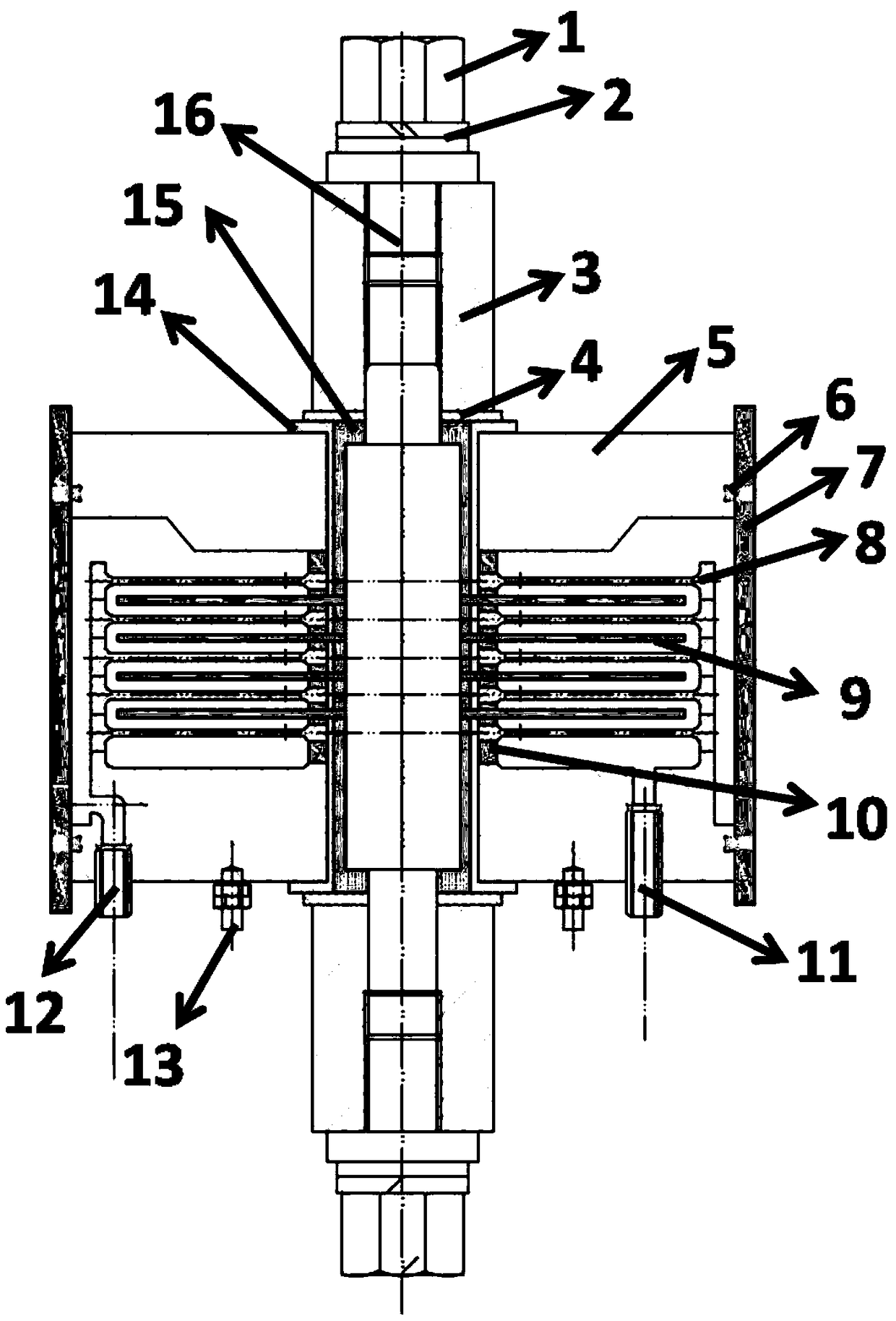

Disc-type electrocatalytic water treatment device

A water treatment device, electrocatalysis technology, applied in the direction of water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., can solve the problems of hindering wide application, unstable effect, high power consumption, etc., to achieve Increase the placement density, increase the response time, and reduce the effect of arrangement spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Ruthenium Oxide Coated Titanium Anode Disk Electrocatalytic Reactor for Treatment of Saline Industrial Wastewater:

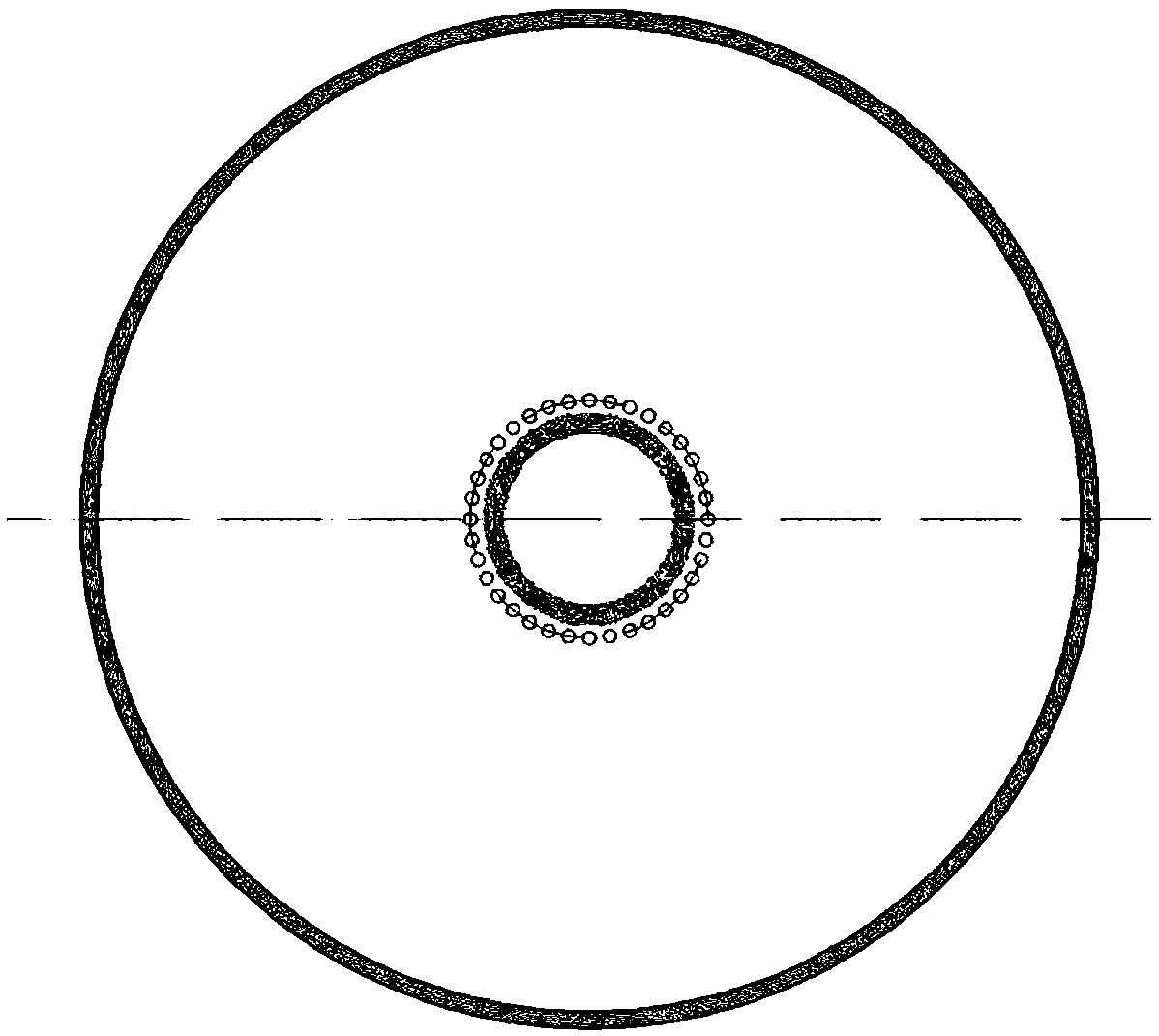

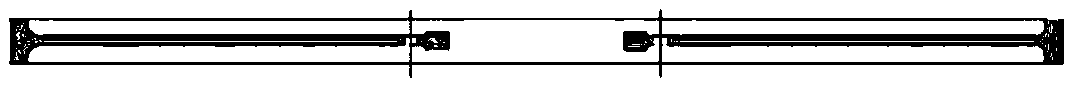

[0043] a, the cathode pressing plate 8 is a stainless steel cathode pressing plate, and the anode plate 9 is a titanium anode plate coated with ruthenium oxide;

[0044] b. Use a multi-stage centrifugal pump to pump salt-containing industrial waste water from the water inlet 12 at a flow rate of 1m / s, and the fluid passes through the channels around the central hole of the cathode pressure plate 8 to form a return flow;

[0045] c. Adjust the applied electric field voltage to 2.0V and the current density to 10mA / cm 2 ;

[0046] d. After running stably for 1 hour, take a sample from the water outlet 11, and detect the water color, ammonia nitrogen, and COD indicators.

[0047] The influent COD is 483mg / L and ammonia nitrogen is 232mg / L, which can completely remove the chroma in the water body, the effluent COD is reduced to 40mg / L, and the ammonia nitrogen...

Embodiment 2

[0049] Disc-type electrocatalytic reactor with lead oxide coated titanium anode for the treatment of saline industrial wastewater:

[0050] a. The cathode plate 8 is a stainless steel cathode plate, and the anode plate 9 is a lead oxide-coated titanium anode plate;

[0051] b. Use a multi-stage centrifugal pump to inject saline industrial waste water from the water inlet 12 at a flow rate of 2m / s, and the fluid passes through the channels around the central hole of the cathode pressure plate 8 to form a return flow;

[0052] c. Adjust the applied electric field voltage to 3.0V and the current density to 20mA / cm 2 ;

[0053] d. After running stably for 1 hour, take a sample from the water outlet 11, and detect the water color, ammonia nitrogen, and COD indicators.

[0054] The influent COD is 483mg / L and ammonia nitrogen is 232mg / L, which can completely remove the chroma in the water body, the effluent COD is reduced to 45mg / L, and the ammonia nitrogen is reduced to 1mg / L, me...

Embodiment 3

[0056] a. The cathode plate 8 is a stainless steel cathode plate, and the anode plate 9 is an antimony-tin oxide-coated titanium anode plate;

[0057] b. Use a multi-stage centrifugal pump to pump salt-containing industrial waste water from the water inlet 12 at a flow rate of 3m / s, and the fluid passes through the channels around the central hole of the cathode pressure plate 8 to form a return flow;

[0058] c. Adjust the applied electric field voltage to 4.0V and the current density to 30mA / cm 2 ;

[0059] d. After running stably for 1 hour, take a sample from the water outlet 11, and detect the water color, ammonia nitrogen, and COD indicators.

[0060] The influent COD is 483mg / L and ammonia nitrogen is 232mg / L, which can completely remove the chroma in the water body, the effluent COD is reduced to 42mg / L, and the ammonia nitrogen is reduced to 1.2mg / L, meeting the first-class standard for comprehensive sewage discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com