Compression end point temperature adjusting method for fast compressor in lab

A technology of end point temperature and adjustment method, which is applied in the simulation of internal combustion engine compression stroke and in the field of combustion, can solve the problems of increasing the volume of the combustion chamber, limitation, and difficulty in achieving a high pressure of the mixed gas, so as to save time, reduce initial pressure, eliminate wear and tear. The effect of changes in the experimental initial conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention will be further described below in conjunction with the accompanying drawings and embodiments.

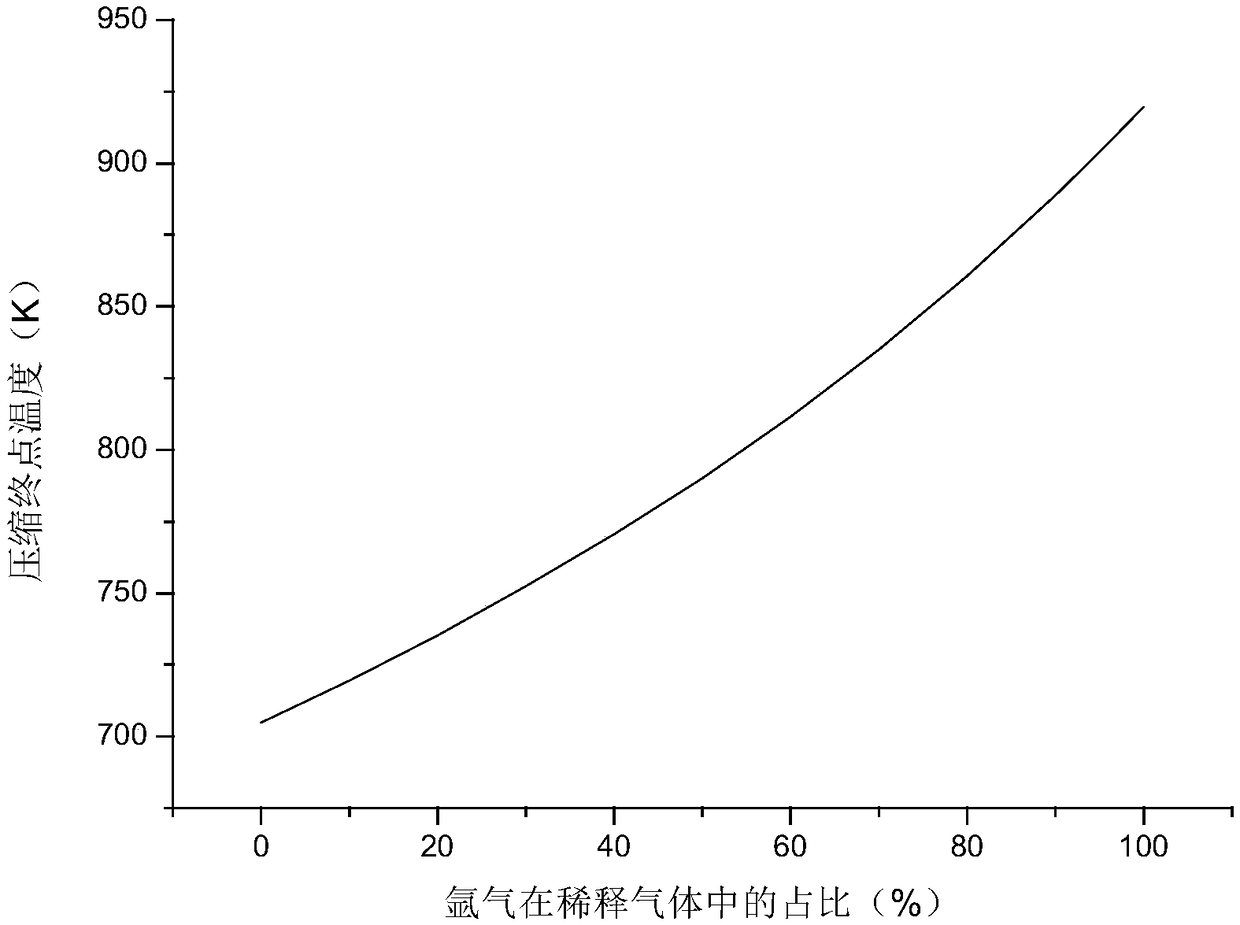

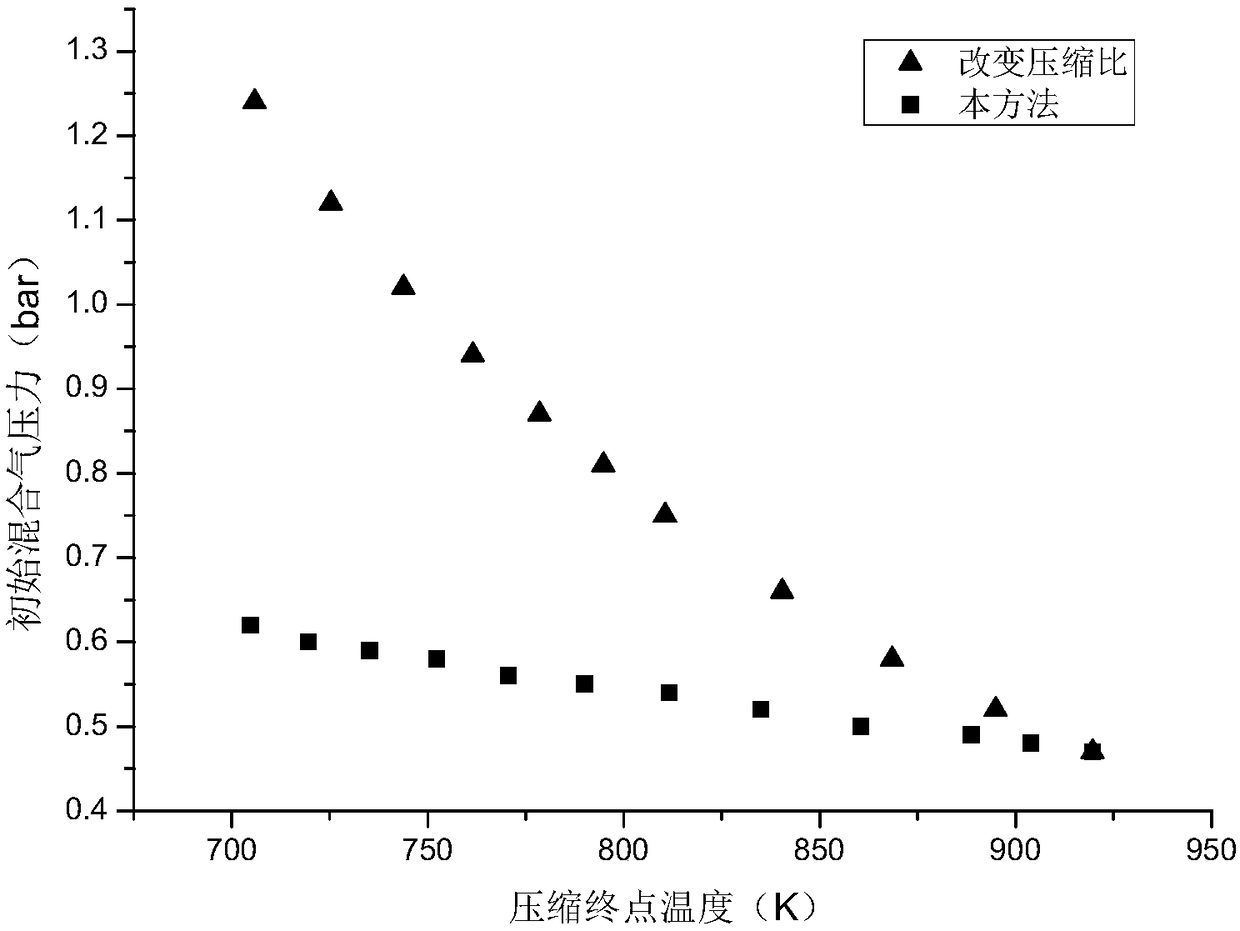

[0030] For different research objects and experimental conditions, the improvement effect of this method is not the same. The following is illustrated in conjunction with specific examples. For a combustible mixture composed of n-heptane, oxygen, and diluent gas, under the conditions of equivalence ratio 1.0, dilution ratio 3.72, and compression end pressure of 20 bar, it is desired to adjust the compression end temperature of the combustible mixture from 850K to 750K.

[0031] 1) The specific heat capacity ratios of n-heptane, oxygen, argon, and nitrogen are found to be γ1, γ2, γ3, and γ4 in the material thermodynamic parameter manual.

[0032] 2) According to the equivalence ratio and the dilution ratio, determine the volume ratios of n-heptane, oxygen, and diluent gas in the total combustible mixture as X1, X2, and Xd, respectively. There is X1+X2+Xd=1.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com