Plasma processing chamber, potential controlling apparatus, method, program and storage medium

A plasma and potential control technology, applied in the fields of plasma, ion implantation and plating, semiconductor/solid-state device manufacturing, etc. The effect of preventing the reduction of work efficiency, preventing consumption, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0072] First, a plasma processing chamber according to a first embodiment of the present invention will be described.

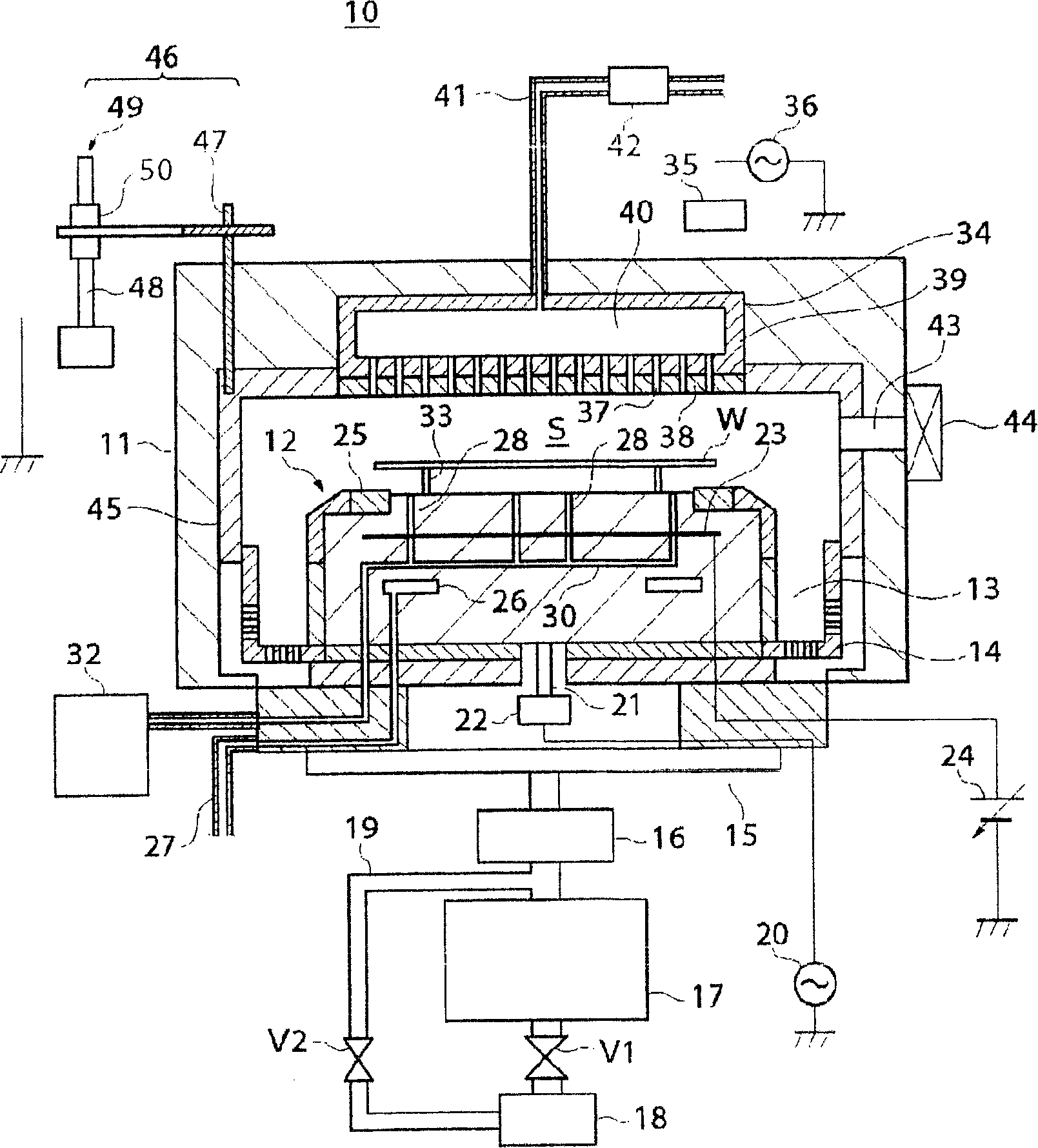

[0073] figure 1 is a cross-sectional view showing a schematic configuration of a plasma processing chamber according to this embodiment. This plasma processing chamber is configured to perform RIE (Reactive Ion Etching) processing and ashing processing on a semiconductor wafer W serving as a substrate.

[0074] figure 1 Among them, the plasma processing chamber 10 has a cylindrical container 11, and in the container 11, a columnar wafer W (hereinafter simply referred to as "wafer W") as a mounting table with a diameter of 300 mm is disposed. base 12.

[0075] In the plasma processing chamber 10 , an exhaust path 13 serving as a flow path for exhausting gas molecules above the susceptor 12 to the outside of the vessel 11 is formed through the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com