Controllable bidirectional three-dimensional deformed hydrogel film, preparation method thereof and flexible microelectrode array

A three-dimensional deformation and hydrogel technology, applied in the field of hydrogel, can solve the problems of complex structure and inability to control the deformation degree of hydrogel materials, and achieve the effect of controllable adjustment of deformation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

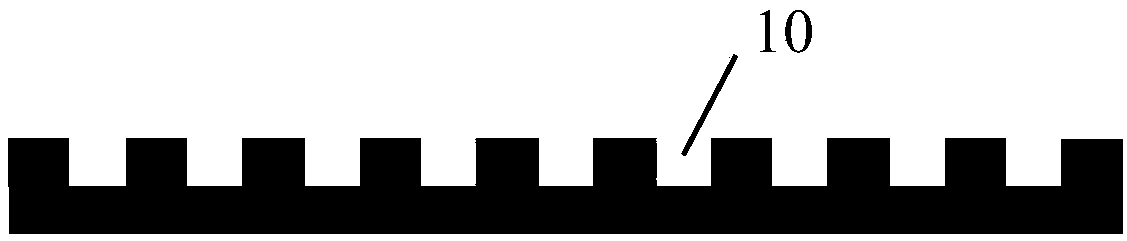

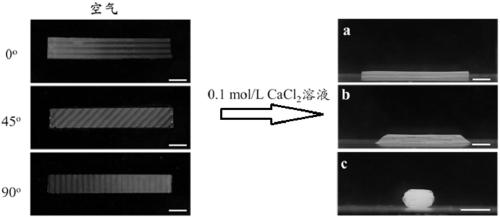

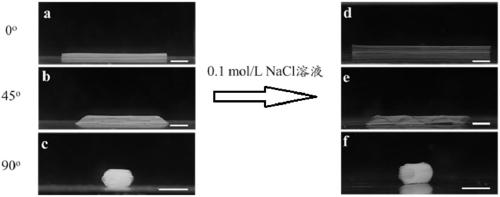

[0054] A controllable two-way three-dimensional deformable hydrogel film, the surface of the hydrogel film has oriented microchannels and a gradient of crosslinking degree on the thickness, and the hydrogel film is obtained by crosslinking sodium alginate with calcium ions ; Wherein, the depth of the microchannel is 100 μm, and the width is 800 μm.

[0055] The preparation method of the controllable bidirectional three-dimensional deformation hydrogel film comprises the following steps:

[0056] (1) Clean the silicon wafer with acetone, ethanol, and water in sequence, purge it with nitrogen gas, and place it in a plasma cleaning machine for 1 min. The photoresist SU-8 3050 was spin-coated onto the surface of the silicon wafer at a speed of 1200r / min for 30s, and then placed on a hot stage at 95°C for 30s. Finally, a silicon-based template (with a length and width of 4 cm×4 cm) with a specific structure was obtained after photolithography (using a photolithography machine mode...

Embodiment 2

[0062] A controllable two-way three-dimensional deformable hydrogel film, the surface of the hydrogel film has microchannels arranged in an orientation and a gradient of crosslinking degree on the thickness, and the material of the hydrogel film is sodium alginate crosslinked with zinc ions. The microchannels are obtained in a joint; the depth of the microchannel is 5 μm, and the width is 1 μm.

[0063] The preparation method of the controllable bidirectional three-dimensional deformation hydrogel film comprises the following steps:

[0064] (1) Clean the silicon wafer with acetone, ethanol, and water in sequence, purge it with nitrogen gas, and place it in a plasma cleaning machine for 1 min. The photoresist AZ 5214 was spin-coated onto the surface of the silicon wafer at a speed of 3000r / m for 30s, and then placed on a hot stage at 95°C for 30s. Finally, a silicon-based template (with a length and width of 4 cm×4 cm) with a specific structure was obtained after photolithogr...

Embodiment 3

[0070] A controllable two-way three-dimensional deformable hydrogel film, the surface of the hydrogel film has microchannels arranged in an orientation and a cross-linking degree gradient on the thickness, and the material of the hydrogel film is polyacrylic acid cross-linked by iron ions Obtained; wherein, the depth of the microchannel is 1mm, and the width is 5mm.

[0071] The preparation method of the controllable bidirectional three-dimensional deformation hydrogel film comprises the following steps:

[0072] (1) Clean the silicon wafer with acetone, ethanol, and water in sequence, purge it with nitrogen gas, and place it in a plasma cleaning machine for 1 min. The photoresist SU-8 3050 was drop-coated on the surface of the clean silicon wafer to form a photoresist layer with a thickness of 1mm, and then placed on a 95°C hot stage for heating for 30s. Finally, a silicon-based template (with a length and width of 4 cm×4 cm) with a specific structure was obtained after phot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com