Semi-permeable membrane support material

A technology of supporting material and semipermeable membrane, applied in the field of semipermeable membrane supporting material and its preparation, can solve the problems of not effectively solving the stretching ratio, too large, unable to provide solutions, etc., to achieve guaranteed performance, convenient processing, large Effect of CD on Tensile Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

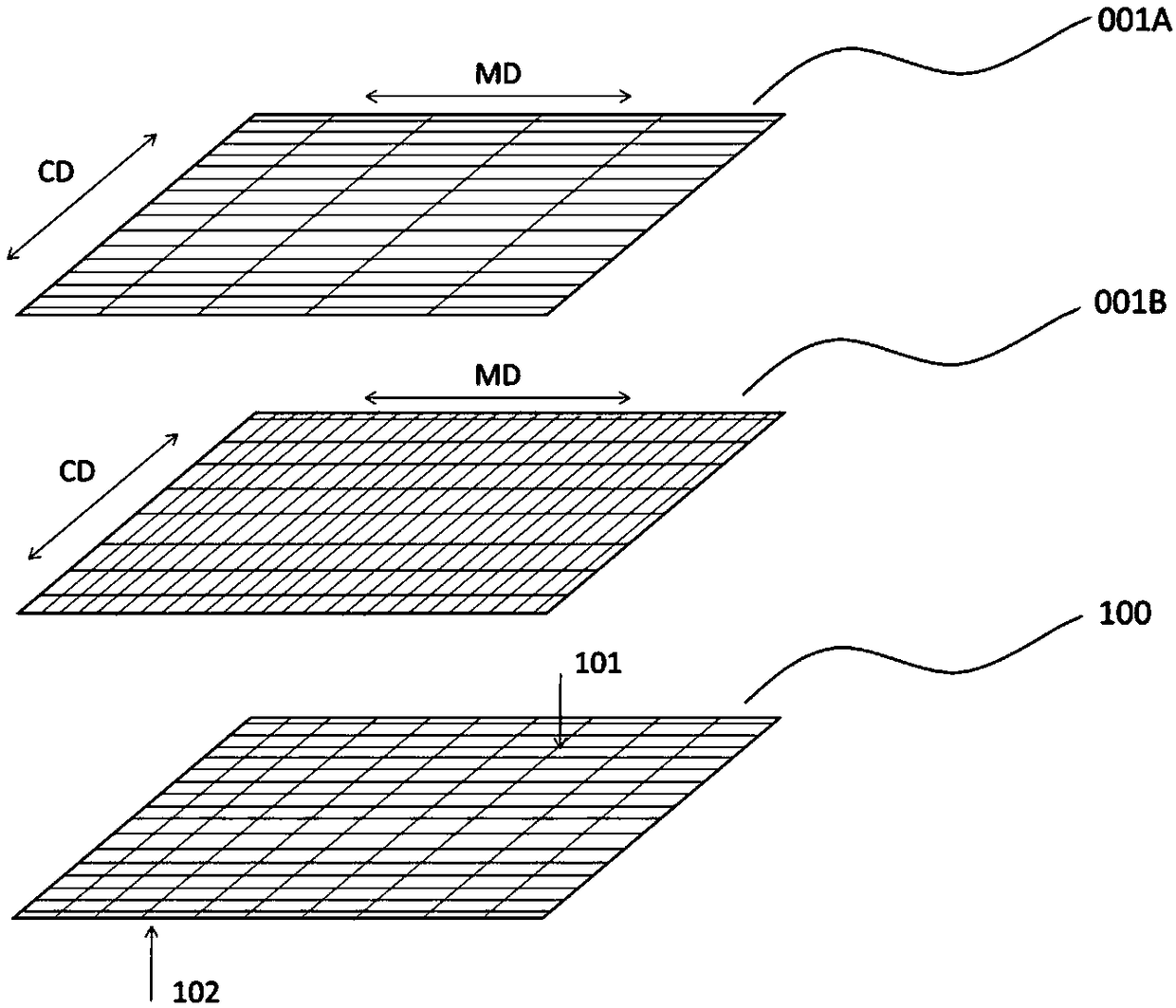

[0075] When preparing the support material, the non-woven fabric layers that have not been hot-pressed are combined and superimposed in pairs, and then hot-pressed.

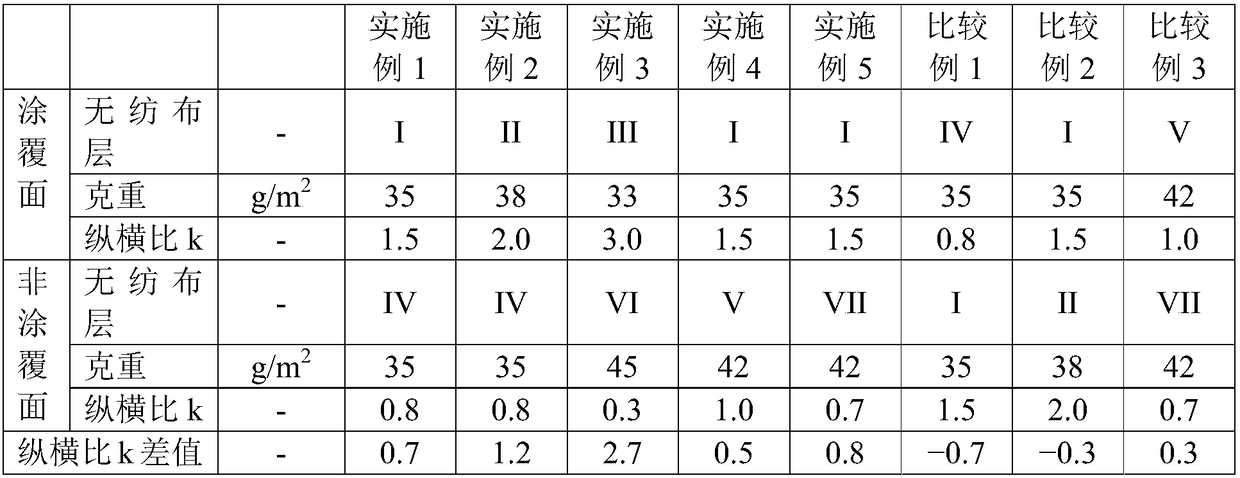

[0076] The non-woven fabric layer I and the non-woven fabric layer IV are superimposed, the hot pressing temperature is 240° C., and the pressure is 3000 N / cm. A semi-permeable membrane support material is obtained. Gram weight is 70g / m 2 , the aspect ratio k is 1.32. Wherein, the side where the non-woven fabric layer I is located is the coated surface.

Embodiment 2

[0078] When preparing the support material, the non-woven fabric layers that have not been hot-pressed are combined and superimposed in pairs, and then hot-pressed.

[0079] The non-woven fabric layer II and the non-woven fabric layer IV are superimposed, the hot pressing temperature is 240° C., and the pressure is 2300 N / cm. A semi-permeable membrane support material is obtained. Gram weight is 73g / m 2 , the aspect ratio k is 1.73. Wherein, the side where the non-woven fabric layer II is located is the coated side.

Embodiment 3

[0081] When preparing the support material, the non-woven fabric layers that have not been hot-pressed are combined and superimposed in pairs, and then hot-pressed.

[0082] The non-woven fabric layer III and the non-woven fabric layer VI are superimposed, the hot pressing temperature is 320° C., and the pressure is 2500 N / cm. A semi-permeable membrane support material is obtained. Gram weight is 78g / m 2 , the aspect ratio k is 2.62. Wherein, the side where the non-woven fabric layer III is located is the coated side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com