Drilling tire tooling device for locking wire holes of screw for large canned motor

A technology for shielding motors and locking holes, applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve problems such as scrapped workpieces, deviation of locking holes, and large locking holes, etc., to reduce tool damage and ensure Machining accuracy, the effect of ensuring practical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

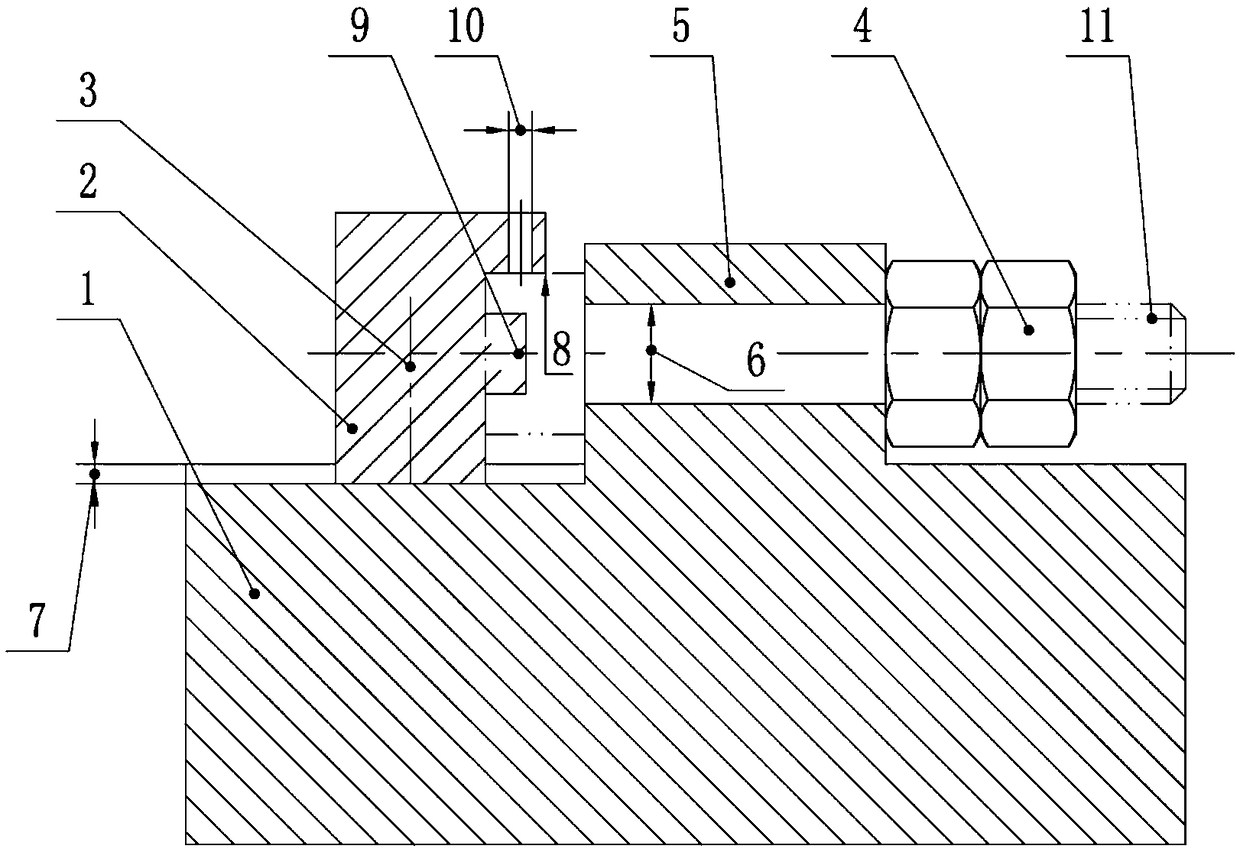

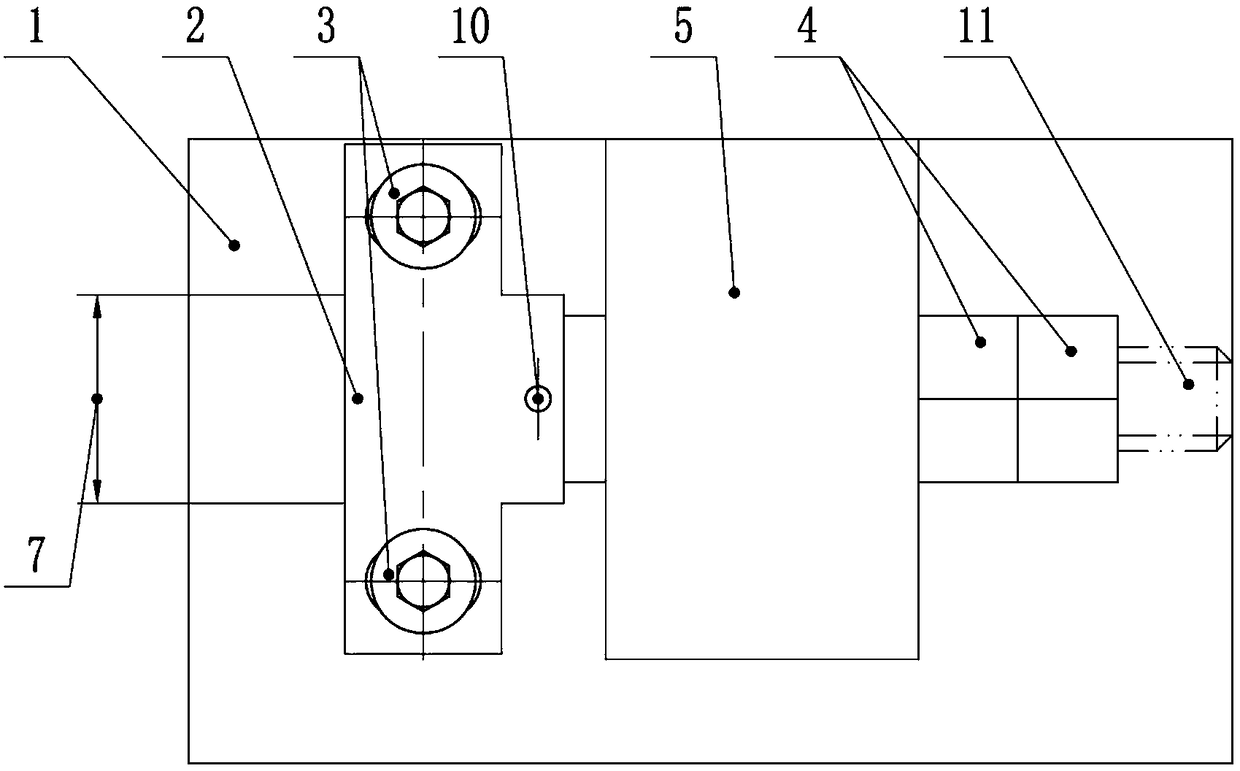

[0014] Such as figure 1 As shown, a shielded motor screw locking wire hole drilling tooling device is composed of a placenta 1, a limiting device and a fastening device. The limiting device includes a limiting block 2 and a connecting bolt 3; the fastening device is a nut 4, and the tire There is a boss 5 in the center of the seat 1, a circular through hole 6 is processed in the middle of the boss 5, a groove 7 is processed on one side of the boss 5, the limit block 2 and the groove 7 slide freely, and the two sides of the groove 7 Processing is used for the threaded hole that is fitted with connecting bolt 3.

[0015] The limit block 2 is located in the groove 7 of the placenta 1, and the connecting bolt 3 passes through the waist holes on both sides of the limit block 2 and is connected and fixed with the threaded holes on both sides of the groove of the placenta 1; shaped groove 8 and a hexagonal protrusion 9 in the middle of the circular groove 8, the circular groove 8 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com