base 1, a main controller, a power mechanism 6, two docking mechanisms 5, and two positioning mechanisms 2 symmetrically arranged on the top of the base 1, and the two docking mechanisms 5 is symmetrically arranged in the middle of the two positioning mechanisms 2, and the two docking mechanisms 5 correspond to the front and rear sides of a positioning mechanism 2 respectively. The structures of the two positioning mechanisms 2 are the same, and the positioning mechanism 2 includes a guide seat 2a, a positioning fixture 2b, The blocking part 4 and the pressing part 3, the positioning fixture 2b is movably arranged above the guide seat 2a through a tension spring 2d, and the two blocking parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com