Multi-axis servo drive control system and robot system

A robot system and servo drive technology, applied in general control systems, control/regulation systems, program control manipulators, etc., can solve complex and unfavorable maintenance and management of motor servo drive control systems, chaotic wiring between robots and electrical control cabinets, and problems Complexity and other issues, to achieve the effect of reducing wiring costs, facilitating installation and maintenance, and simple wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiment of multi-axis servo drive control system:

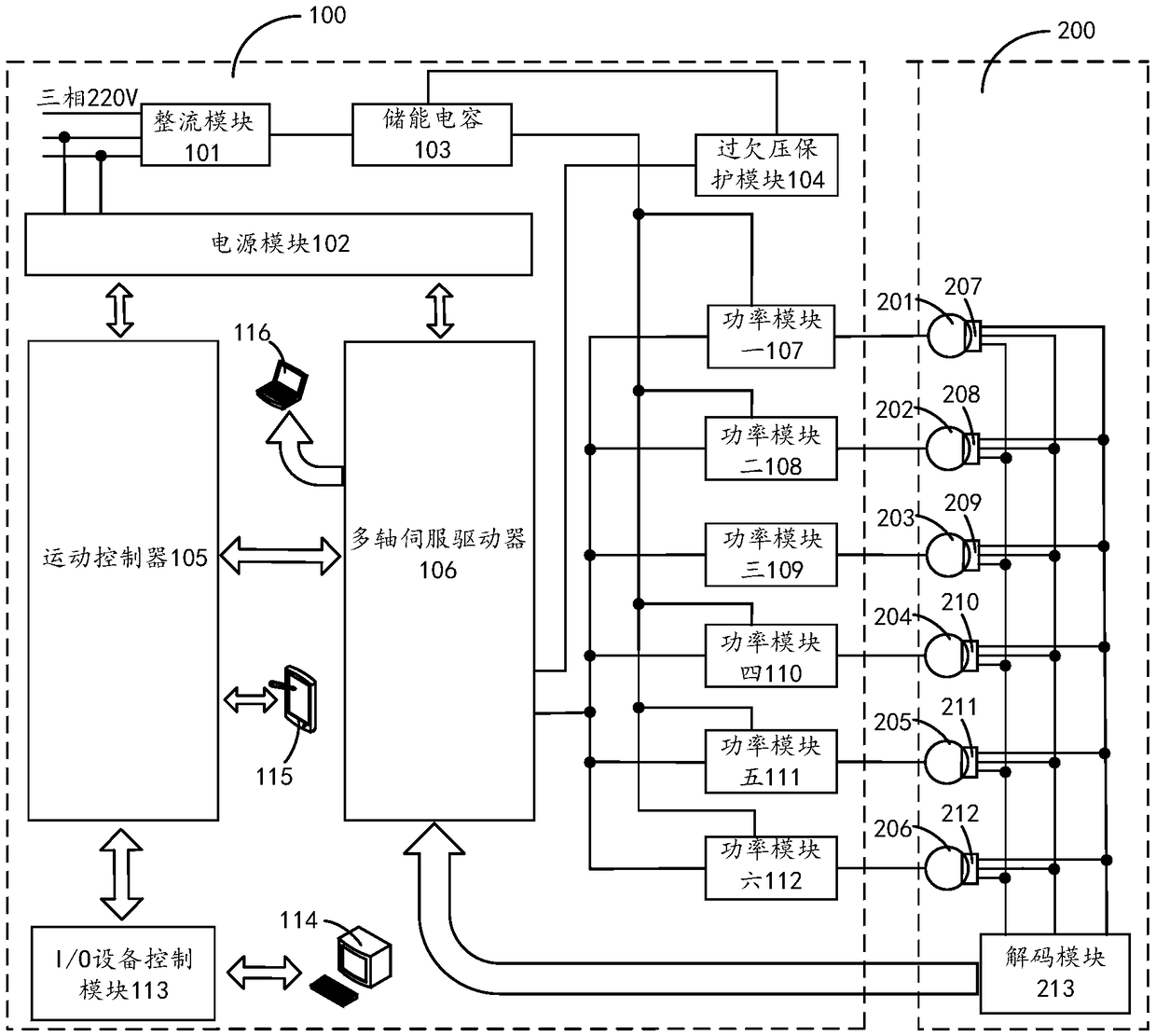

[0036] The multi-axis servo drive control system of this embodiment includes an electrical control cabinet 100 and an execution device 200, such as the electrical control cabinet 100 and a manipulator.

[0037] The electrical control cabinet 100 is equipped with a three-phase power rectifier module 101, a power module 102, an energy storage capacitor 103, an overvoltage and undervoltage protection module 104, a motion controller 105, a multi-axis servo driver 106, and six power modules, six power modules They are power module one 107 , power module two 108 , power module three 109 , power module four 110 , power module five 111 and power module six 112 .

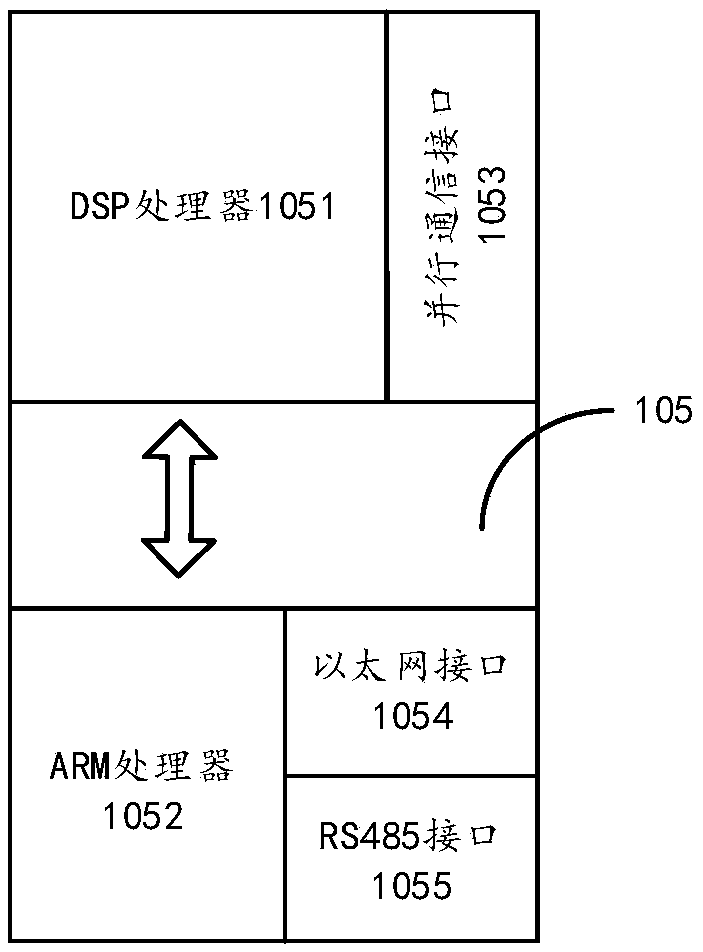

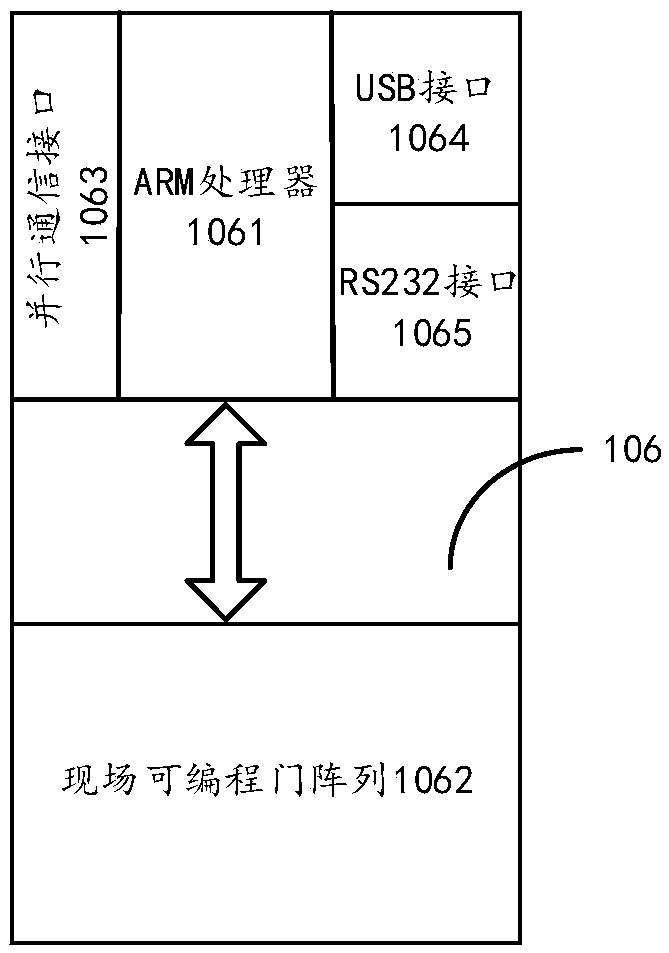

[0038] The multi-axis servo driver 106 includes a first chip on chip, and the motion controller 105 includes a second chip on chip, and the first chip on chip and the second chip on chip are integrated on the same printed circuit board (Printed circuit board, PCB)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com