Method for preparing precipitated silica by continuous method

A technology of precipitated silica and continuous method, which is applied in the direction of silica, silica, etc., can solve the problems of poor acid-base mixing uniformity and product performance degradation, and achieve high production efficiency, stable product performance, and consistent performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

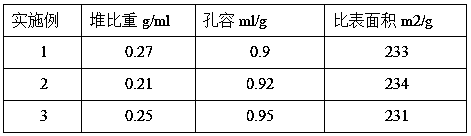

Embodiment 1

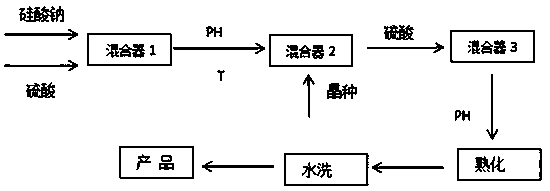

[0019] A method for preparing precipitated silica by a continuous method, comprising the steps of:

[0020] (1) Preparation of seed crystals: prepare 10kg of 3wt% sodium silicate aqueous solution, pass through a cation exchange resin, control the pH of the silicic acid solution at the ion exchange outlet to 4.2, and then use sodium silicate to adjust the pH of the silicic acid solution after exchange to 9.0 , add to the reaction tank and raise the temperature to 85°C, keep it warm for 30min, and set it aside;

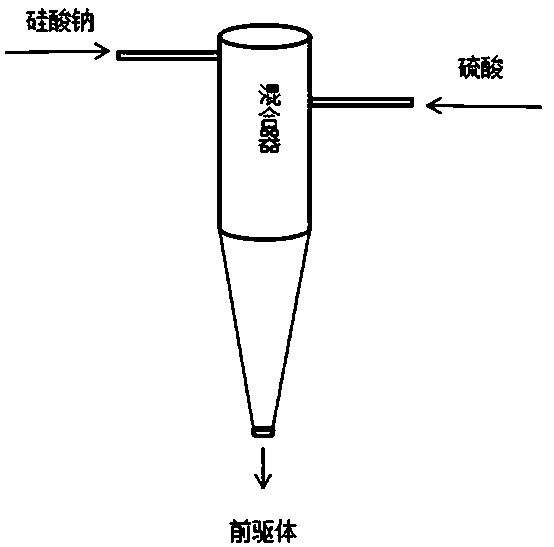

[0021] (2) Precursor synthesis: Add water to sodium silicate to prepare a 4wt% aqueous solution, and add water to sulfuric acid to prepare a 30wt% aqueous solution. At 30°C, at 2.5kg / cm 2 Add the sodium silicate solution into the funnel-shaped acid-base high-efficiency mixer 1 at a speed of 300mL / min under a certain pressure, and at the same time add sulfuric acid solution to control the pH8. The outlet diameter of the device is limited to 10mm;

[0022] (3) Synthesis...

Embodiment 2

[0027] A method for preparing precipitated silica by a continuous method, comprising the steps of:

[0028] (1) Preparation of seed crystals: Prepare 10kg of 4wt% sodium silicate aqueous solution, pass through cation exchange resin, control the pH of the silicic acid solution at the ion exchange outlet to 4.5, and then use sodium silicate to adjust the pH of the silicic acid solution after exchange to 9.4 , add to the reaction tank and raise the temperature to 83°C, keep it warm for 30min, and set it aside;

[0029] (2) Precursor synthesis: Add water to sodium silicate to prepare a 5wt% aqueous solution, and add water to sulfuric acid to prepare a 35wt% aqueous solution. 2 Add the sodium silicate solution into the funnel-shaped acid-base high-efficiency mixer 1 at a speed of 250mL / min under a certain pressure, and at the same time add sulfuric acid solution to control the pH8. The outlet diameter of the device is limited to 5mm;

[0030] (3) Synthesis of precipitated silica:...

Embodiment 3

[0035] A method for preparing precipitated silica by a continuous method, comprising the steps of:

[0036] (1) Preparation of seed crystals: prepare 10kg of 5wt% sodium silicate aqueous solution, pass through cation exchange resin, control the pH of the silicic acid solution at the ion exchange outlet to 4.2, and then use sodium silicate to adjust the pH of the silicic acid solution after exchange to 9.5 , add to the reaction tank and raise the temperature to 90°C, keep it warm for 40min, and set it aside;

[0037] (2) Precursor synthesis: Add water to sodium silicate to prepare a 6wt% aqueous solution, and add water to sulfuric acid to prepare a 40wt% aqueous solution. At 30°C, at 2.5kg / cm 2 Under the pressure of 220mL / min, sodium silicate solution is added to the funnel-shaped acid-base high-efficiency mixer 1, and sulfuric acid aqueous solution is added at the same time to control the pH at the outlet of the funnel-shaped acid-base high-efficiency mixer 1. The funnel-shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com