Preparation method of composite white oil slurry and preparation method of composite fibers of UHMWPE

A composite fiber and white oil technology, which is applied in the fields of fiber chemical characteristics, melt spinning, rayon manufacturing, etc., can solve the problems of large size, wide particle size distribution of graphene particles, and difficulty in meeting production needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

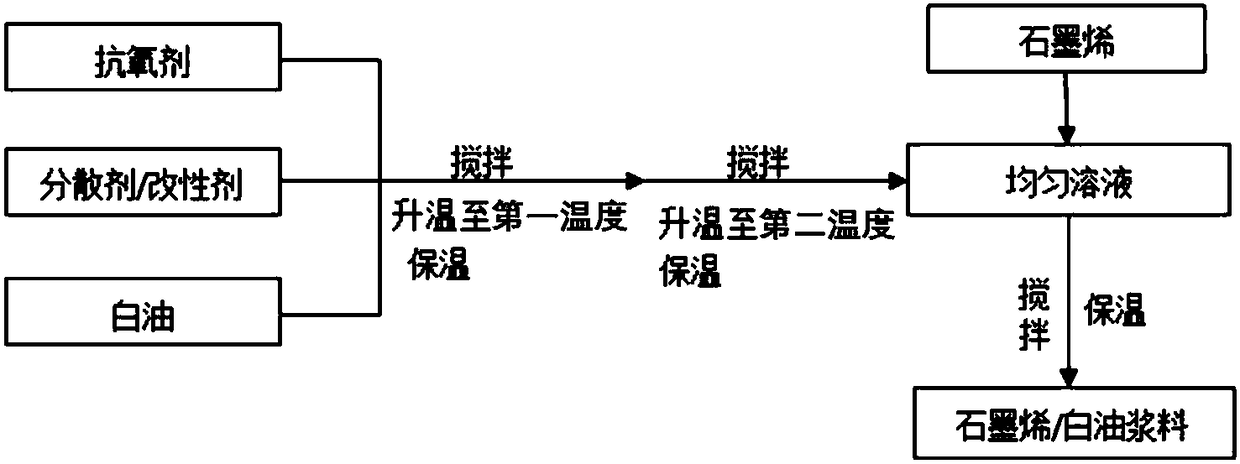

[0079] Preparation of composite paste, see figure 1 :

[0080] (1) Add antioxidant 1010 (0.01kg) and PSS (0.01kg) to white oil (99.97kg), and heat to 80°C for 0.2h while stirring;

[0081] (2) The mixed solution is gradually heated up to 120°C at a heating rate of 20°C / h and kept for 3 minutes until the antioxidant 1010 and PSS are fully dissolved to form a uniform solution;

[0082] (3) Graphene powder (0.01kg) was gradually added to the above solution under high-speed stirring conditions, and kept warm for 2 hours to obtain graphene / white oil slurry.

[0083] Further preparation of composite fibers of UHMWPE:

[0084] (4) Add UHMWPE powder 10kg (graphene accounts for 0.1% of UHMWPE) and white oil 1.14kg in the graphene / white oil slurry that obtains, make pre-spinning liquid, enter in swelling kettle and be heated up to 100 ℃, again After dissolving kettle, feeding kettle, and twin-screw extruder, the temperature is raised from 100°C to 268°C in steps of 100 / 130 / 160 / 210 / 2...

Embodiment 2

[0086] Preparation of composite paste, see figure 1 :

[0087] (1) Antioxidant 1010 (1kg) and SDBS (1kg) were added to white oil (97.99kg), heated to 110°C for 0.5h while stirring;

[0088] (2) The mixed solution is gradually heated up to 130°C at a heating rate of 25°C / h and kept for 5 minutes until the antioxidant 1010 and SDBS are fully dissolved to form a uniform solution;

[0089] (3) Graphene powder (0.01kg) was gradually added to the above solution under high-speed stirring conditions, and kept warm for 4 hours to obtain graphene / white oil slurry.

[0090] Further preparation of composite fibers of UHMWPE:

[0091] (4) Add UHMWPE powder 10kg (graphene accounts for 0.1% of UHMWPE) and white oil 3.12kg in the graphene / white oil slurry that obtains, make pre-spinning liquid, enter in the swelling kettle and be heated up to 100 ℃, again After dissolving kettle, feeding kettle, and twin-screw extruder, the temperature is raised from 100°C to 268°C in steps of 100 / 130 / 160...

Embodiment 3

[0093] Preparation of composite paste, see figure 1 :

[0094] (1) Add antioxidant 164 (1kg) and SDS (0.01kg) to white oil (98.98kg), and heat to 110°C for 0.7h while stirring;

[0095] (2) The mixed solution is gradually heated up to 140°C at a heating rate of 28°C / h and kept for 10 minutes until the antioxidant 164 and SDS are fully dissolved to form a uniform solution;

[0096] (3) Graphene powder (0.015kg) was gradually added to the above solution under high-speed stirring conditions, and kept warm for 5 hours to obtain graphene / white oil slurry.

[0097] Further preparation of composite fibers of UHMWPE:

[0098](4) Add UHMWPE powder 10kg (graphene accounts for 0.15% of UHMWPE) and white oil 2.131kg in the graphene / white oil slurry that obtains, make pre-spinning liquid, enter in swelling kettle and be heated up to 100 ℃, again After dissolving kettle, feeding kettle, and twin-screw extruder, the temperature is raised from 100°C to 268°C in steps of 100 / 130 / 160 / 210 / 24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com