Precious-metal-free formaldehyde-eliminating supported catalyst and preparation method thereof

A supported catalyst and formaldehyde elimination technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problem of high preparation cost, and achieve the effect of simple preparation process, reasonable design and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of the above-mentioned catalyst is as follows: take a certain weight of activated carbon, adopt an equal-weight impregnation method, and measure deionized water according to the water capacity of the activated carbon; weigh compound A and inorganic ammonium B to add a good amount of deionized water, and stir until After fully dissolving, prepare the impregnating liquid; pour the prepared impregnating liquid evenly on the activated carbon carrier, and keep stirring. After fully impregnating, put the mixture into a sealed bag, let it stand for 1~4 hours, and then bake it at a certain temperature Drying, the drying temperature is 40℃~160℃.

[0019] The catalyst uses activated carbon as a carrier material. The carrier material is a porous adsorption material with a large specific surface area and a reasonable pore structure distribution, including but not limited to activated carbon. Activated carbon can be replaced by other porous adsorption materials...

Embodiment 1

[0022] Take 100g of coal-based (diameter 20mm) columnar activated carbon, measure a certain weight of deionized water according to the water capacity of the activated carbon, choose 2-imidazolidinone for compound A, choose ammonium sulfate for inorganic ammonium B, and take 8g of 2-imidazolidinone , take 5g of ammonium sulfate (that is, the addition ratio between 2-imidazolidinone and ammonium sulfate is 8:5) into a good amount of deionized water, stir until fully dissolved, pour the prepared impregnation solution on the activated carbon, and Stir constantly, wait until fully impregnated, place for 2 hours and then dry at 120°C.

Embodiment 2

[0024] Take 100g of coal-based (diameter 20mm) columnar activated carbon, take a certain weight of deionized water according to the water capacity of the activated carbon, choose 2-imidazolidinone for amine compound A, and choose ammonium sulfate for inorganic ammonium B, where 2-imidazolidinone Take 15g, take 6.43g of ammonium sulfate (that is, the addition ratio between 2-imidazolidinone and ammonium sulfate is 7:3), add it to a good amount of deionized water, stir until it is fully dissolved, and pour the prepared impregnation solution on the activated carbon and keep stirring until fully impregnated, place for 2 hours and then dry at 120°C.

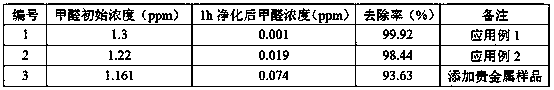

[0025] Catalyst prepared by the present invention sees the following table 1 to the elimination effect of formaldehyde:

[0026] Table 1 Catalyst to the elimination effect of formaldehyde

[0027]

[0028] It can be seen from the table that the catalysts prepared in the examples of the present invention have good protection and el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com