Corrosion experiment device and method capable of controlling temperature and humidity for high-voltage electric field environment

A high-voltage electric field and environmental corrosion technology, which is applied to measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as personal safety hazards, high-voltage power grid material life, and factory production problems, so as to improve safety and guarantee The effect of long-term stable and safe operation and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

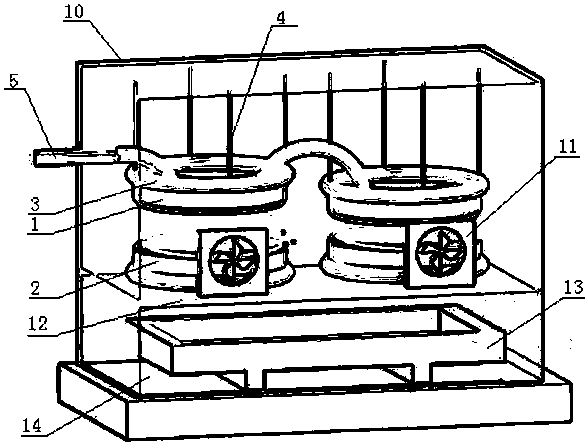

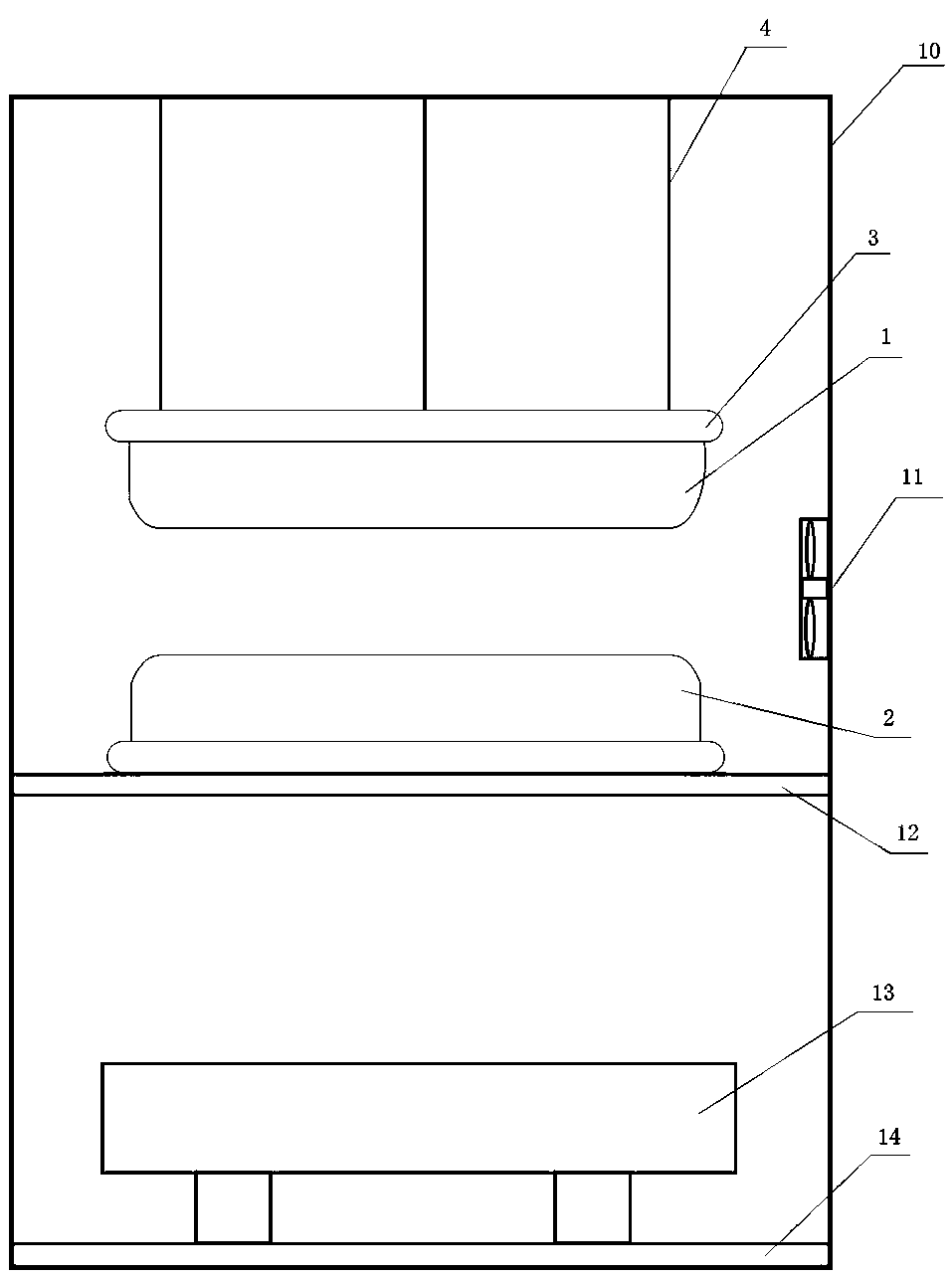

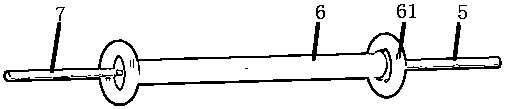

[0049] Example 1: A 5052 aluminum alloy with a specification of 20mm×20mm×2mm was used as a corrosion sample, and the sample was packaged, and only the surface of 20mm×20mm was exposed as a corrosion area. The voltage of the light transformer is adjusted to 20KV, and the distance between the upper and lower plates is adjusted to 100mm and 50mm. At this time, the strengths of the two electric fields are 200KV / m and 400KV / m respectively. Place 2×8 samples on two sample stages for corrosion. Precisely drop the corrosion solution through a 100 μL pipette, and make the corrosion solution evenly covered. 12 hours is a cycle cycle. After 30 days of corrosion, a scanning electron microscope test was performed.

[0050] Such as Figure 5 As shown in Figure a, under the electric field strength of 0KV / m, there are a few corrosion and oxidation products on the surface of the aluminum alloy, and no cracks appear on the surface of the substrate. In Figure b, under the electric field st...

example 2

[0051] Example 2: Use carbon steel with a specification of 30mm×30mm×2mm as the corrosion sample, encapsulate the sample, and only expose the surface of 30mm×30mm as the corrosion area. The voltage of the light transformer is adjusted to 40KV, and the distance between the upper and lower plates is adjusted to 100mm and 50mm. At this time, the strengths of the two electric fields are 400KV / m and 800KV / m respectively. Place 2×4 samples on two sample stages for corrosion. Precisely drop the corrosion solution through a 100 μL pipette, and make the corrosion solution evenly covered. 12 hours is a cycle cycle. The device was operated stably for 60 cycles, and the results obtained were similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com