A detection method for iron ore powder assimilation reaction temperature and assimilation reaction speed

A technology of reaction speed and reaction temperature, applied in the direction of measuring devices, instruments, investigation stages/state changes, etc., can solve the problems of inability to accurately detect the minimum assimilation temperature of iron ore powder and assimilation reaction speed, so as to improve objectivity and accuracy performance, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

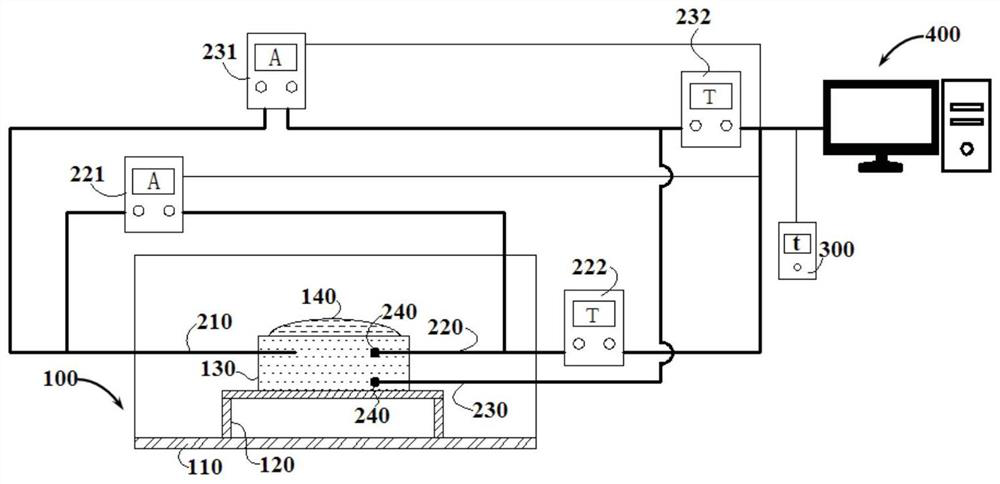

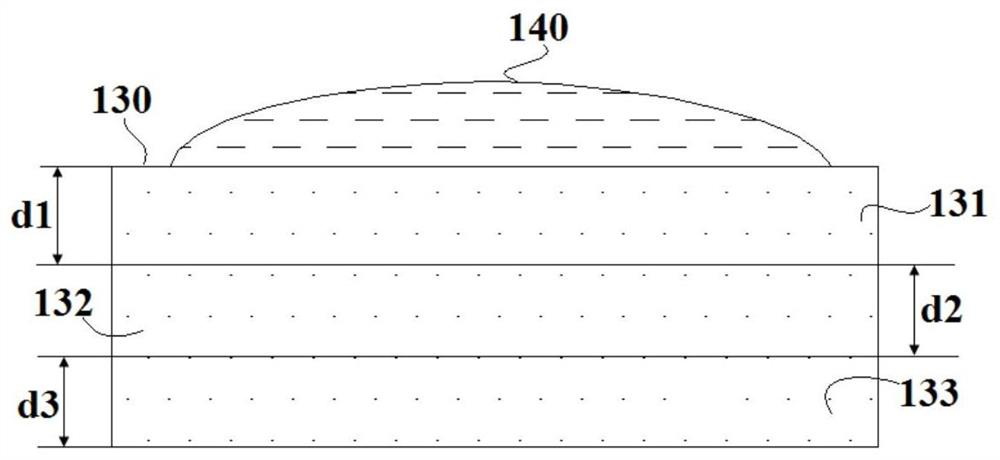

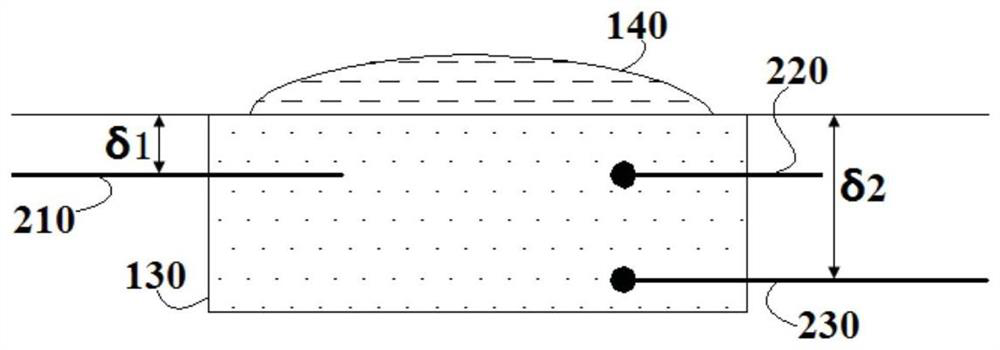

[0044] combine Figure 12 As shown, the detection method of a kind of iron ore powder assimilation reaction temperature and assimilation reaction speed of the present invention utilizes the detection device that is provided with electrode to detect the electric signal and temperature in the assimilation reaction process of iron ore powder sample 140 in the heating process. In the case of time change, the assimilation temperature and the time t required for the reaction process are judged by the change of the electrical signal, and then the assimilation reaction rate is calculated by using the time t and the distance δ between the electrodes. The specific process is as follows: first prepare the sample, cover the iron ore powder sample 140 on the calcium oxide tablet 130 of the detection device, and set the electrodes inside the calcium oxide tablet 130; The first detection unit and the second detection unit detect the electrical signal and temperature change over time during t...

Embodiment 2

[0089] combine Figure 5-11 As shown, the content of this embodiment is basically the same as that of Embodiment 1, and the difference is that a device for detecting iron ore powder assimilation temperature and assimilation reaction speed of this embodiment also includes a reaction timer 310, and the reaction timer 310 is connected with the assimilation reaction speed. The control processing unit 400 is electrically connected, and the reaction timer 310 times the reaction process, so that the time taken for the iron ore powder sample 140 and the calcium oxide tablet 130 to react to the third electrode 230 can be known, and further by calculating the time between the electrodes. The ratio of the distance between them and the time taken for the reaction gives the assimilative reaction rate. In the process of detecting the assimilation reaction in this implementation, when the temperature measurement part a222 detects that the temperature rises to 1150 ° C, the timer 300, the det...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com