Water-borne paint for bundle-shaped dip coating, and preparation method and construction process thereof

A water-based paint and dip coating technology, applied in the direction of coating, can solve the problems of poor adhesion, mutual adhesion, and poor coating, and achieve the effects of good anti-sinking, improving adhesion and preventing floating color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

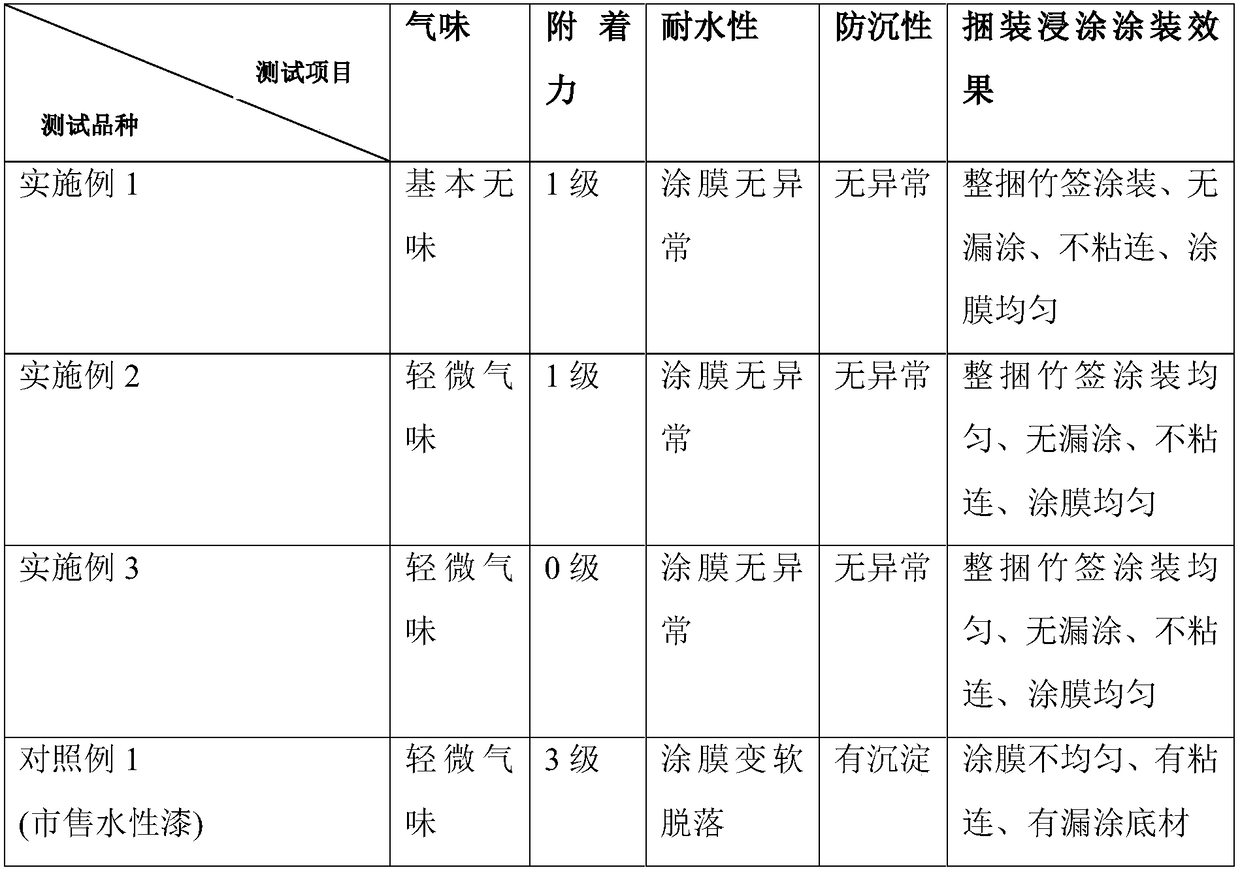

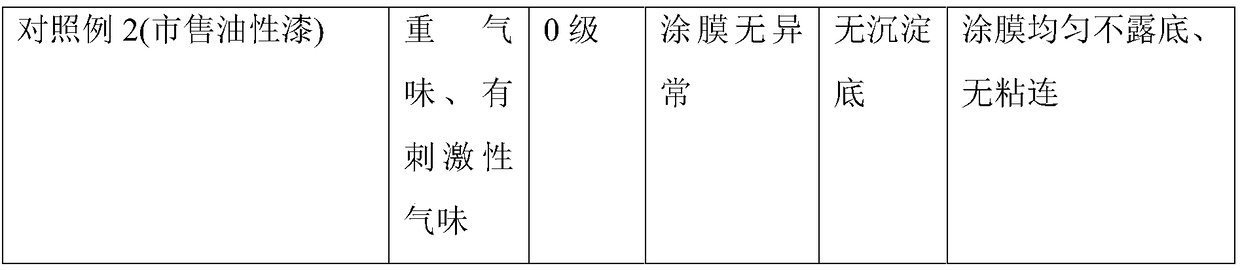

Examples

Embodiment 1

[0027] 1. Preparation of bundle-like water-based paint for dip coating

[0028] Weigh 35 parts of self-crosslinking water-based resin Wanhua 4509 and add it to the stirring tank for use, then add 2.5 parts of propylene glycol butyl ether, 0.2 parts of anti-sedimentation thixotropic agent BYK-420, 0.3 parts of silicone defoamer BYK-024 , 0.3 parts of silicone wetting agent Digo 270, mix and stir evenly, then put the resulting mixture into the stirring tank at a speed of 400-600rpm, and disperse at a speed of 600-800rpm for 5-10min; take 6 parts of water-based red pulp, 4 parts of water-based yellow paste, and 2 parts of water-based black paste to prepare the desired color. Disperse at 800-1200rpm for 5-10min, then add 1 part of Dow ASE-60 thickener, 0.1 part of Dow 342 fungicide, 0.1 part of preservative 586 and 45 parts of deionized water into the stirring tank, Disperse at 600-800rpm for 5-10 minutes to obtain bundle-like dip-coating water-based paint.

[0029] 2. Construct...

Embodiment 2

[0032] 1. Preparation of bundle-like water-based paint for dip coating

[0033] Weigh 40 parts of self-crosslinking water-based resin Oubaodi AC3630 and add it to the stirring tank for use. Then add 2.5 parts of dipropylene glycol butyl ether, 0.25 parts of anti-sedimentation thixotropic agent BYK-420, 0.3 parts of silicone defoamer BYK- 024. Mix and stir 0.25 parts of silicone wetting agent Digo 270, then put the resulting mixture into a stirring tank at a speed of 400-600 rpm, and disperse at a speed of 600-800 rpm for 5-10 minutes; take 5 parts of water-based Red paste, 6 parts of water-based yellow paste, and 1 part of water-based black paste are used to prepare the desired color. Disperse at 800-1200rpm for 5-10 minutes, then put 1 part of Dow ASE-60 thickener, 0.1 part of Dow 342 fungicide, 0.1 part of preservative 586 and 40 deionized water into the stirring tank in turn, at 600 Disperse for 5-10 minutes at ~800rpm to obtain a water-based paint for dipping in bundles. ...

Embodiment 3

[0037] 1. Preparation of bundle-like water-based paint for dip coating

[0038] Weigh 25 parts of self-crosslinking water-based resin Oubaodi AC3630 and 25 parts of self-crosslinking water-based resin Wanhua 4509 into the stirring tank for use. Then add 6 parts of dipropylene glycol methyl ether, 0.5 parts of anti-settling thixotropic agent BYK -420, 0.5 parts of silicone defoamer BYK-024, 0.3 parts of silicone wetting agent Digo 270 are mixed and stirred evenly, and then the resulting mixture is put into the stirring tank at a speed of 400~600rpm. Disperse at 800rpm for 5-10 minutes; take 5 parts of water-based red paste, 6 parts of water-based yellow paste, and 1 part of water-based black paste to prepare the desired color. Disperse at 800-1200rpm for 5-10 minutes, then add 1 part of Dow ASE-60 thickener, 0.3 part of Dow 342 fungicide, 0.3 part of preservative 586 and 29.1 parts of deionized water into the stirring tank in sequence. Disperse at 600-800rpm for 5-10 minutes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com