Flue gas atomization evaporation process and system for high-salt wastewater based on ash waste-heat recovery

A high-salt wastewater and waste heat recovery technology, applied in water/sewage treatment, water treatment parameter control, chemical instruments and methods, etc., can solve the problems of small range of use conditions, waste of high-level heat energy, high investment and operating costs, and achieve relaxation Conditions of use, reduction of disposal costs, effects of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

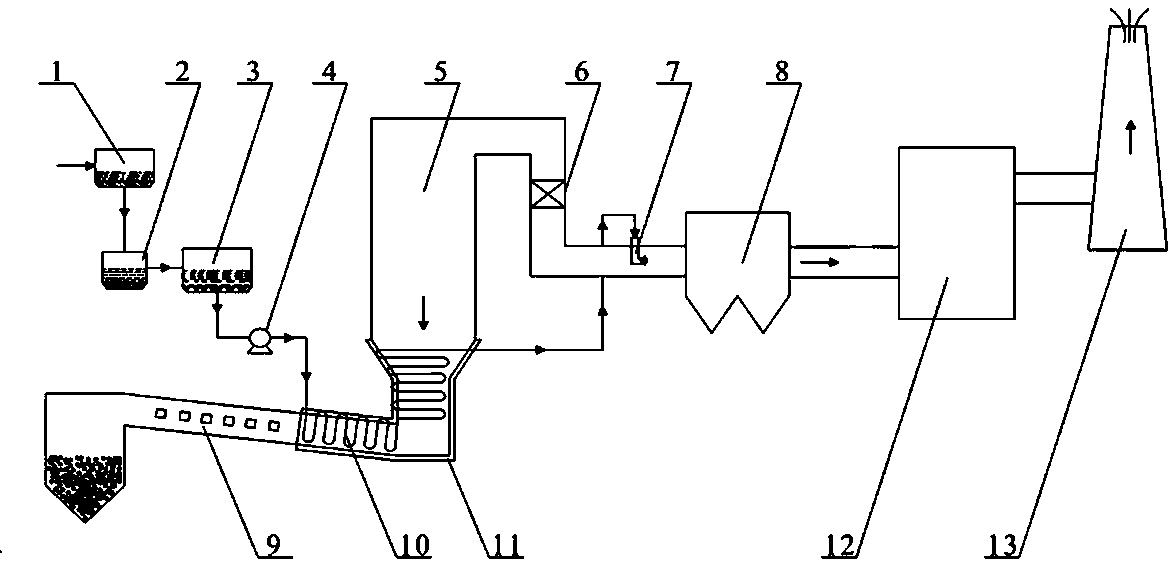

[0024] Attached below figure 1 The present invention will be further described in detail through examples, the following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0025] The high-salt wastewater flue gas atomization evaporation process based on ash waste heat recovery, the specific steps are as follows:

[0026] 1) Treat the high-salt wastewater through the depth filter device 1 so that the suspended solids content is less than 70 mg / L;

[0027] 2) Use the pH adjustment device 2 to further treat the effluent from the depth filtration device 1 to make the pH value 7-9;

[0028] 3) Using the softening device 3 to soften the outlet water of the pH adjusting device 2;

[0029] 4) Lead the effluent from the softening device 3 into the return-type heating tube 10 located at the front section of the air-cooled mechanical slag removal device 9 and the bottom of the boiler 5 through the waste water deliver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com