Pellet production apparatus and pellet production method

A particle manufacturing and spraying device technology, which is applied in the field of thermoplastic resin particle manufacturing devices, can solve problems such as yield reduction, achieve the effect of improving quality and suppressing the generation of continuous particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0081] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited thereto.

[0082] (Pellet manufacturing device)

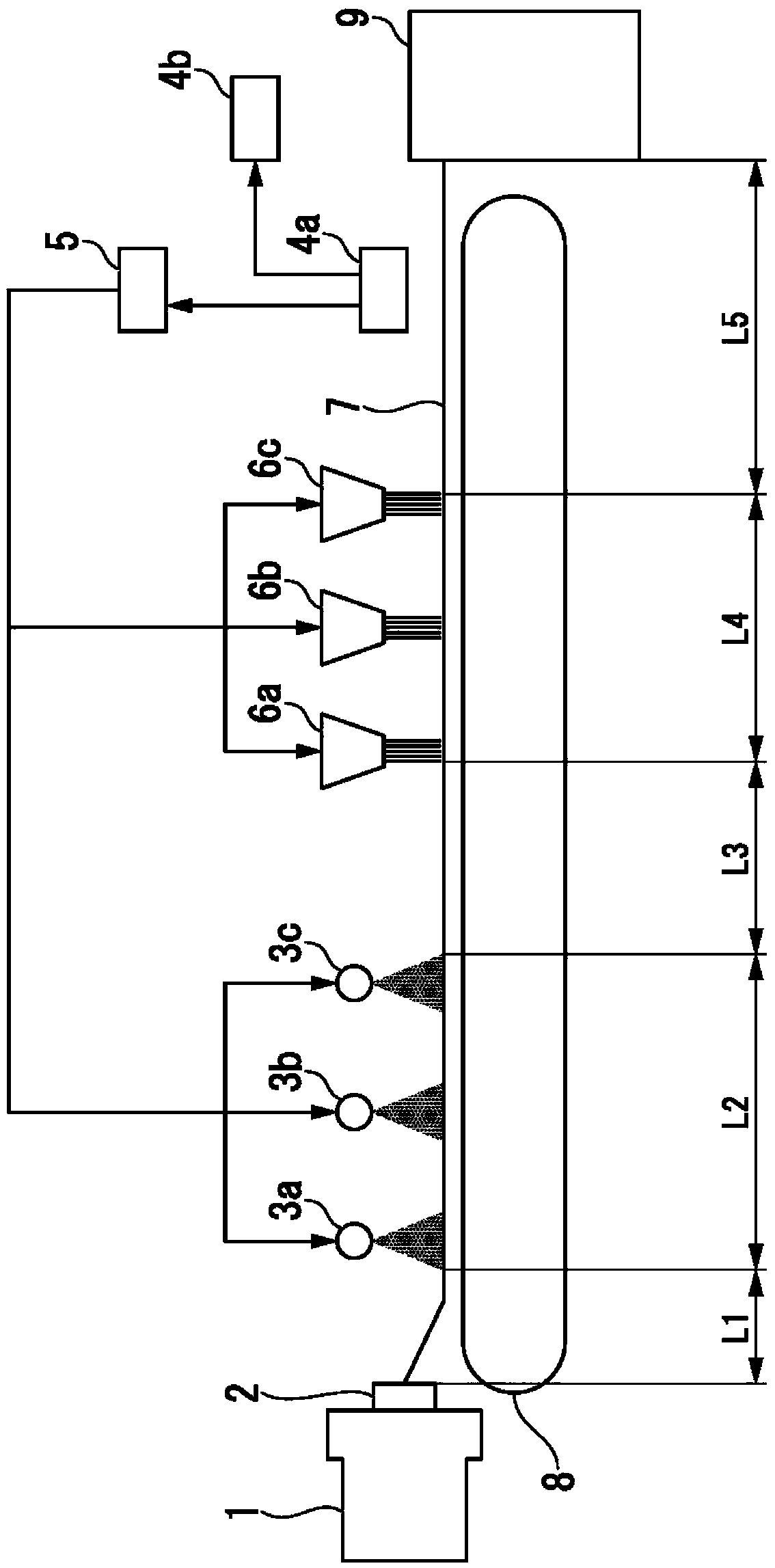

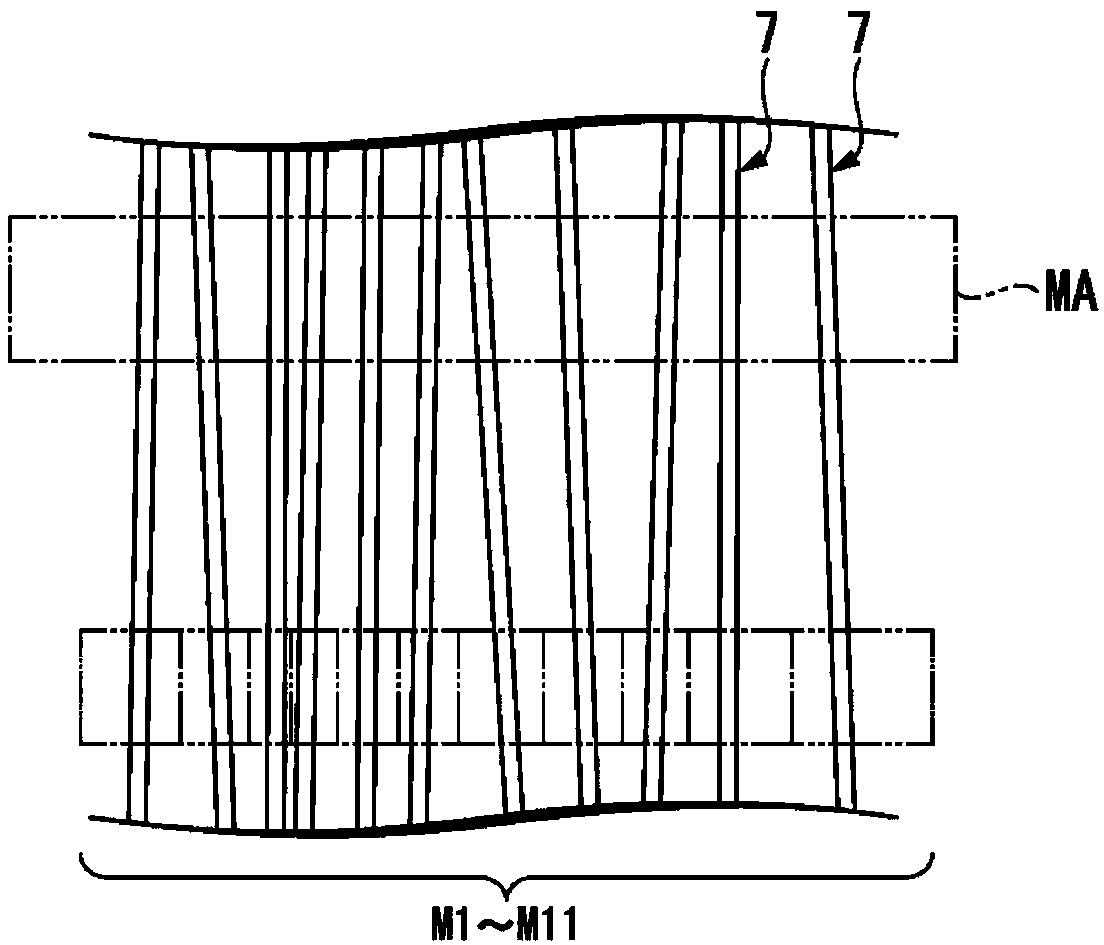

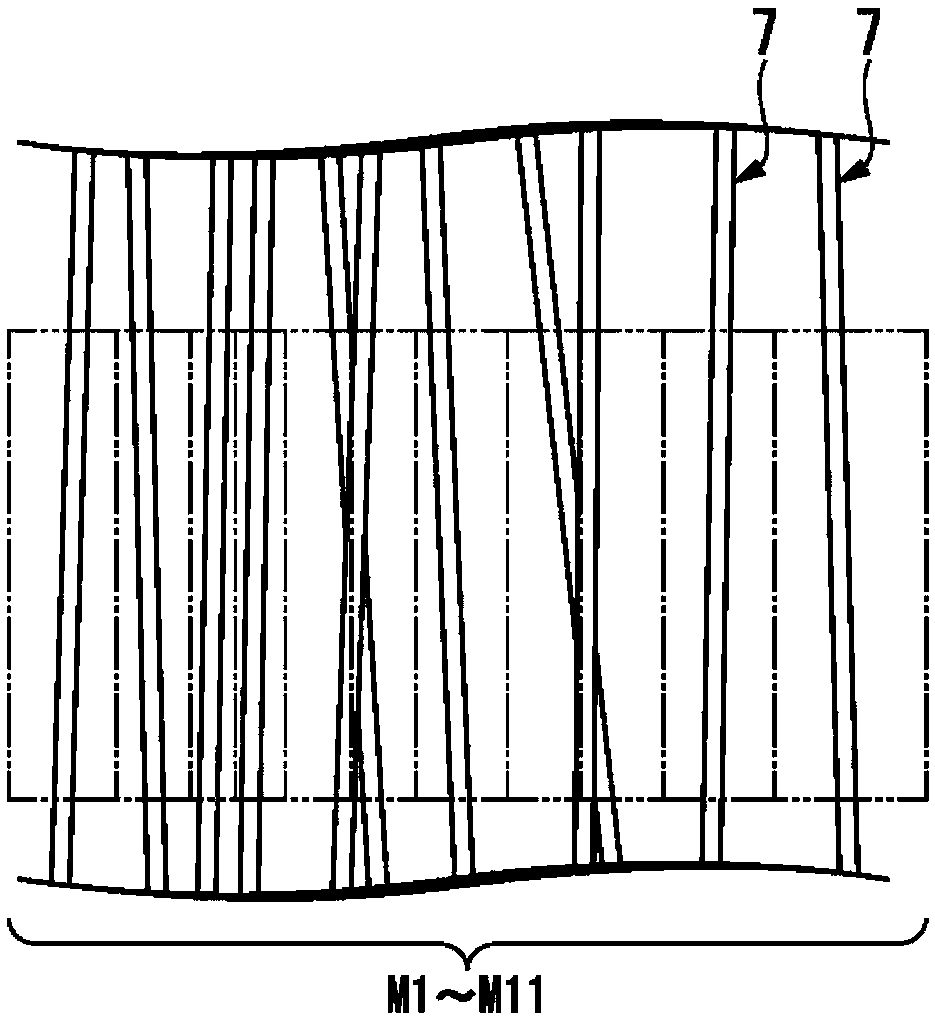

[0083] use figure 1 The manufacturing apparatus used in the examples of the present invention will be described. First, a discharge port 2 was attached to the front end of a feeder 1 for melting a thermoplastic resin (twin-screw extruder "TEM-26" manufactured by Toshiba Machine Co., Ltd.) so as to discharge 15 strands. Then, set the conveyor belt 8 for conveying the discharged strands (the contact surface with the strands is a herringbone twill stainless steel mesh), on the top of the conveyor belt conveying surface, at equal intervals along the conveying direction of the conveyor belt and at a height of 170 mm from the conveyor belt Configure three liquid spray devices 3a to 3c for cooling the strands conveyed by the conveyor belt, and then arrange three gas blowing devices 6a to 6c at equal...

Embodiment 1

[0102] According to the ratio shown in Table 2, (A1) polyethylene terephthalate ("MA-2103" manufactured by UNITIKA Co., Ltd., melting point 255 ° C, Tg 70 ° C) and (B1) calcium carbonate (Maruo Calcium Co., Ltd. "CALTEX 5" (powder, average particle size: 1.2 μm)) was dry-mixed, and then the raw materials were supplied and melt-kneaded under the conditions shown in Table 2 using a twin-screw extruder, and then, use figure 1 The particle production apparatus shown performs the production of particles. That is, a plurality of strands (strand diameter: 3 mm) were discharged from the discharge port of the melt-kneading device. While conveying 15 strands on a conveyor belt at a rate of 50 m / min, the atmosphere temperature of the conveyor belt was kept at room temperature (23° C.) for 3 hours and continuous production was performed to produce pellets.

[0103] Such as figure 1 As shown, the measuring device 4 a is disposed between the gas blowing device 6 c and the strand cutter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com