Nitrogen desorption and recovery process for organic waste gas

An organic waste gas and organic gas technology, which is applied in gas treatment, dispersed particle filtration, membrane technology and other directions, can solve the problems of acidic exhaust gas, affect reuse, and high solvent moisture content, and achieve high recovery efficiency, cost savings, and purity. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

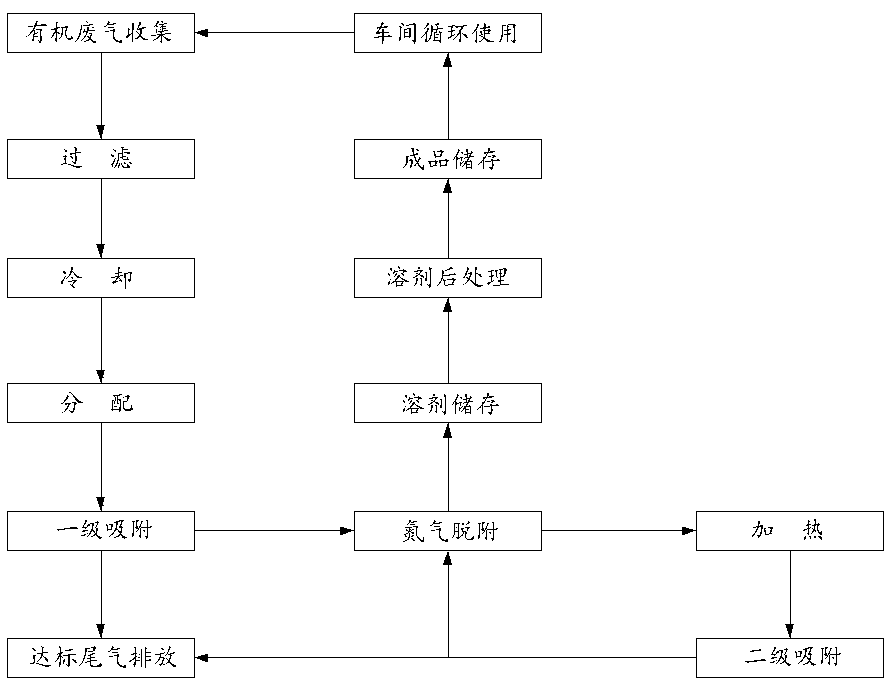

Image

Examples

Embodiment 1

[0026] A nitrogen desorption recovery process for organic waste gas, characterized in that it comprises the following steps:

[0027] (1) Organic waste gas collection: collect organic waste gas in the workshop through waste gas collection equipment;

[0028] (2) Filtration: The collected exhaust gas is discharged into the filter through a high-pressure fan for filtration, and the solid particle impurities are removed;

[0029] (3) Cooling: discharge the filtered organic waste gas into the cooling tower for cooling treatment;

[0030] (4) Distribution: Evenly distribute the cooled organic waste gas to several primary adsorption tanks through the air collector distributor;

[0031] (5) Primary adsorption: Adsorption treatment of organic waste gas is carried out through several primary adsorption tanks;

[0032] (6) Nitrogen desorption: use nitrogen to desorb organic waste gas;

[0033] (7) Solvent storage: the desorbed organic gas is cooled and liquefied and then stored as a ...

Embodiment 2

[0044] A nitrogen desorption recovery process for organic waste gas, characterized in that it comprises the following steps:

[0045] (1) Organic waste gas collection: collect organic waste gas in the workshop through waste gas collection equipment;

[0046] (2) Filtration: The collected exhaust gas is discharged into the filter through a high-pressure fan for filtration, and the solid particle impurities are removed;

[0047] (3) Cooling: discharge the filtered organic waste gas into the cooling tower for cooling treatment;

[0048] (4) Distribution: Evenly distribute the cooled organic waste gas to several primary adsorption tanks through the air collector distributor;

[0049] (5) Primary adsorption: Adsorption treatment of organic waste gas is carried out through several primary adsorption tanks;

[0050] (6) Nitrogen desorption: use nitrogen to desorb organic waste gas;

[0051] (7) Solvent storage: the desorbed organic gas is cooled and liquefied and then stored as a ...

Embodiment 3

[0062] A nitrogen desorption recovery process for organic waste gas, characterized in that it comprises the following steps:

[0063] (1) Organic waste gas collection: collect organic waste gas in the workshop through waste gas collection equipment;

[0064] (2) Filtration: The collected exhaust gas is discharged into the filter through a high-pressure fan for filtration, and the solid particle impurities are removed;

[0065] (3) Cooling: discharge the filtered organic waste gas into the cooling tower for cooling treatment;

[0066] (4) Distribution: Evenly distribute the cooled organic waste gas to several primary adsorption tanks through the air collector distributor;

[0067] (5) Primary adsorption: Adsorption treatment of organic waste gas is carried out through several primary adsorption tanks;

[0068] (6) Nitrogen desorption: use nitrogen to desorb organic waste gas;

[0069] (7) Solvent storage: the desorbed organic gas is cooled and liquefied and then stored as a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com