7-series aluminum alloy profile and preparation method thereof

A technology of aluminum alloy profile and mass percentage, which is applied in the field of aluminum alloy, can solve the problems of general toughness and corrosion resistance strength, achieve high mechanical properties and fracture toughness values, improve yield strength and tensile strength, and improve corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] On the other hand, an embodiment of the present invention provides a method for preparing a 7-series aluminum alloy profile, which includes the following steps:

[0024] S1. Alloy smelting: smelting aluminum raw materials and other alloy raw materials into a melt, sampling and analyzing, and controlling the elemental composition of the melt in terms of mass percentage: Si: ≤0.06%, Fe: ≤0.08%, Cu: 2.10-2.40 %, Mg: 1.90-2.10%, Mn: ≤0.05%, Cr: ≤0.02%, Zn: 7.85-8.25%, Ti: ≤0.06%, Zr: 0.10-0.16%, Be: 0.002-0.005%, other individual Element ≤ 0.030%, the total amount of other impurity elements ≤ 0.100%, the balance is Al;

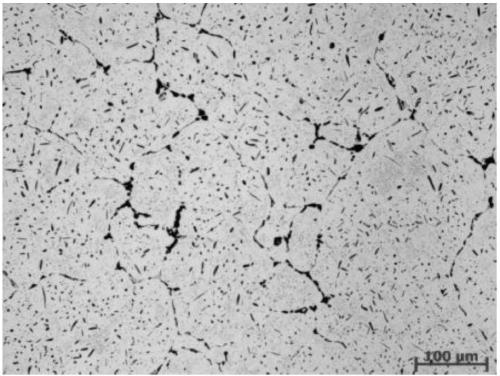

[0025] Among them, aluminum raw materials include 7055 aluminum alloy scrap and 99.9% remelted aluminum ingots. The purpose of adding a certain proportion of 7055 aluminum alloy waste is to have more fine "crystal nuclei" in the aluminum alloy melt, to obtain a more uniform and finer ingot, and to provide better raw materials for improving the fracture tough...

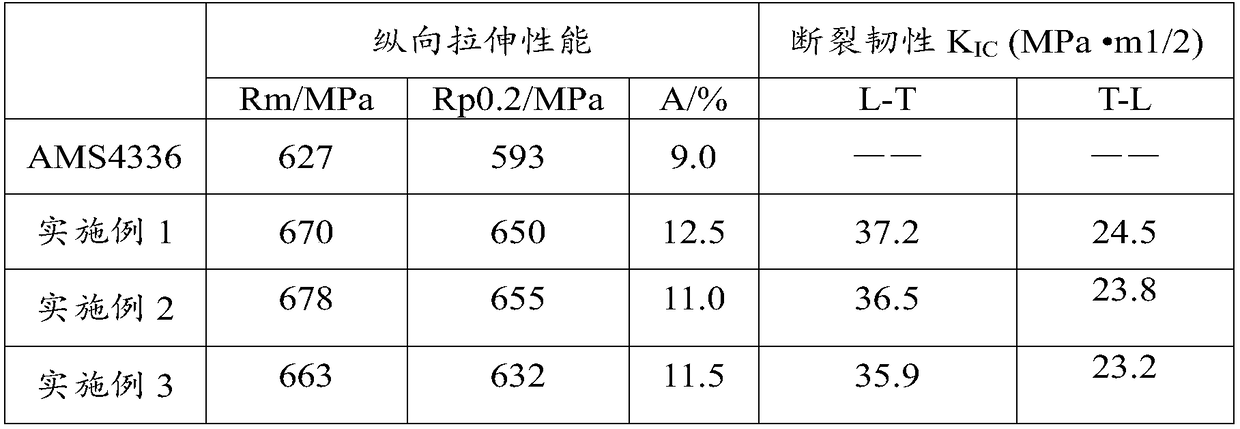

Embodiment 1

[0059] This embodiment provides a 7-series aluminum alloy profile, which is prepared by the following preparation method:

[0060] Raw materials are prepared according to the weight fraction composition of alloy elements of 7055 aluminum alloy: Si: 0.06%, Fe: 0.05%, Cu: 2.26%, Mg: 2.10%, Mn: 0.05%, Cr: 0.01%, Zn: 8.15%, Ti: 0.04%, Zr: 0.13%, Be: 0.003%, other individual elements ≤ 0.030%, the total amount of other impurity elements ≤ 0.100%, the balance is Al, 35% of 7055 aluminum alloy extrusion waste and aluminum content is 99.9% The remelted aluminum ingots are added into the melting furnace together. After the molten aluminum is melted, other alloy element components are added in turn for melting. The melting temperature is 745°C, so that the raw materials are completely melted to obtain a 7055 aluminum alloy melt; The body is transferred to the holding furnace and refined in the furnace at 740°C. The STAS refining process is adopted. The proportion of argon-chlorine mixed...

Embodiment 2

[0067] This embodiment provides a 7-series aluminum alloy profile, which is prepared by the following preparation method:

[0068] Raw materials are prepared according to the weight fraction composition of alloy elements of 7055 aluminum alloy: Si: 0.05%, Fe: 0.08%, Cu: 2.39%, Mg: 1.90%, Mn: 0.04%, Cr: 0.02%, Zn: 8.01%, Ti: 0.06%, Zr: 0.14%, Be: 0.002%, other individual elements ≤ 0.030%, the total amount of other impurity elements ≤ 0.100%, the balance is Al, 35% of 7055 aluminum alloy extrusion waste and aluminum content is 99.9% The remelted aluminum ingots are added into the melting furnace together. After the molten aluminum is melted, other alloy element components are added in turn for melting. The melting temperature is 745°C, so that the raw materials are completely melted to obtain a 7055 aluminum alloy melt; The body is transferred to the holding furnace and refined in the furnace at 735°C. The STAS refining process is adopted. The proportion of argon-chlorine mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com