Layered type gradient pore structure aluminum or aluminum alloy foam and preparation method

A technology of aluminum alloy foam and gradient pores, which is applied in the field of porous metal materials, can solve the problems of difficult preparation of percolation precursors and control of pore structure, high porosity of polyurethane foam, etc., and achieve good sound absorption performance and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

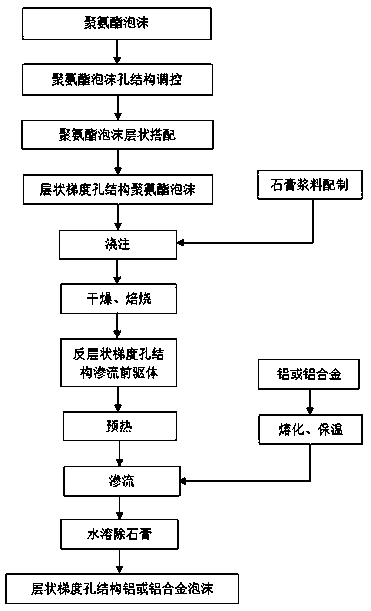

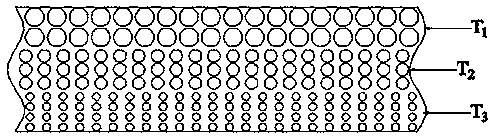

[0051] The preparation method of a three-layer gradient pore structure Al-Si12 alloy foam described in this embodiment, the specific steps are:

[0052] (1) Polyurethane foam pore structure control: Three commercially available polyurethane foams with a pore diameter of 1.2mm and a porosity of 91%, a pore diameter of 1.03mm and a porosity of 89.5%, and a pore diameter of 0.9mm and a porosity of 88% were placed in the mass percentage Immerse in 35% water-soluble polyurethane emulsion for 10 minutes, then take out the polyurethane foam and dry it in a drying oven at 80°C for 25 minutes. The pore size and porosity are regulated, and three kinds of polyurethane foams with a pore size of 0.9mm and a porosity of 85%, a pore size of 0.6mm and a porosity of 81.8%, and a pore size of 0.3mm and a porosity of 79% are obtained in sequence.

[0053] (2) Polyurethane foam layered collocation

[0054] The same thickness of polyurethane foam regulated by the above step (1) through the pore s...

Embodiment 2

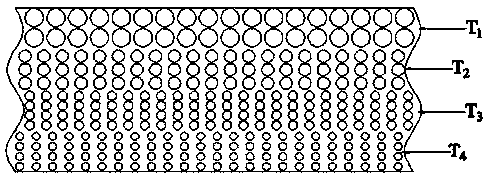

[0060] The preparation method of a four-layer gradient pore structure ZL101 alloy foam described in this embodiment, the specific steps are:

[0061] (1) Polyurethane foam pore structure control: Four types of polyurethane foam with a pore size of 1.2mm and a porosity of 91%, a pore size of 1.0mm and a porosity of 89%, a pore size of 0.93mm and a porosity of 88.5%, and a pore size of 0.9mm and a porosity of 88% are used in sequence. Put the sold polyurethane foam in 35% water-soluble polyurethane emulsion for 15 minutes, then take out the polyurethane foam and dry it in a drying oven at 70°C for 30 minutes. 2, 3, and 4 times, the pore size and porosity of the polyurethane foam are adjusted, and the pore size is 0.9mm, the porosity is 85%, the pore size is 0.7mm, the porosity is 83%, the pore size is 0.5mm, the porosity is 80.8%, and the pore size is 0.3mm. , four kinds of polyurethane foam with a porosity of 79%.

[0062] (2) Polyurethane foam layered collocation

[0063] Th...

Embodiment 3

[0069] The preparation method of a ZL201 alloy foam with a five-layer gradient pore structure described in this embodiment, the specific steps are:

[0070] (1) Polyurethane foam pore structure control: 1.2mm pore size, 91% porosity, 1.1mm pore size, 90% pore size, 1.0mm pore size, 89% pore size, 1.03mm pore size, 89.5% porosity, and 0.93mm pore size. , five kinds of commercially available polyurethane foams with a porosity of 88.5% were placed in a water-soluble polyurethane emulsion with a mass percentage of 35% and immersed for 20 minutes, then the polyurethane foams were taken out and dried at 60°C for 35 minutes in a drying oven, and the above five polyurethane foams were tested in turn. Repeat the dipping process, the total number of times is 2, 2, 2, 3, 3 times, the pore size and porosity of the polyurethane foam are adjusted, and the pore size is 0.9mm, the porosity is 85%, the pore size is 0.8mm, the porosity is 84%, the pore size Five kinds of polyurethane foam with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com