Lithium battery packaging and insulation testing device and packaging and insulation testing method

A technology for insulation testing and lithium batteries, which is applied in the direction of testing dielectric strength, non-aqueous electrolyte batteries, and electrolyte battery manufacturing. It can solve the problems of low detection efficiency, improve packaging efficiency, improve test accuracy, and improve test efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

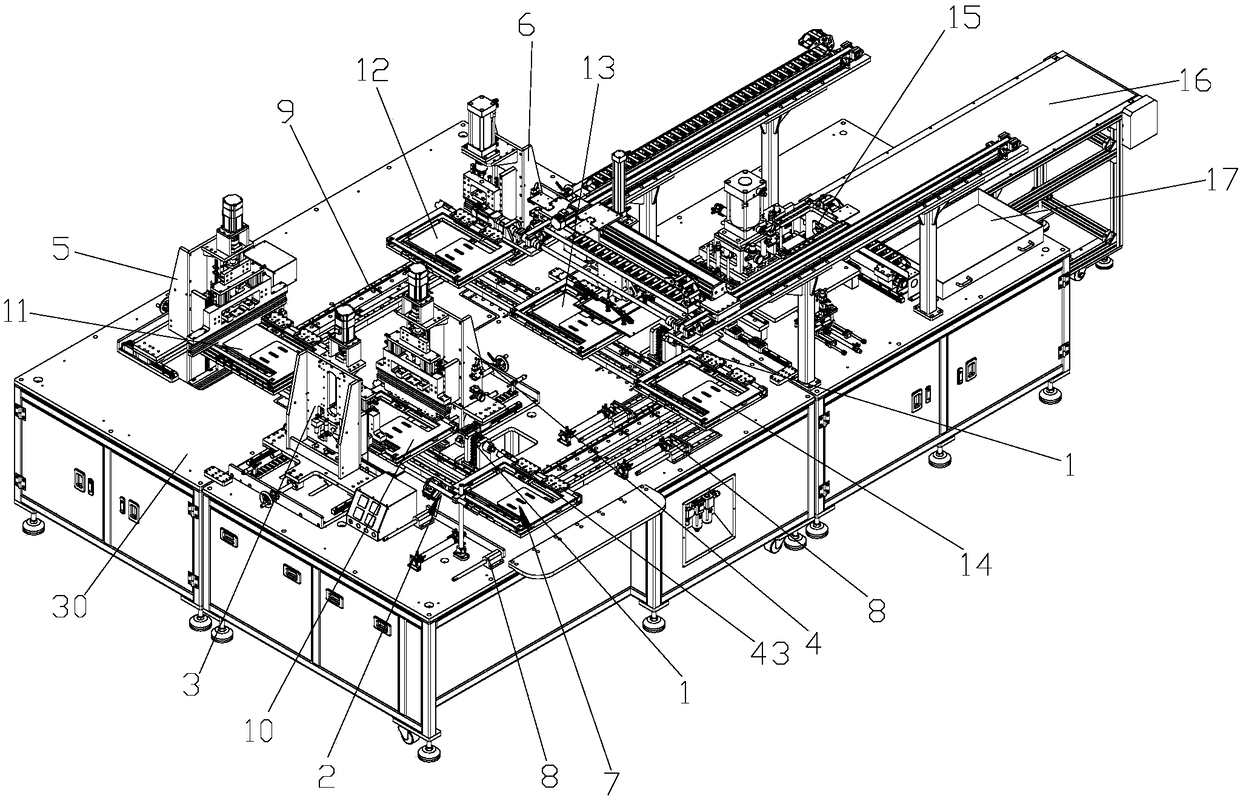

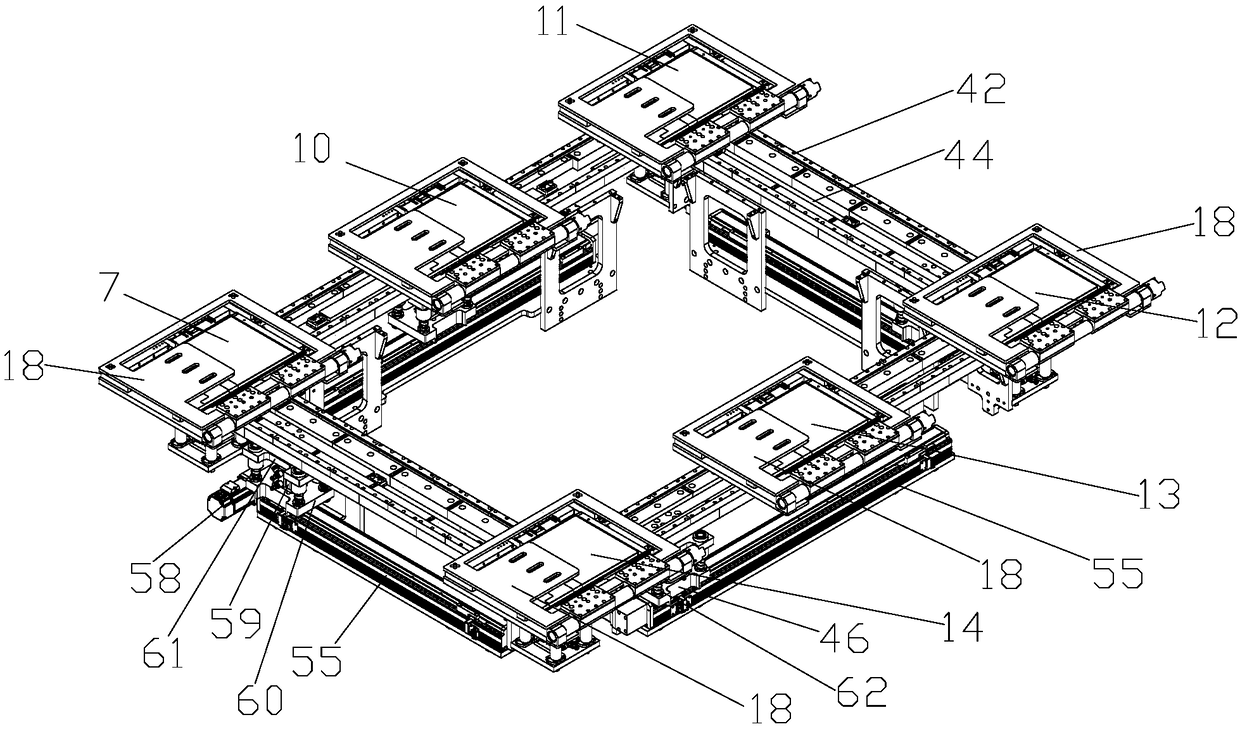

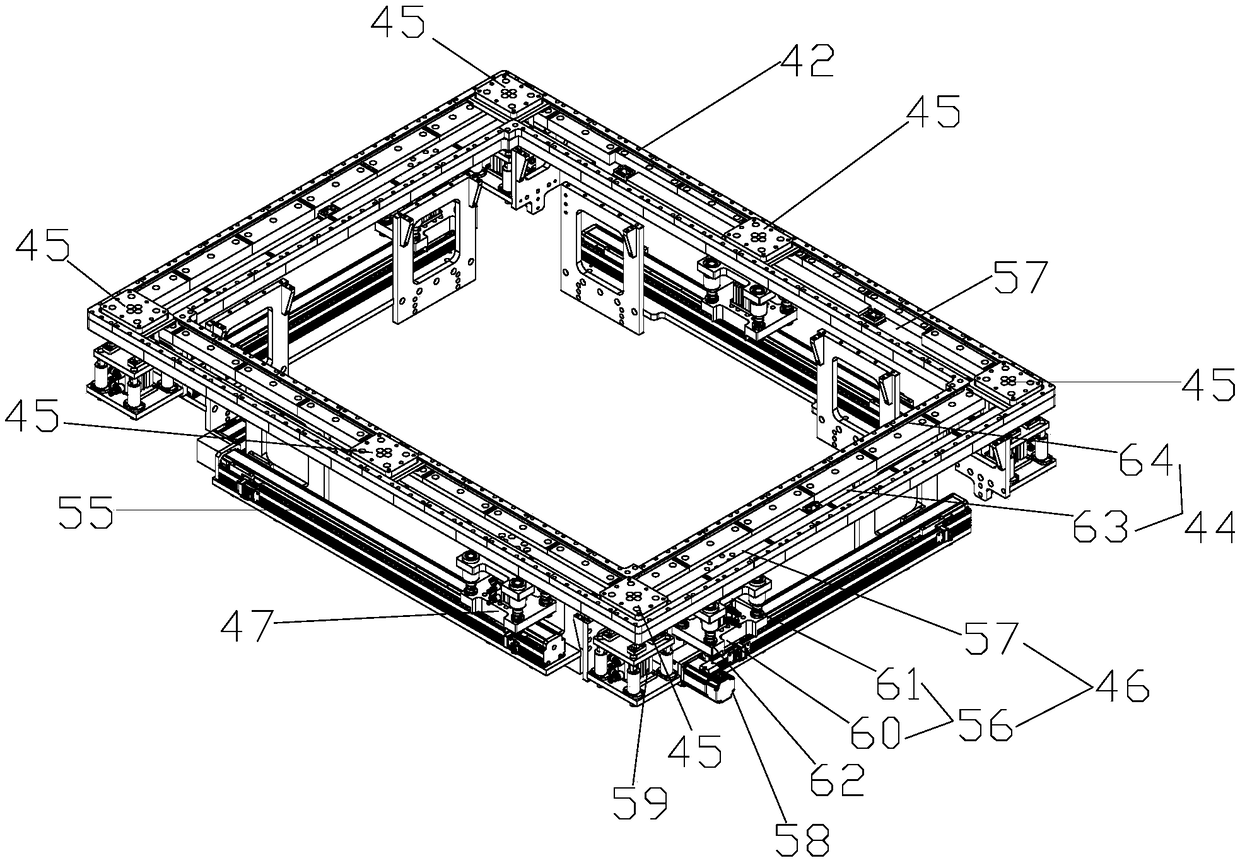

[0076] Such as figure 1 As shown, the packaging and insulation testing equipment for lithium batteries of the present invention is used to package lithium batteries with bipolar ears on both sides. The packaging and insulation testing equipment includes: mold opening and closing device 1, code scanning device 2, top The sealing device 4, the bottom sealing device 3, the side sealing device 5, the corner sealing device 6, the cutting edge insulation testing device 15, and the reflow device 9. Among them, the mold opening and closing device 1 clamps the mold opening positioning fixture 18; the code scanning device 2 scans the code to identify the negative electrode of the lithium battery cell in the mold positioning fixture 18; the top sealing device 4. After the code scanning device 2, the top and bottom sealing position 10 encapsulates the top of the lithium battery cell in the scanning positioning fixture 18; the bottom sealing device 3 is arranged opposite to the top sealing d...

Embodiment 2

[0079] On the basis of Embodiment 1, the packaging and insulation testing equipment for lithium batteries of the present invention is used for packaging and insulation testing of lithium batteries with bipolar ears on one side. The packaging and insulation testing equipment includes: mold opening and closing device 1 , Code scanning device 2, top sealing device 4, bottom sealing device 3, side sealing device 5, corner sealing device 6, edge trimming insulation testing device 15 and reflow device 9. Among them, the mold opening and closing device 1 clamps the mold opening positioning fixture 18; the code scanning device 2 scans the code to identify the negative electrode of the lithium battery cell in the mold positioning fixture 18; the top sealing device 4. After the code scanning device 2, the top and bottom sealing position 10 encapsulates the top of the lithium battery cell in the scanning positioning fixture 18; the bottom sealing device 3 is arranged opposite to the top se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com