High-strength steel bar and ultrahigh-performance concrete slab for reinforcing bending member

A high-strength steel, ultra-high-performance technology, used in building construction, building maintenance, ceramic molding machines, etc., can solve problems such as concrete durability problems, structural appearance and clearance effects, and limited bearing capacity improvement. Superior, low cost, no environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

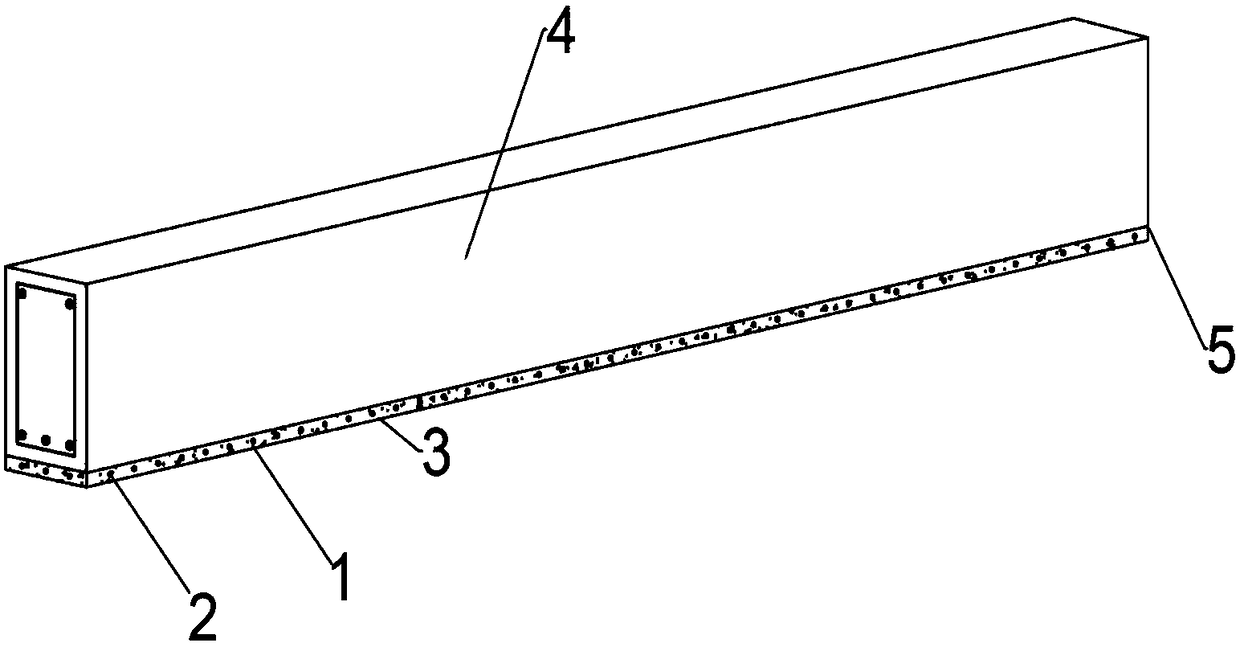

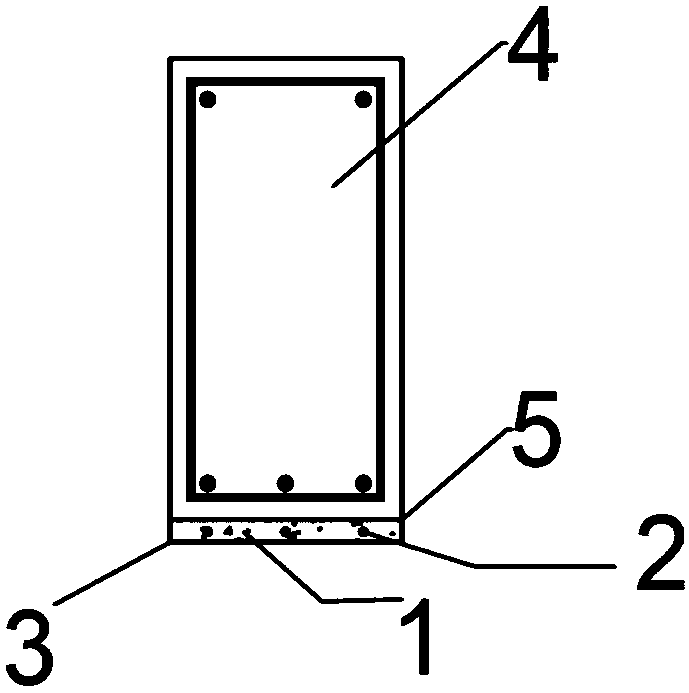

[0019] The present invention will be further described in detail below in conjunction with specific implementation methods and accompanying drawings.

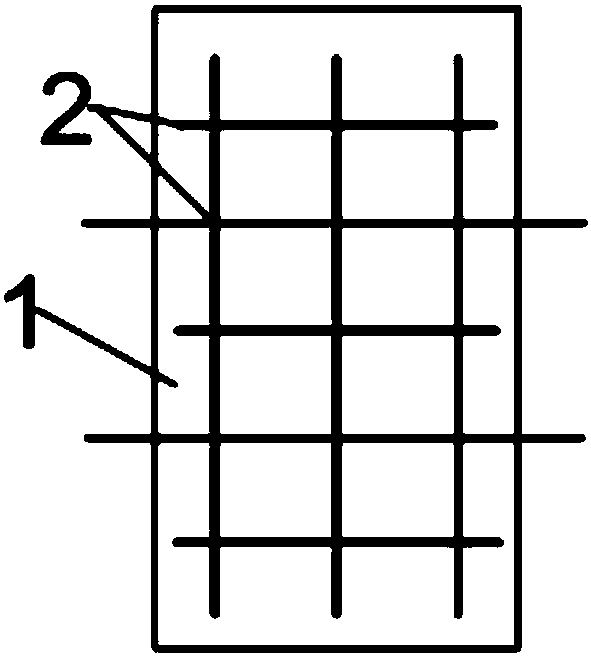

[0020] The first step is to apply prestress to the high-strength steel bar 2, anchor the two ends of the high-strength steel bar 2 on the tensioning device, perform tensioning, and ensure that the surface of the high-strength steel bar 2 is straight, and stop tensioning after reaching the prestress control value and keep prestressed.

[0021] The second step is pouring ultra-high performance concrete 1 with a thickness of 20mm-30mm and curing.

[0022] Step 3: After the concrete 1 reaches the required strength, the concrete 1 and the steel bar 2 have sufficient cohesive force, and then the tension is released to transfer the prestress to the concrete 1 through the cohesive force, check whether the steel bar 2 is flat, and check the formed composite The size of the plate is corrected.

[0023] The fourth step is to clean the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com