A kind of porous structure lithium titanate and its preparation method and application

A technology of structural lithium titanate and porous structure, which is applied in the preparation of environmental protection materials and energy fields, can solve the problems of less synthesis reports, etc., and achieve the effects of easy control of process parameters, increased specific surface area, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

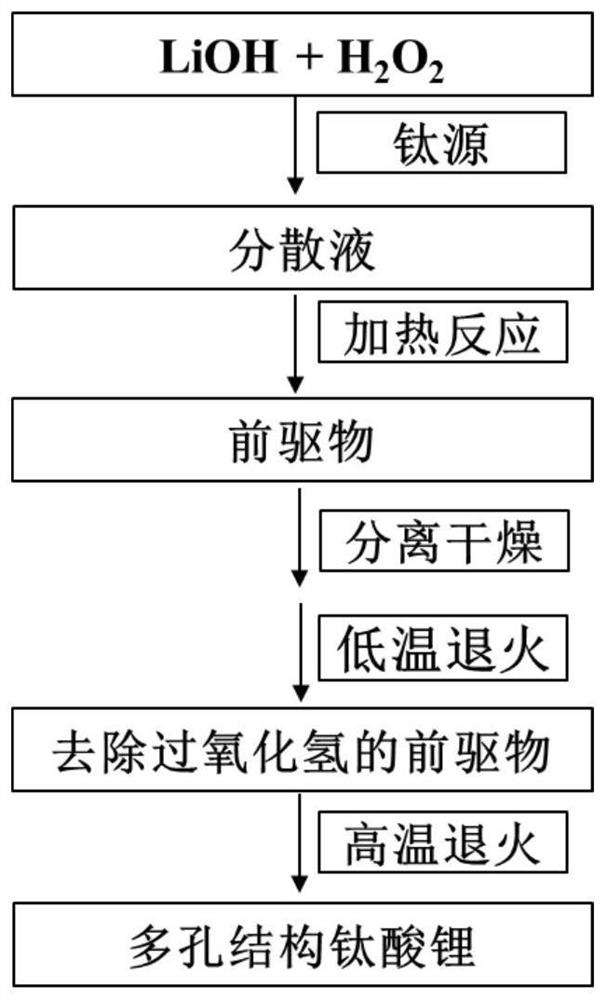

[0072]according tofigure 1 In the process, firstly, hydrogen peroxide and lithium hydroxide are dissolved in water to form an aqueous solution with a lithium hydroxide concentration of 0.6 mole per liter and a hydrogen peroxide volume fraction of 2%. Under stirring conditions, slowly add 2 g of tetrabutyl titanate to the above 100 ml aqueous solution, and stir to form a yellow transparent solution. Subsequently, the yellow transparent solution was heated to 70 degrees Celsius and stirred at constant temperature for 6 hours to stop the reaction to obtain a white solid. Subsequently, the white solid was separated by centrifugation, the moisture content of the separated solid was about 58%, and then it was put into an oven and vacuumed at 60 degrees Celsius for drying. Subsequently, the above-mentioned dried sample was placed in an oven at 200 degrees Celsius for thermostatic treatment for 20 hours to completely remove the hydrogen peroxide adsorbed and contained in the white solid. Su...

Embodiment 2

[0074]First, hydrogen peroxide and lithium hydroxide are dissolved in water to form an aqueous solution with a lithium hydroxide concentration of 0.45 moles per liter and a hydrogen peroxide volume fraction of 1%. Under stirring conditions, slowly add 0.2 g of titanium sulfate to the above 100 ml aqueous solution, and stir to form a yellow transparent solution. Subsequently, the yellow transparent solution was heated to 60 degrees Celsius and stirred at constant temperature for 24 hours to stop the reaction to obtain a white solid. Subsequently, the white solid was separated by filtration, the moisture content of the separated solid was about 55%, and then it was put in an oven and vacuumed at 50 degrees Celsius for drying. Subsequently, the above-mentioned dried white solid was placed in an oven at 150 degrees Celsius for constant temperature annealing for 24 hours to completely remove the hydrogen peroxide adsorbed and contained in the white solid. Subsequently, the white solid fr...

Embodiment 3

[0076]First, hydrogen peroxide and lithium hydroxide are dissolved in water to form an aqueous solution with a lithium hydroxide concentration of 0.8 mole per liter and a 5% hydrogen peroxide volume fraction. Under stirring conditions, slowly add 5 g of titanium isopropoxide to the above 100 ml aqueous solution, and stir to form a yellow transparent solution. Subsequently, the yellow transparent solution was heated to 98 degrees Celsius and stirred at constant temperature for 2 hours to stop the reaction to obtain a white solid. Subsequently, the white solid is separated by suction filtration, and the separated solid has a water content of about 50%, and then it is placed in an oven and vacuum dried at 70 degrees Celsius. Subsequently, the dried white solid was placed in an oven at 250 degrees Celsius for constant temperature annealing for 2 hours to completely remove the hydrogen peroxide adsorbed and contained in the white solid. Subsequently, the white solid from which hydrogen p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com