Deviation surge absorbing structure built in contact switch

A surge absorbing and switching technology, which is applied in the field of offset surge absorbing structure, can solve the problems of flashover, the total height cannot be lowered between electrodes, and the high voltage cannot be completely insulated and covered, so as to reduce the height and improve the total height. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

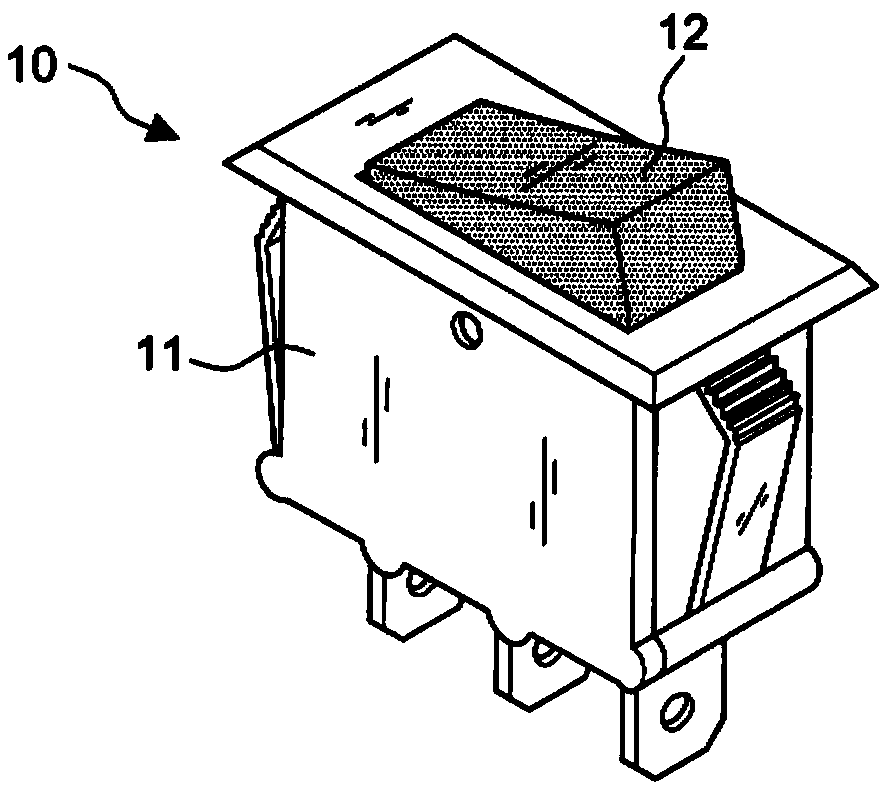

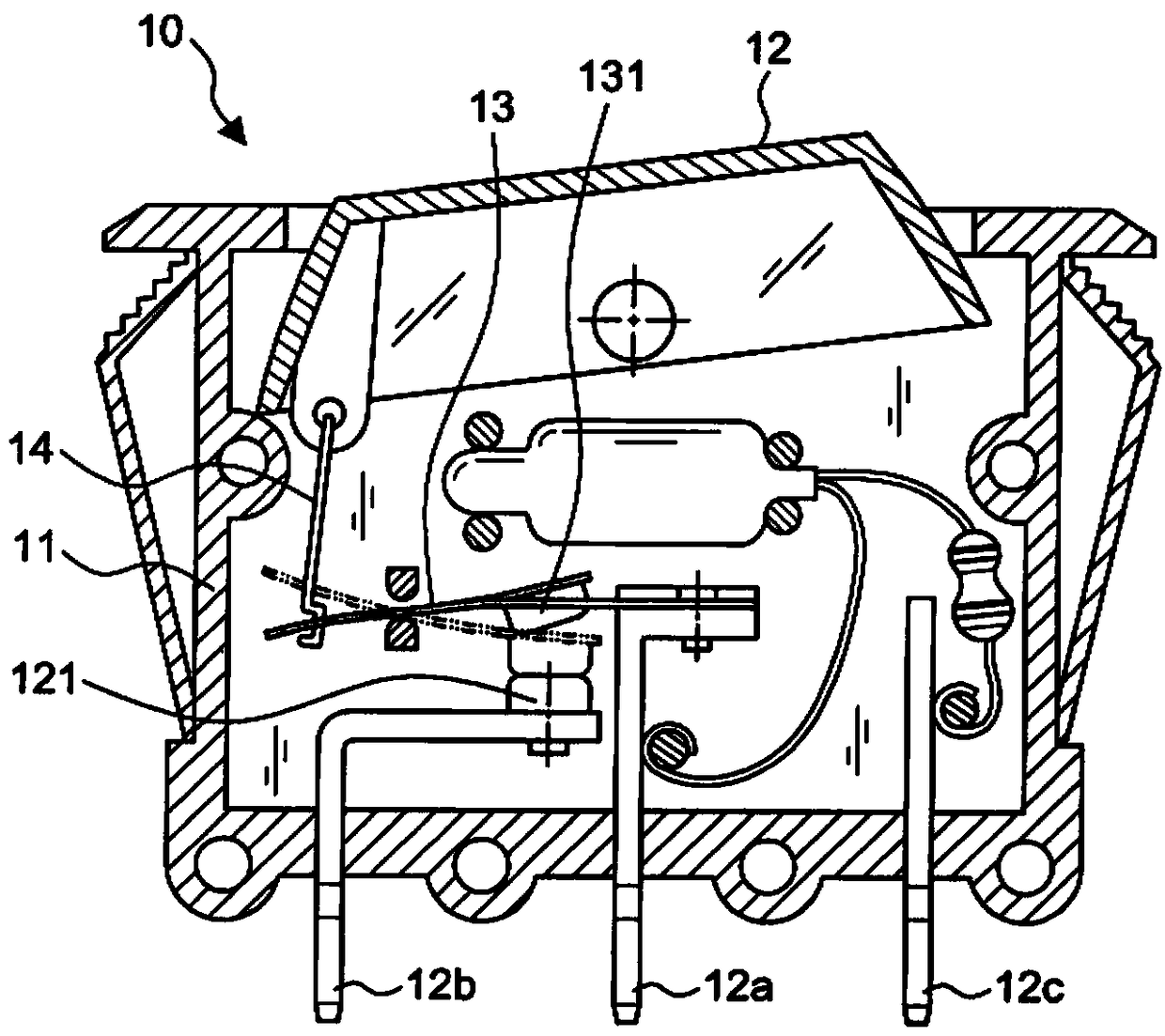

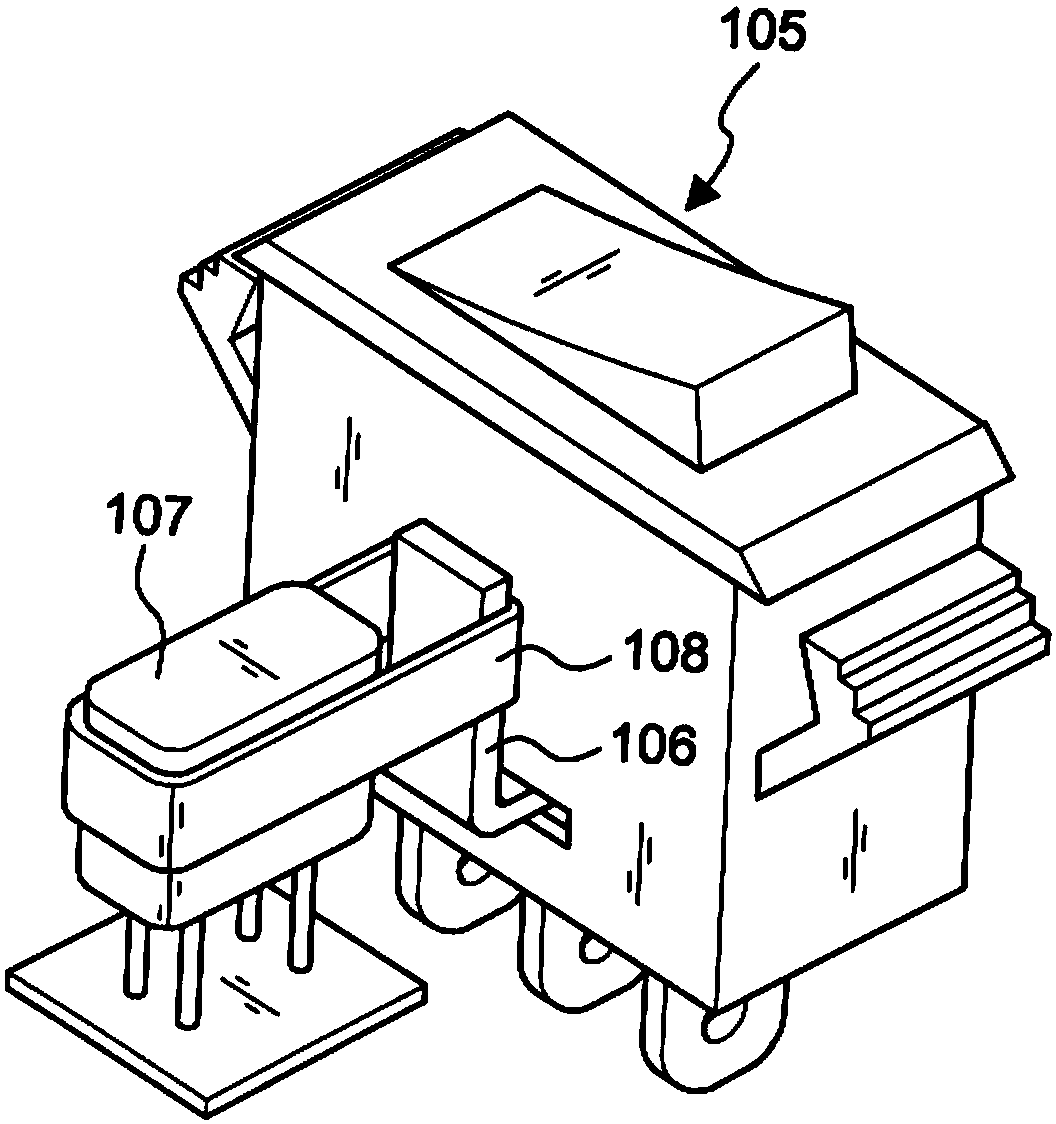

[0111] First, please refer to Figure 3~ Figure 11 As shown, a preferred embodiment of the present invention includes: a contact switch 30. The contact switch 30 disclosed below in the present invention is described with the contact switch module previously disclosed by the inventor, but not It is limited to the following structures, and any switch module with a contact function can be implemented. It includes: a shell 31, a pressing block 32 is arranged at the upper end, and a first lug 40 used as the input of the phase line (L) pole, and a second lug 40 used as the output of the phase line (L) pole are arranged at the bottom end. Wiring piece 50, and a 3rd wiring piece 60 as neutral wire (N) pole input, wherein this first wiring piece 40 is connected with a double metal sheet 41, is provided with a contact reed 42 and in the middle of this double pair metal sheet 41 A first contact point 421, the lower portion 51 of the second lug 50, relative to the position of the first c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com