Cut tobacco recycling device for waste cigarettes

A shredded tobacco recovery device and technology for waste cigarettes, which can be used in swirling devices, tobacco, and cigarette manufacturing, etc., can solve the problems of shredded tobacco waste, uncompact overall structure, and unreasonable design, so as to reduce the loss of flavor and moisture, and facilitate the production of cigarettes. Mobile and online use, the overall structure is reasonable and compact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention relates to a shredded tobacco recovery device for waste cigarettes, which is mainly used in the cigarette manufacturing process to recycle shredded tobacco in waste cigarettes online. The invention will be further described below in conjunction with the accompanying drawings:

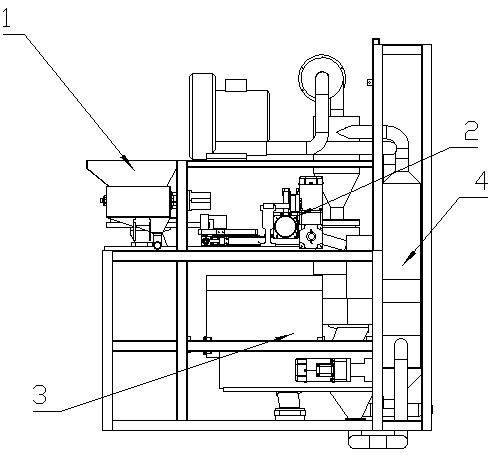

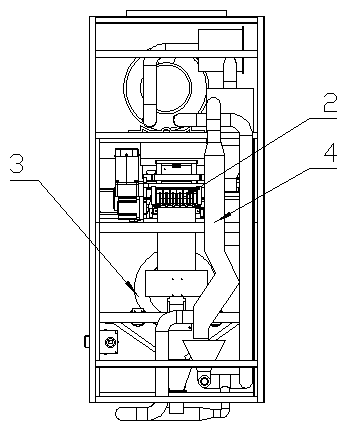

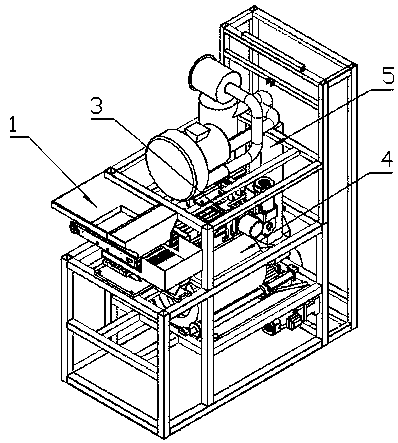

[0031] Such as Figure 1-3 Shown is the overall structure diagram of a waste cigarette shredded tobacco recovery device protected by the present invention. It mainly includes: a cigarette straightening device 1 , a cigarette cutting device 2 , a shredded tobacco-dirty separation device 3 and a shredded tobacco purification device 4 .

[0032] Its basic working principle is: the incoming waste cigarettes are separated from the mixed shredded tobacco in the cigarette straightening device 1, and the cigarettes are straightened and then sent to the cigarette cutting device, and passed through the cigarette cutting device 2. Positioning, rolling, and complete cutting, and then t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com