Method for producing electroplated steel sheet and production device therefor

A manufacturing method, steel plate technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of unevenness, increased dissolution, uneven appearance, etc., and achieve the effect of beautiful surface appearance and uniform plating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Examples of the present invention will be described below. The technical scope of the present invention is not limited to the following examples.

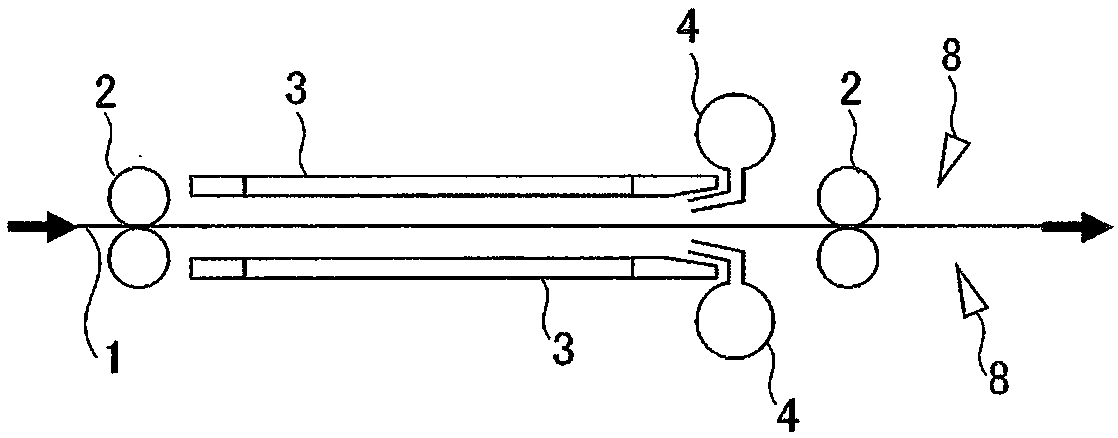

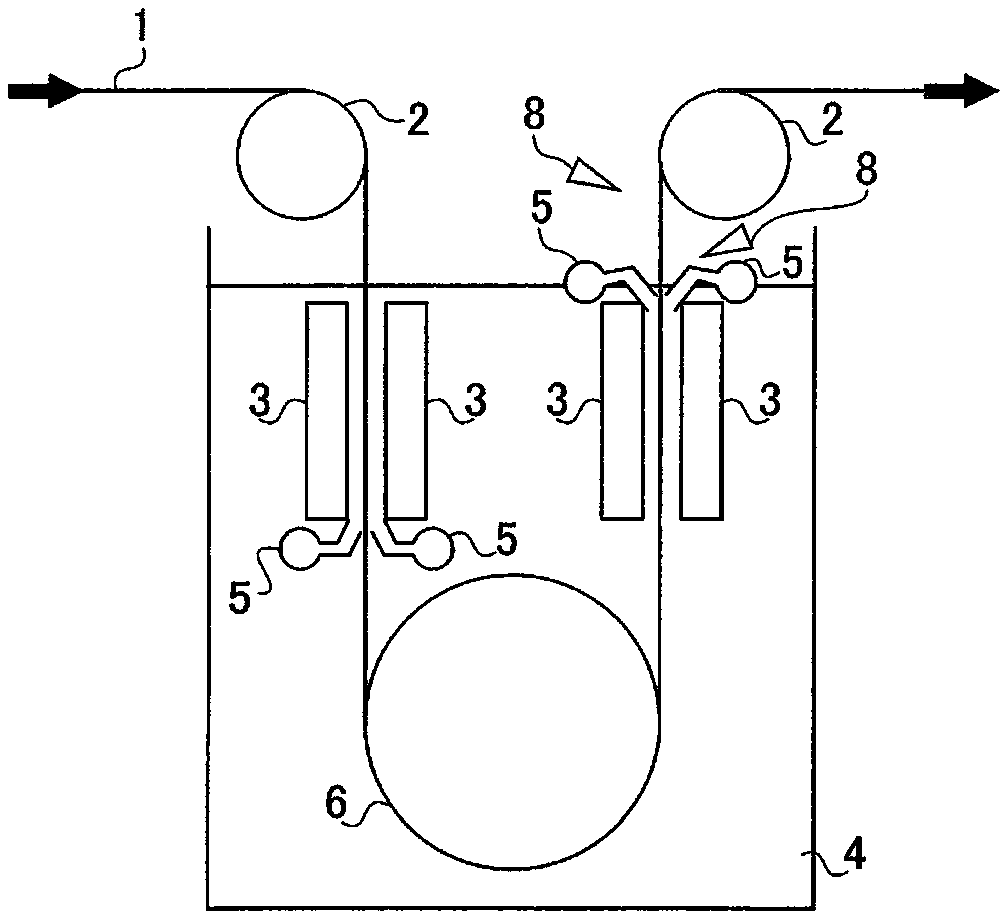

[0088] will use the Figure 1~3 The example of the electroplating tank of the structure shown was electroplated as the example of this invention, and the electroplating steel plate was manufactured. The steel strip 1 is a cold-rolled steel strip with a thickness of 0.5 mm×a width of 1000 mm, and is run at a line speed of 1.83 to 5.0 m / s. The anode electrode 3 is made of titanium, has an iridium oxide film on its current-carrying surface, and has a width substantially covering the steel strip 1 . The plating solution 4 was used by keeping the temperature of 60° C. and using a solution having a different pH and having a zinc sulfate concentration of 400 g / L. For the amount of plating deposition, the lower limit of one side is set to 20g / m 2 conditions of. For the plating thickness, calculate the average value of 10 measur...

Embodiment 2

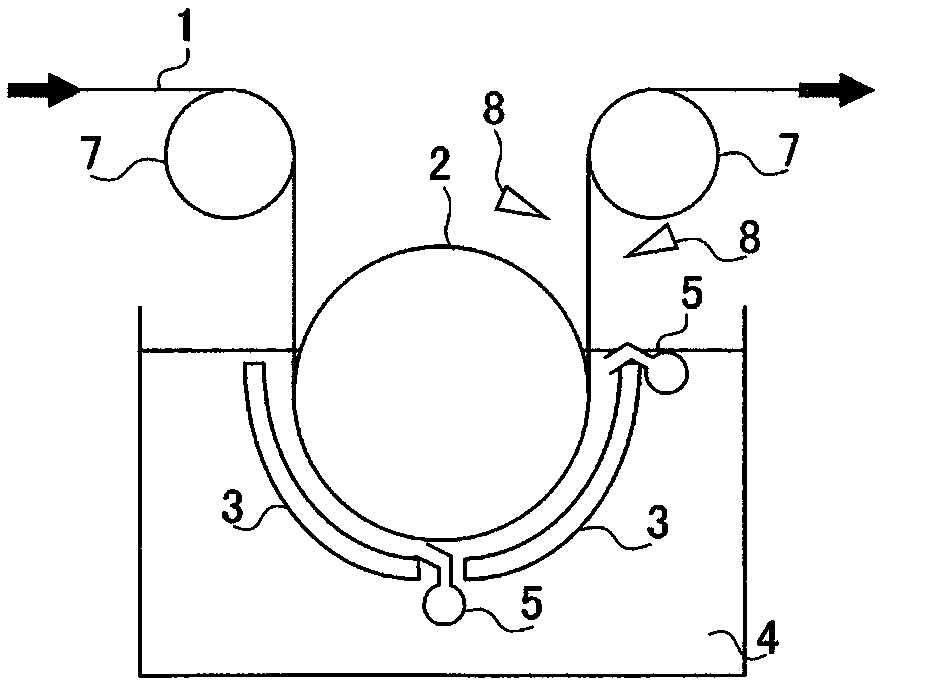

[0095] will use the Figure 4~6 The example of the electroplating tank of the structure shown was electroplated as the example of this invention, and the electroplating steel plate was manufactured. The steel strip 1 is a cold-rolled steel strip with a thickness of 0.5 mm×a width of 1000 mm, and is run at a line speed of 2.07 to 5.0 m / s. The anode electrode 3 is made of titanium, has an iridium oxide film on its current-carrying surface, and has a width substantially covering the steel strip 1 . The plating solution 4 was used by keeping the temperature of 60° C. and using a solution having a different pH and having a zinc sulfate concentration of 400 g / L. For the amount of plating deposition, the lower limit of one side is set to 20g / m 2 conditions of. As the liquid sprayed from the spray nozzle 9, sulfuric acid whose pH was properly adjusted was used.

[0096] For the plating thickness, calculate the average value of 10 measurements at three points in the width direction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com