High performance liquid chromatography method for 3-nitrophthalic acid

A nitrophthalic acid, high performance liquid chromatography technology, applied in the field of high performance liquid chromatography analysis, can solve the problems of weak column retention, long running time, inability to be separated, etc., and achieve accurate and reliable results and easy operation. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The high performance liquid chromatography analysis method of 3-nitrophthalic acid comprises the following steps:

[0022] 1) 3-nitro-2-methylbenzoic acid is made into a sample solution whose concentration is 0.4g / L;

[0023] 2) Inject 20 μL of the sample solution into the liquid chromatograph;

[0024] 3) Using a C18 chromatographic column with a solution composed of methanol and phosphoric acid as the mobile phase, the volume ratio of methanol and phosphoric acid is 6:4, the flow rate is 1.2mL / min, the detection wavelength is 254nm, and the sensitivity is 0.2aufs;

[0025] The concentration of phosphoric acid is 0.1mol / L, and the pH is 2.8.

[0026] The column temperature of the C18 chromatographic column is 30° C., the C18 chromatographic column is a Kromnsil C18 chromatographic column, the column size of the Kromnsil C18 chromatographic column is 150 mm×4.6 mm, and the particle size in the Kromnsil C18 chromatographic column is 5 μm.

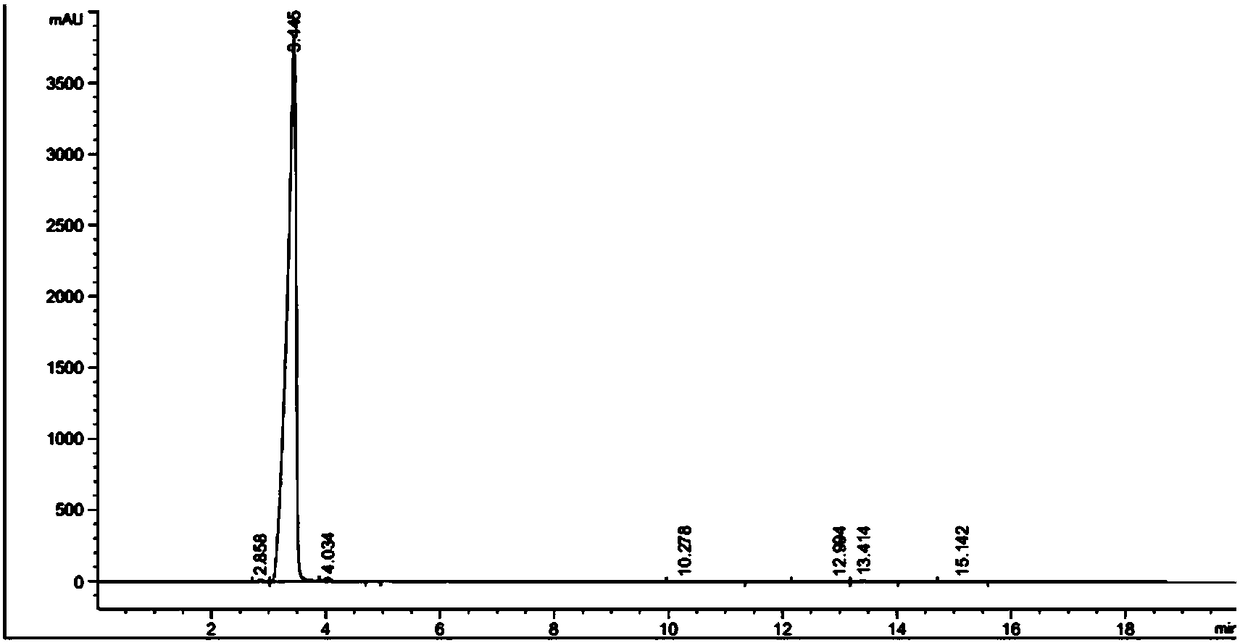

[0027] Such as figure 1 As ...

Embodiment 2

[0029] The high performance liquid chromatography analysis method of 3-nitrophthalic acid comprises the following steps:

[0030] 1) 3-nitro-2-methylbenzoic acid is made into a sample solution whose concentration is 0.4g / L;

[0031] 2) Inject 20 μL of the sample solution into the liquid chromatograph;

[0032] 3) Using C18 chromatographic column, using methanol and sulfuric acid solution as the mobile phase, the volume ratio of methanol and sulfuric acid is 6:4, the flow rate is 1.0mL / min, the detection wavelength is 254nm, and the sensitivity is 0.2aufs;

[0033] Wherein the concentration of sulfuric acid is 0.1mol / L, and the pH is 2.8.

[0034] The column temperature of the C18 chromatographic column is 30° C., the C18 chromatographic column is a Kromnsil C18 chromatographic column, the column size of the Kromnsil C18 chromatographic column is 150 mm×4.6 mm, and the particle size in the Kromnsil C18 chromatographic column is 5 μm.

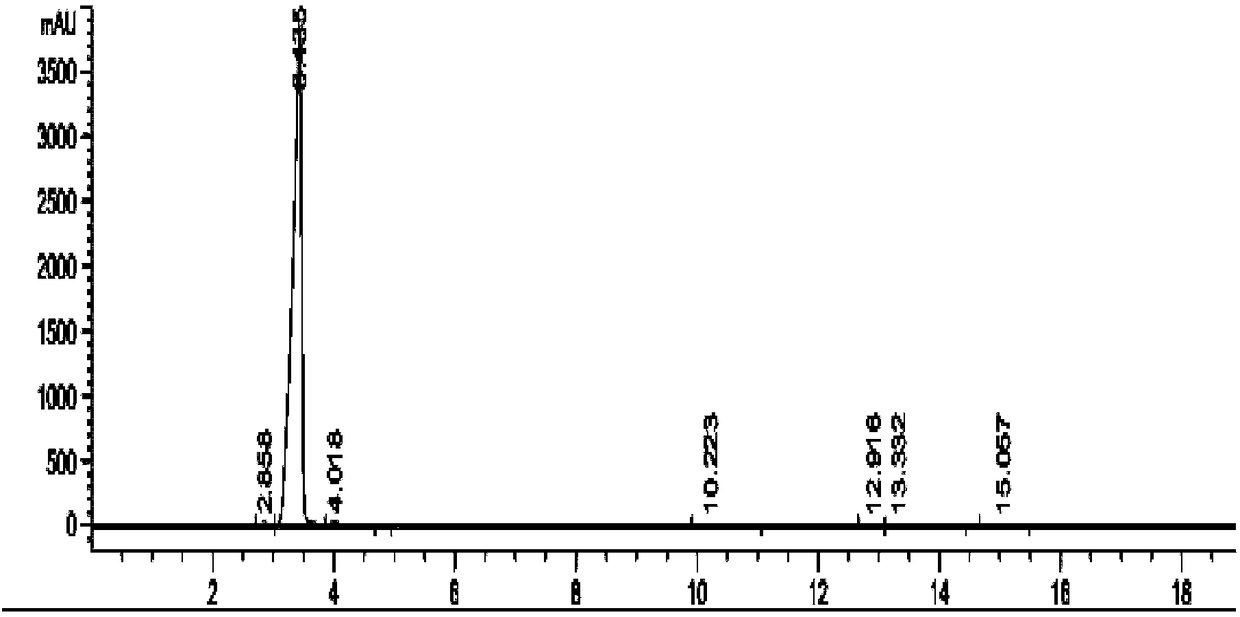

[0035] Such as figure 2 As shown, it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com