Highly transparent chemical-resistant blow-molded laminate container leaching few impurity particles

A technology of chemical resistance and blow molding, which is applied in chemical instruments and methods, household containers, types of packaging items, etc., and can solve problems such as unreachable cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

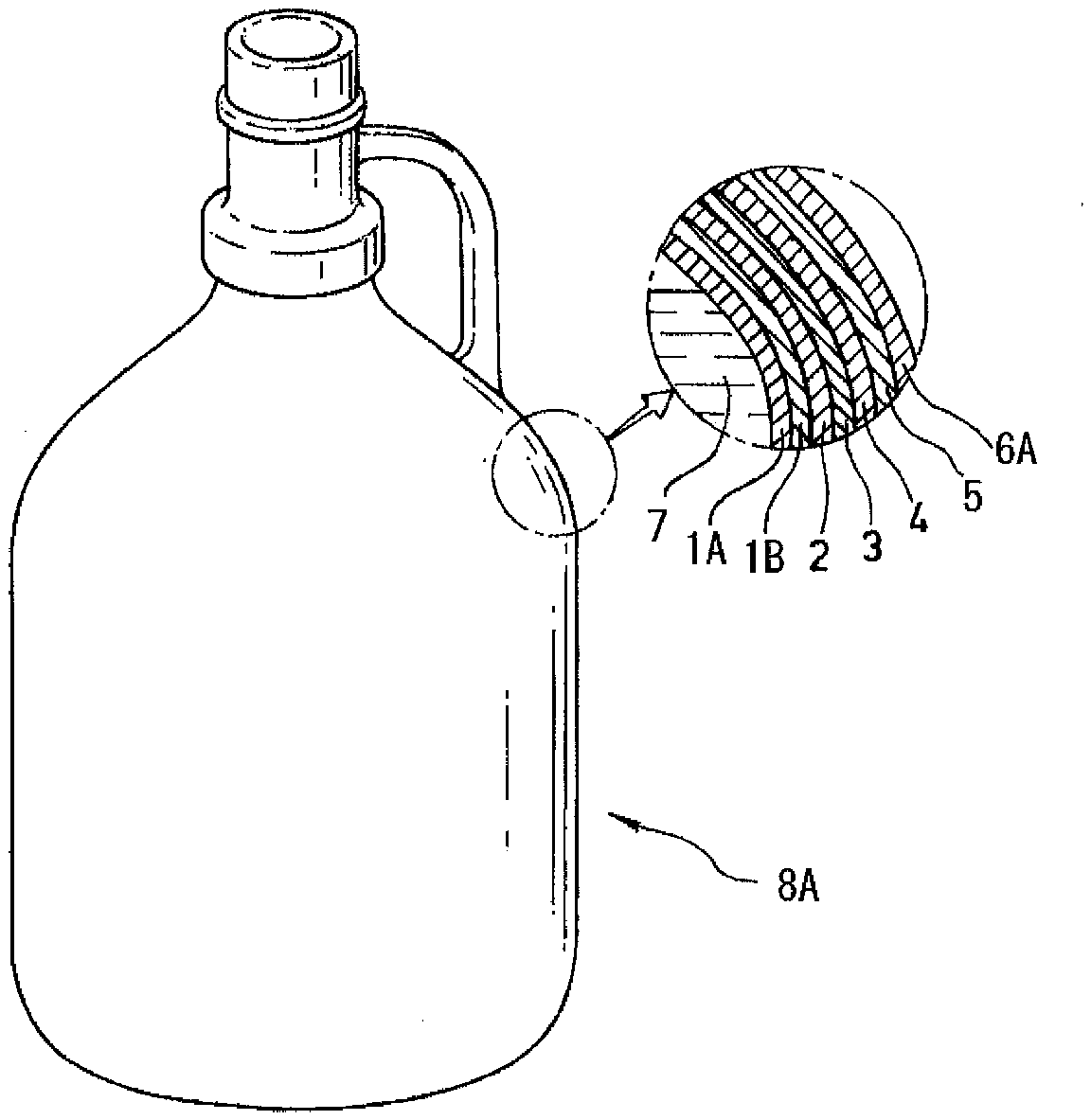

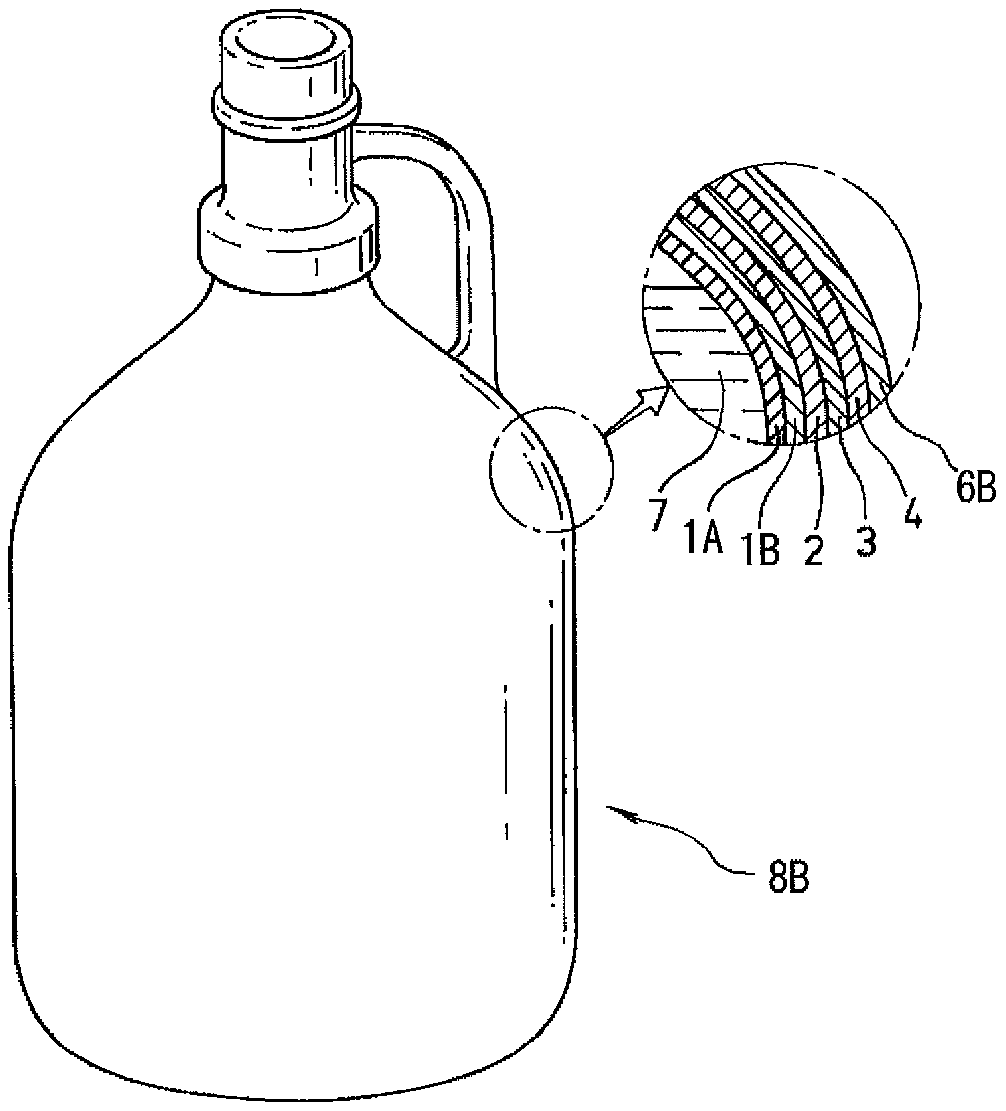

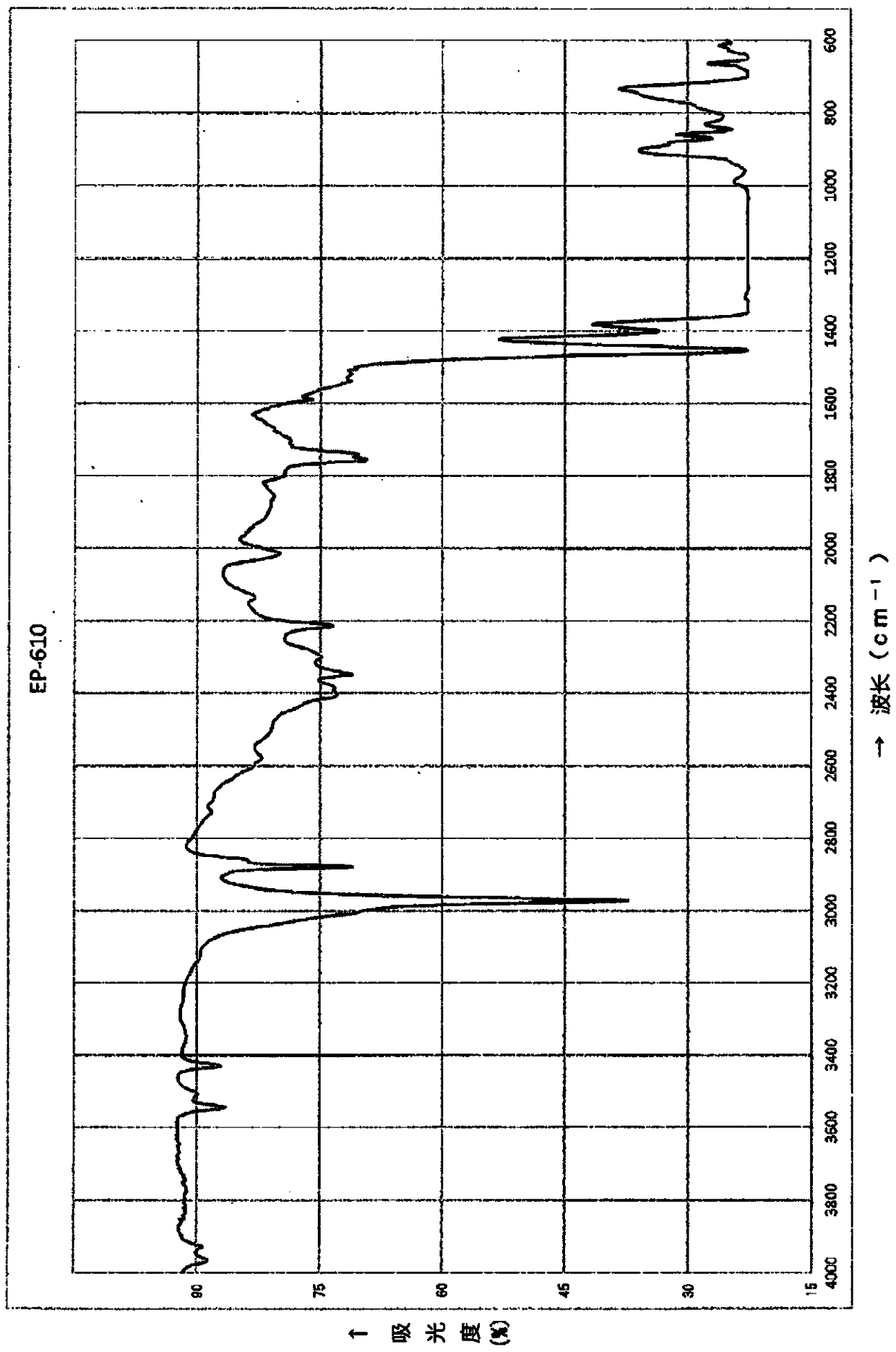

[0212] MFR is 25g / 10min, specific gravity is 1.86, melting point is 223 ℃, and heating loss is 0.16 mass % additive-free fluororesin (EP-610 manufactured by DAIKIN INDUSTRIES, LTD.) as inner layer 1, and MFR is 25g / As the inner layer 2, an additive-free fluororesin (RP-5000 manufactured by DAIKIN INDUSTRIES, LTD.) with a specific gravity of 1.74, a melting point of 195° C., and a heating loss of 0.35% by mass was used as the inner layer 2. Additive-free polyamide resin (Z4887 manufactured by Daicel-Evonik Ltd., relative viscosity: 1.87) that does not contain intentionally added additives or additives containing lubricants is used as the barrier and adhesive resin layer, and maleic anhydride is used. A modified polyolefin resin (FT71A of Japan Polyethylene Corporation) was used as an adhesive layer having a function of bonding the polyamide resin to the barrier layer, and a barrier resin (ethylene-vinyl alcohol copolymer resin F171B: KURARAY CO., LTD, saponification rate 99.99...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com