Measuring device and measuring method of multiple-parameter distribution and characterization for surface scattering of high reflection lens

A technology of surface scattering and measurement device, which is applied in measurement device, measurement of scattering characteristics, analysis of materials, etc., can solve the problem of not being able to detect the backscattering rate and forward scattering rate of high-reflecting mirrors of laser gyro at the same time, and achieve high detection efficiency. , Improve the quality of assembly, the effect of strong beam adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the drawings and embodiments.

[0023] The present invention combines the detection of existing optical element surface flaws and laser gyroscope backscattering rate, designs a kind of can detect laser gyroscope high reflective mirror surface flaws and can measure the backscattering rate and forward scattering rate of selected area at the same time rate detection device.

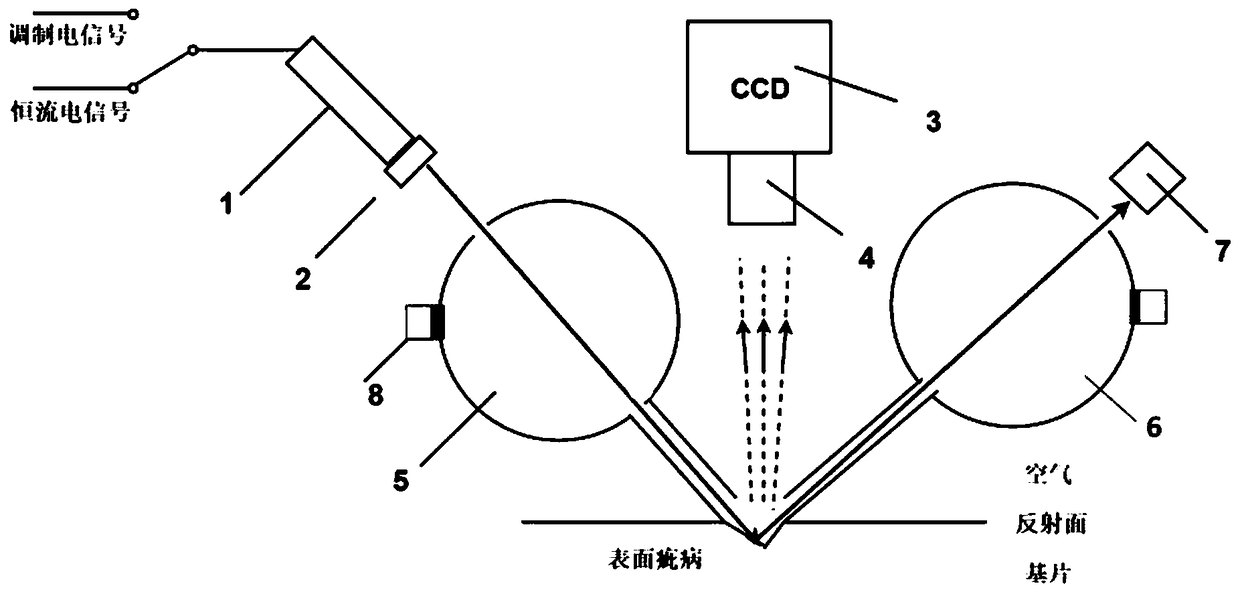

[0024] refer to figure 1 , a highly reflective mirror surface scattering multi-parameter distribution characterization measurement device is composed of a semiconductor laser 1, a CCD imaging system, two integral scattering rate measurement components and a light trap 7, and the CCD imaging system includes a CCD camera 3 and a microscope lens 4. A beam switching drum 2 and a back integrated scatter rate measurement component 5 are sequentially arranged on the incident light path of the laser beam, and a forward integrated scatt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com