Device and method utilizing laser light to induce compound stamping formation

A stamping forming and laser-induced technology, which is applied in the field of stamping forming of fine parts, can solve the problems of few scholars and achieve the effect of small laser energy, large forming depth and good forming area precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

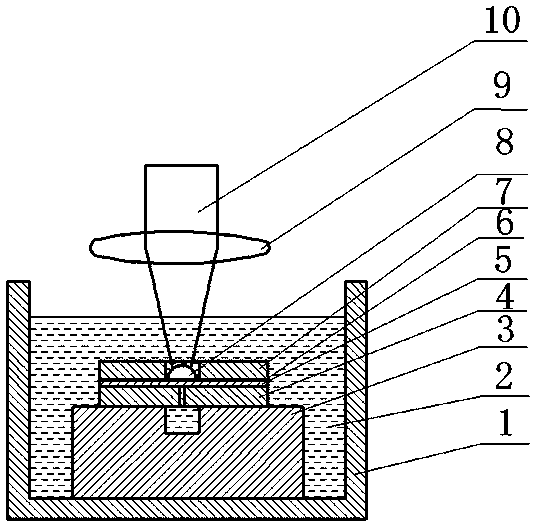

[0020] like figure 1 As shown in the figure, a device for composite stamping and forming workpieces using laser-induced plasma shock waves and cavitation collapse shock waves, including a water tank 1 containing a liquid 2, a spacer 3, a molding micro-mold 4, a blank holder 7, and a lens group 9 and laser, the spacer 3, the blank holder 7 and the forming micro-mold 4 are all located in the liquid 2 of the water tank 1, the workpiece 5 is located above the forming micro-mould 4, and the blank holder 7 is located above the workpiece 5, the middle of the blank holder 7 has a longitudinal first through hole, the forming micro-mold 4 has a second through hole, and the bottom of the forming micro-mold 4 passes through the second through hole The cavity on the spacer block 3 is directly connected to the liquid 2 in the water tank 1 ; the lens group 9 is arranged ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com