Heat exchanger diagnosing method

A technology for heat exchangers and process controllers, which is applied in the field of diagnosis of the degree of dirtiness of heat exchangers, and can solve problems such as reduced heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

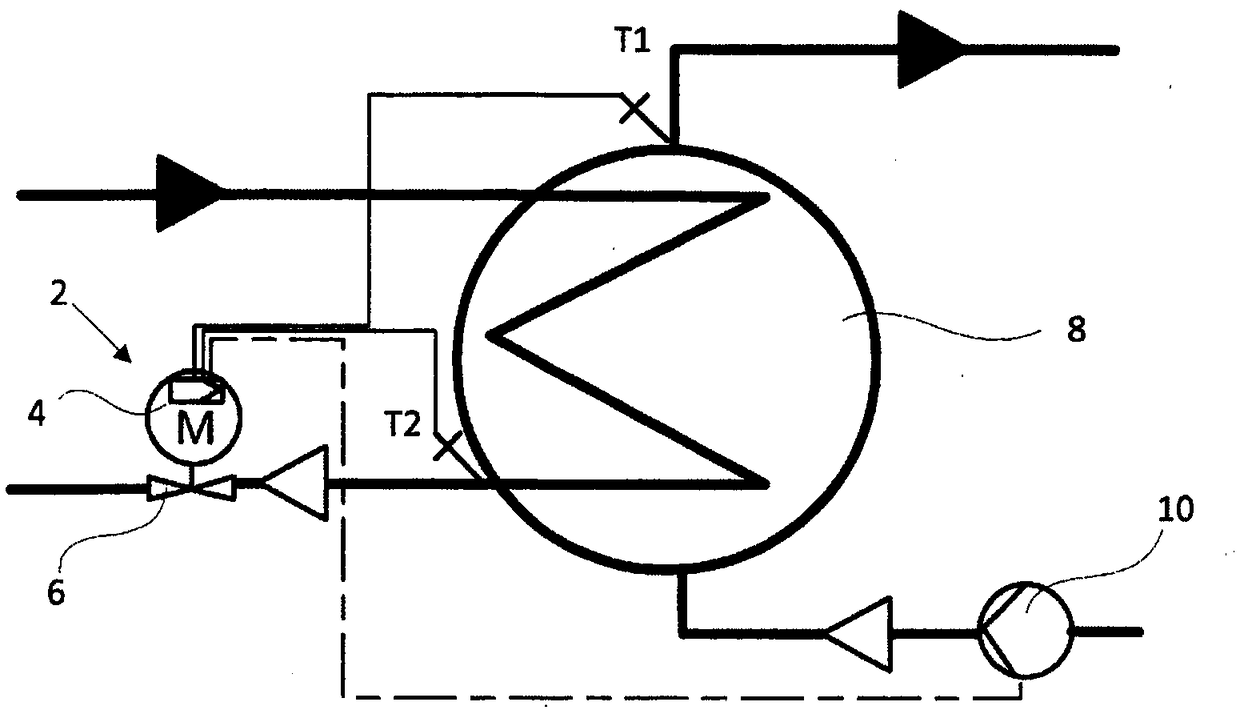

[0044] figure 1 A schematic diagram of a district heating application utilizing a process controller 4 and a controllable regulating valve 6 controlled by the process controller 4 is shown. The regulating valve 6 is connected to the heat exchanger 8 and obtains the initial flow temperature T1 of the user circuit and the return flow temperature T2 of the piping circuit as measurement parameters. Optionally, a pump 10 is connected to the process control drive 2 in the consumer circuit, which provides further control possibilities. The process controller 4 adjusts the regulating valve 6 to the theoretical heat transfer efficiency. The mass flow in the piping circuit required for the theoretical heat transfer efficiency is analyzed as a measure for the degree of fouling of the heat exchanger 8 . exist figure 1 In the example figure, the process control driving mechanism 2 is used in combination with the regulating valve 6 for heating control of the initial flow temperature of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com