A temperature prediction method of electric power equipment based on depth neural network

A deep neural network and power equipment technology, applied in the field of power equipment fault monitoring, can solve problems such as not considering the influence of equipment surface temperature, heavy and complicated workload, and affecting equipment temperature, so as to achieve unattended mode and improve convenience , the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

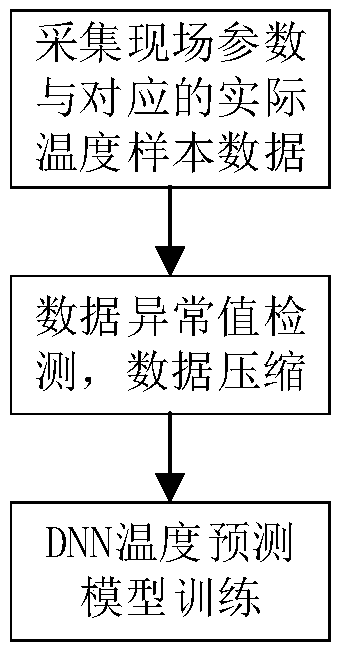

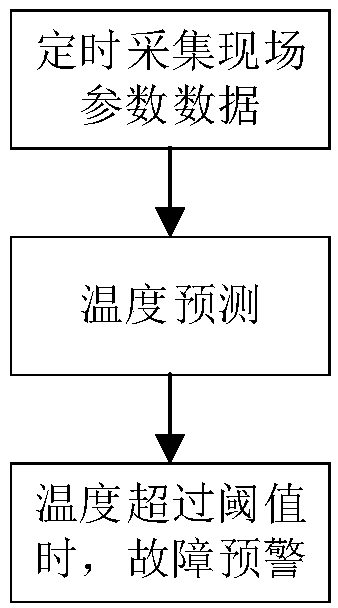

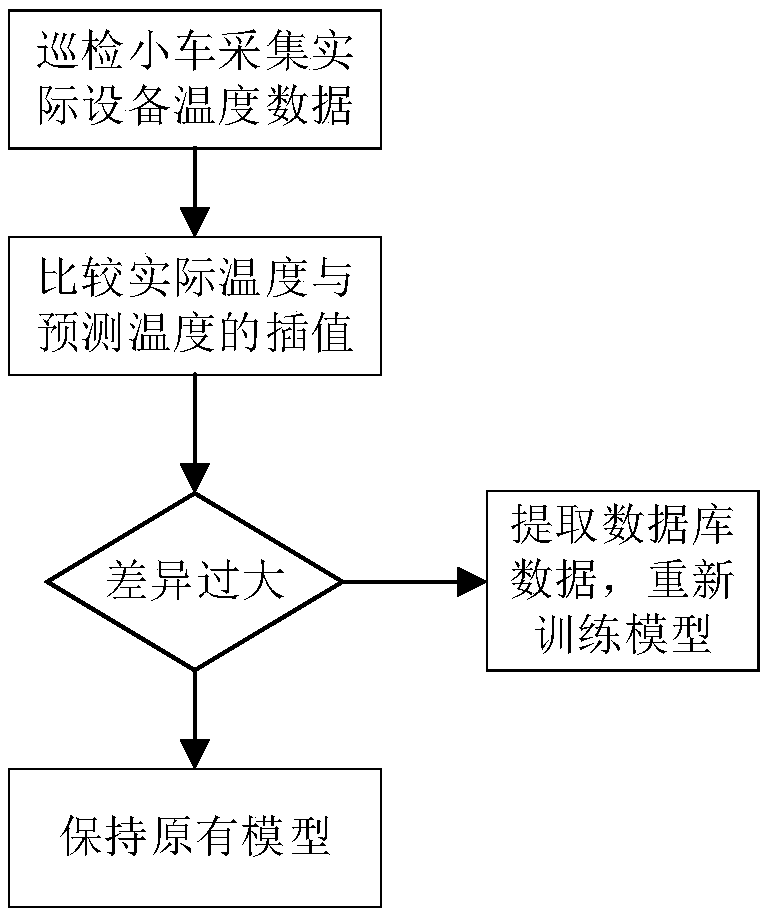

[0084] combine figure 1 , the present invention is based on the power equipment temperature prediction method of deep neural network, comprises the following steps:

[0085] Step 1. Collect the sample data of on-site parameters and the corresponding actual equipment temperature data after 30 minutes, transmit them to the background monitoring system, then preprocess the data, and train the temperature prediction model through the deep neural network; figure 1 As shown, the specific steps are:

[0086] Step 1-1. Collect sample data of on-site parameters: Obtain sample data of on-site parameters through the on-site environmental detector and load forecast, including ambient temperature, sunshine intensity, wind speed, ambient humidity, and load size; collect each set of on-site parameters after 30 minutes The actual device temperature data corresponding to the sample data;

[0087] Step 1-2, data preprocessing: perform outlier detection and elimination based on neighborhood de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com