System for chemical and/or electrolytic surface treatment

A surface treatment, chemical technology, applied in the field of systems for chemical and/or electrolytic surface treatment, capable of solving problems such as suboptimal pre-wetting methods and achieving uniform material deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

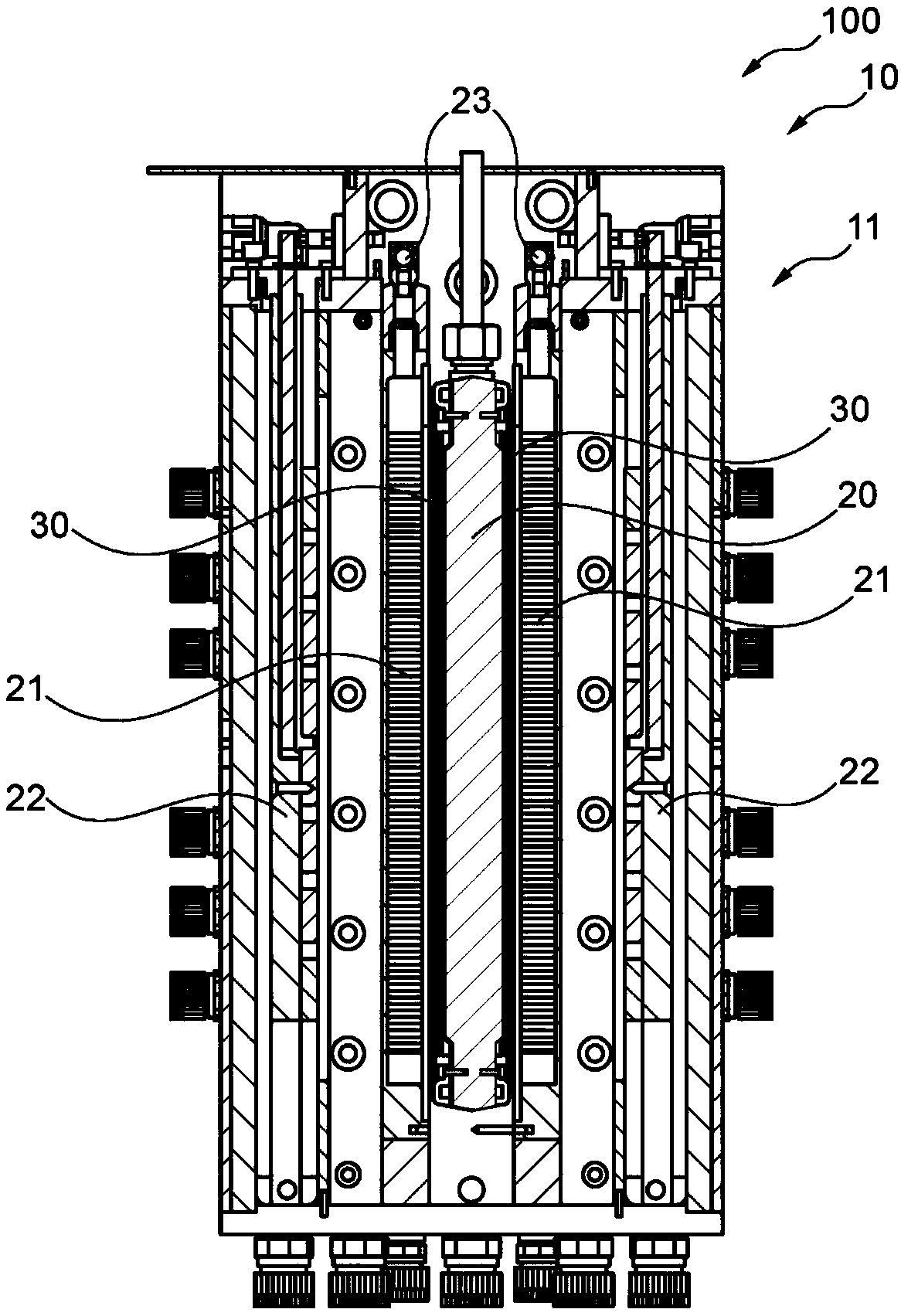

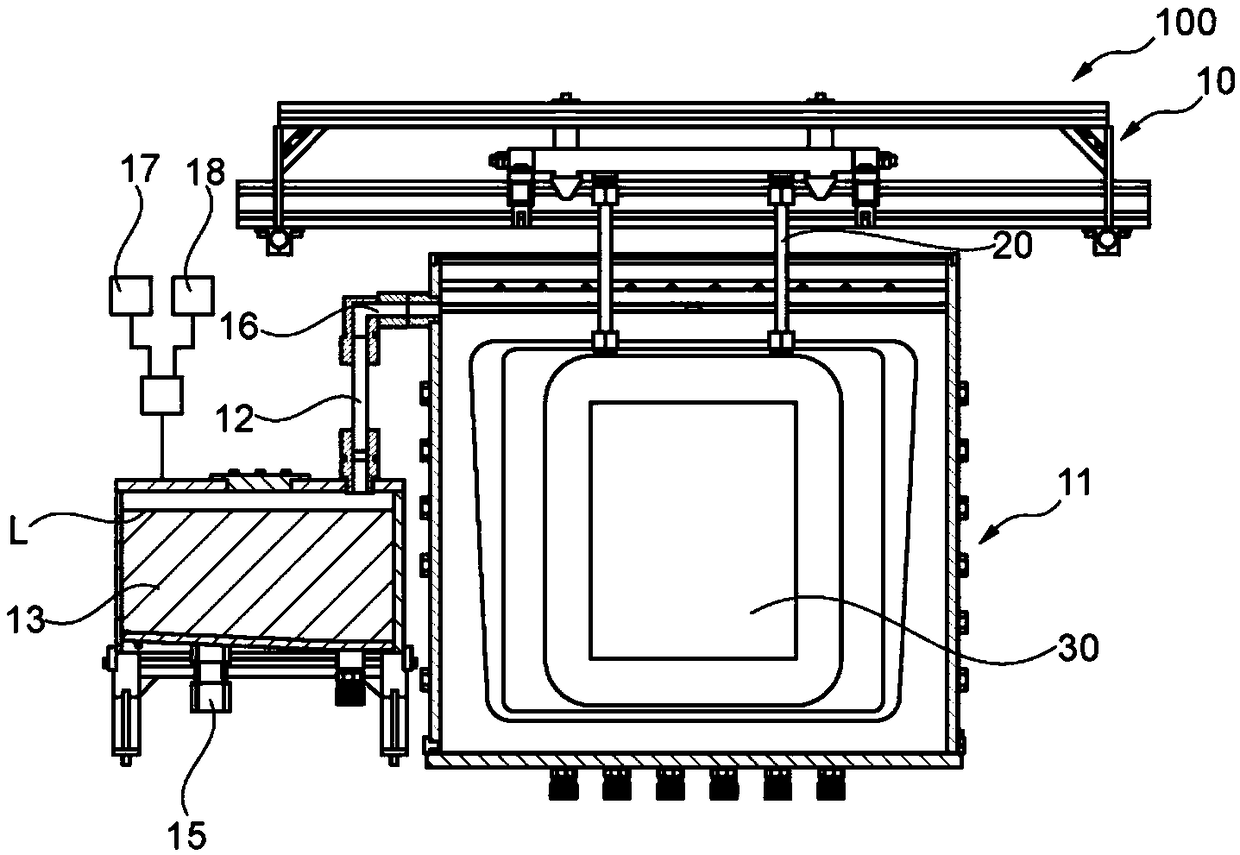

[0053] figure 1 , image 3 and Figure 4 An embodiment of a device 100 according to the invention for chemical and / or electrolytic surface treatment of a substrate 30 in a process fluid is shown schematically and exemplarily. The apparatus 100 for chemical and / or electrolytic surface treatment comprises a substrate holder 20 and a system 10 for chemical and / or electrolytic surface treatment of a substrate 30 in a process fluid.

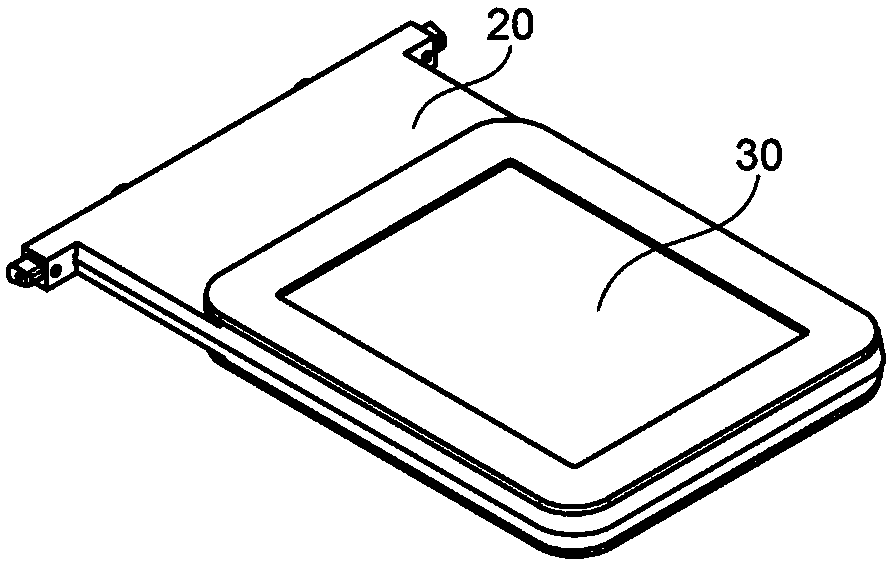

[0054] The substrate holder 20 is in figure 2 shown in and configured to hold a substrate 30 . The substrate holder 20 here holds two substrates, one substrate 30 on each side of the substrate holder 20 . The substrate holder 20 may also be configured to hold only one substrate, which may be processed from one or both sides.

[0055] Such as figure 1 , image 3 and Figure 4 The illustrated system 10 for chemical and / or electrolytic surface treatment of a substrate 30 in a process fluid produces a target flow and current density pattern for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com