A kind of epoxy structural adhesive curing agent and its preparation method and application

A technology of epoxy structural adhesive and curing agent, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems that the strength, water resistance and other properties cannot be effectively guaranteed, and achieve excellent tensile strength and amine value Low, not easy to change color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

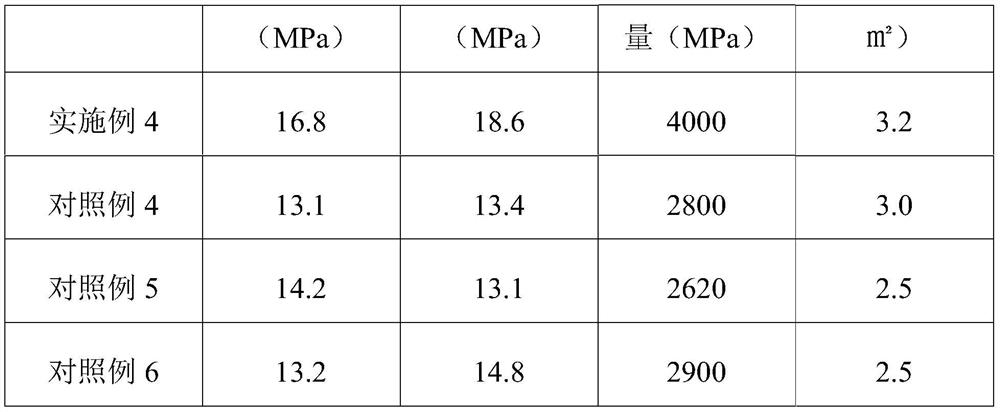

Examples

Embodiment 1

[0038] 1. Epoxy structural adhesive curing agent

[0039] The above-mentioned epoxy structural adhesive curing agent is prepared from the following raw materials in parts by weight:

[0040] 20 parts of E51 type epoxy resin, 10 parts of 692 epoxy resin reactive diluent, 20 parts of isophorone diamine, 20 parts of diethylene triamine, 30 parts of benzyl alcohol.

[0041] 2. Preparation method

[0042] The preparation method of above-mentioned epoxy structural adhesive curing agent, this preparation method comprises the steps:

[0043] (1) E51 type epoxy resin and 692 epoxy resin reactive diluent are mixed uniformly to obtain a mixture, and the mixture is equally divided into 3 parts;

[0044] (2) Isophoronediamine and diethylenetriamine are mixed and poured into the reactor;

[0045] (3) Benzyl alcohol is placed in the reactor and starts to stir;

[0046] (4) 3 points of the mixture in step (1) are placed in the reaction kettle at intervals for reaction, wherein the interva...

Embodiment 2

[0050] 1. Epoxy structural adhesive curing agent

[0051] The above-mentioned epoxy structural adhesive curing agent is prepared from the following raw materials in parts by weight:

[0052] 10 parts of E51 type epoxy resin, 5 parts of 692 epoxy resin reactive diluent, 20 parts of isophorone diamine, 10 parts of diethylene triamine, 40 parts of benzyl alcohol.

[0053] 2. Preparation method

[0054] The preparation method of above-mentioned epoxy structural adhesive curing agent, this preparation method comprises the steps:

[0055] (1) E51 type epoxy resin and 692 epoxy resin reactive diluent are mixed uniformly to obtain a mixture, and the mixture is equally divided into 3 parts;

[0056] (2) Isophoronediamine and diethylenetriamine are mixed and poured into the reactor;

[0057] (3) Benzyl alcohol is placed in the reactor and starts to stir;

[0058] (4) 3 points of the mixture in step (1) are placed in the reaction kettle at intervals for reaction, wherein the interval...

Embodiment 3

[0062] 1. Epoxy structural adhesive curing agent

[0063] The above-mentioned epoxy structural adhesive curing agent is prepared from the following raw materials in parts by weight:

[0064] 19 parts of E51 type epoxy resin, 10 parts of 692 epoxy resin reactive diluent, 21 parts of isophorone diamine, 15 parts of diethylene triamine, 35 parts of benzyl alcohol.

[0065] 2. Preparation method

[0066] The preparation method of above-mentioned epoxy structural adhesive curing agent, this preparation method comprises the steps:

[0067] (1) E51 type epoxy resin and 692 epoxy resin reactive diluent are mixed uniformly to obtain a mixture, and the mixture is equally divided into 3 parts;

[0068] (2) Isophoronediamine and diethylenetriamine are mixed and poured into the reactor;

[0069] (3) Benzyl alcohol is placed in the reactor and starts to stir;

[0070] (4) 3 points of the mixture in step (1) are placed in the reaction kettle at intervals for reaction, wherein the interva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com