Plasma combustion-supporting exciter with dual working modes of combustion supporting and ignition

A dual working mode, plasma technology, applied in the direction of plasma, engine ignition, machine/engine, etc., can solve the problems of poor ignition reliability, low ignition energy utilization rate, small ignition energy, etc. Ionization and ignition effect, high working pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

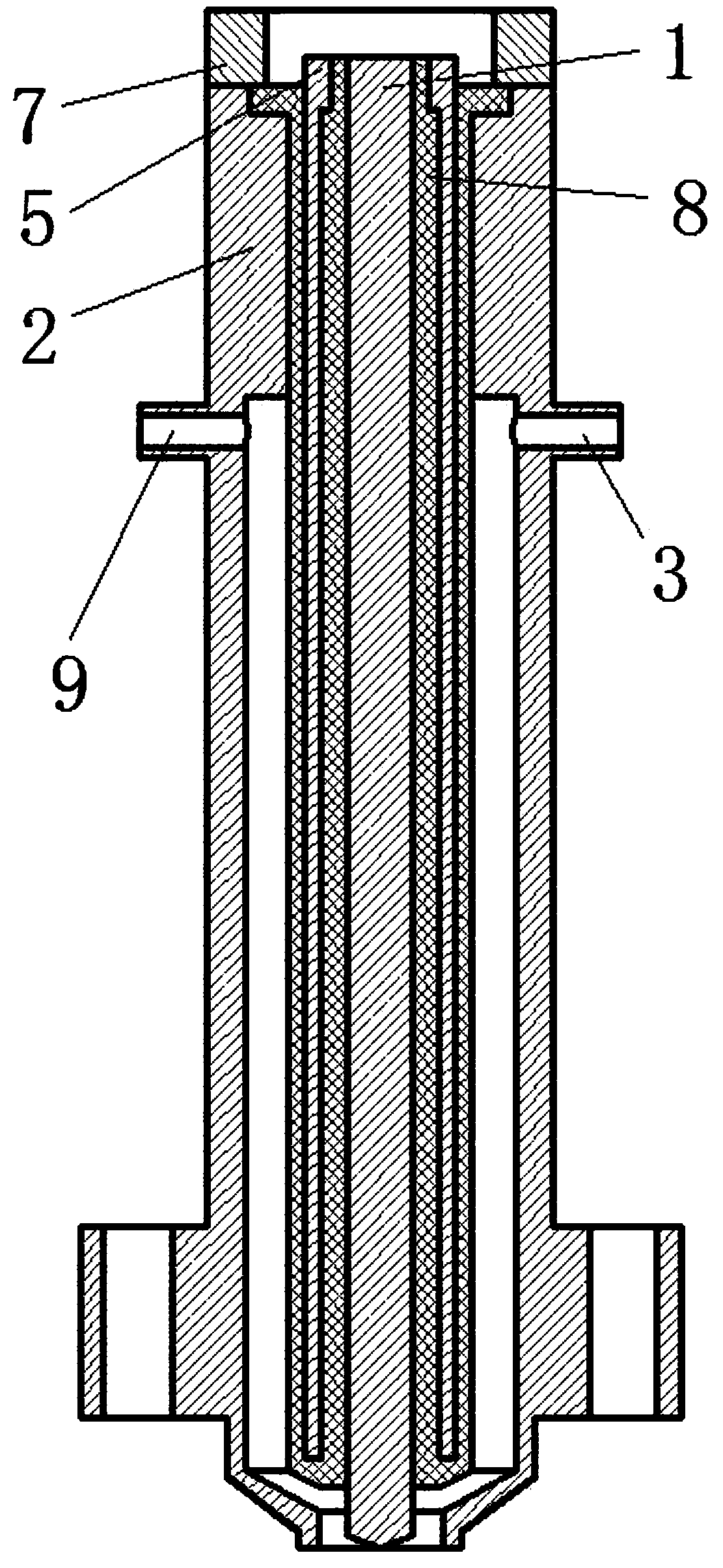

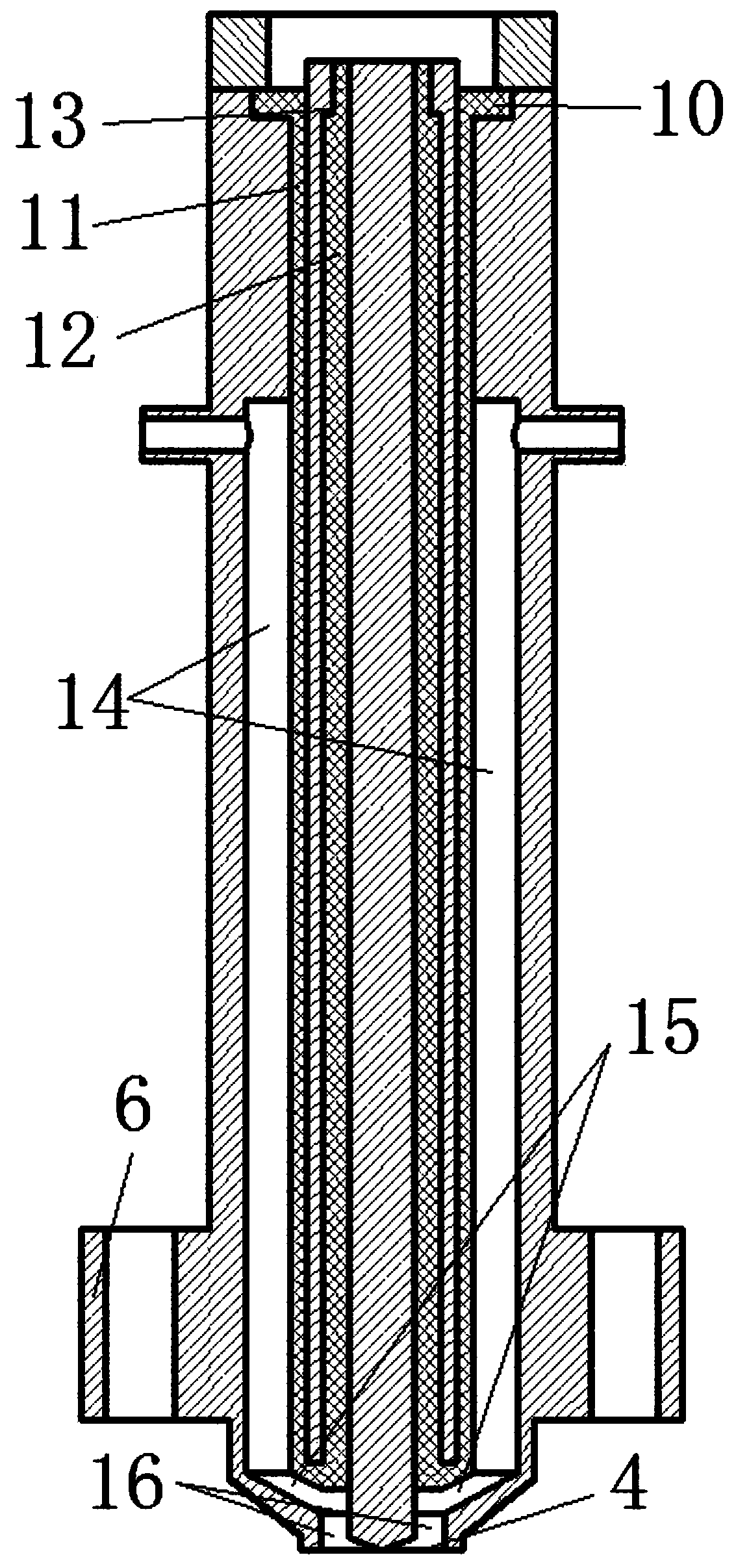

[0021] A plasma combustion-supporting exciter with dual working modes of combustion-supporting and ignition, including a central anode 1, a ground electrode 2, a ring-shaped anode 5 and an insulating positioning sleeve 8; the insulating positioning sleeve 8 has a through hole for installing the central anode 1 and the annular groove for installing the annular anode 5, the upper end of the insulating positioning sleeve 8 has an outwardly protruding mounting platform 10, and the upper end of the grounding electrode 2 has a mounting groove that is connected with the mounting platform 10, and the insulating positioning sleeve 8 is located on the grounding electrode 2 internal.

[0022] The insulating positioning sleeve 8 includes an inner wall 12 and an outer wall 11. The inner wall 12 surrounds and forms a through hole. There is an annular groove between the inner wall 12 and the outer wall 11. The mounting table 10 is located on the top of the outer wall 11. There is a positionin...

Embodiment 2

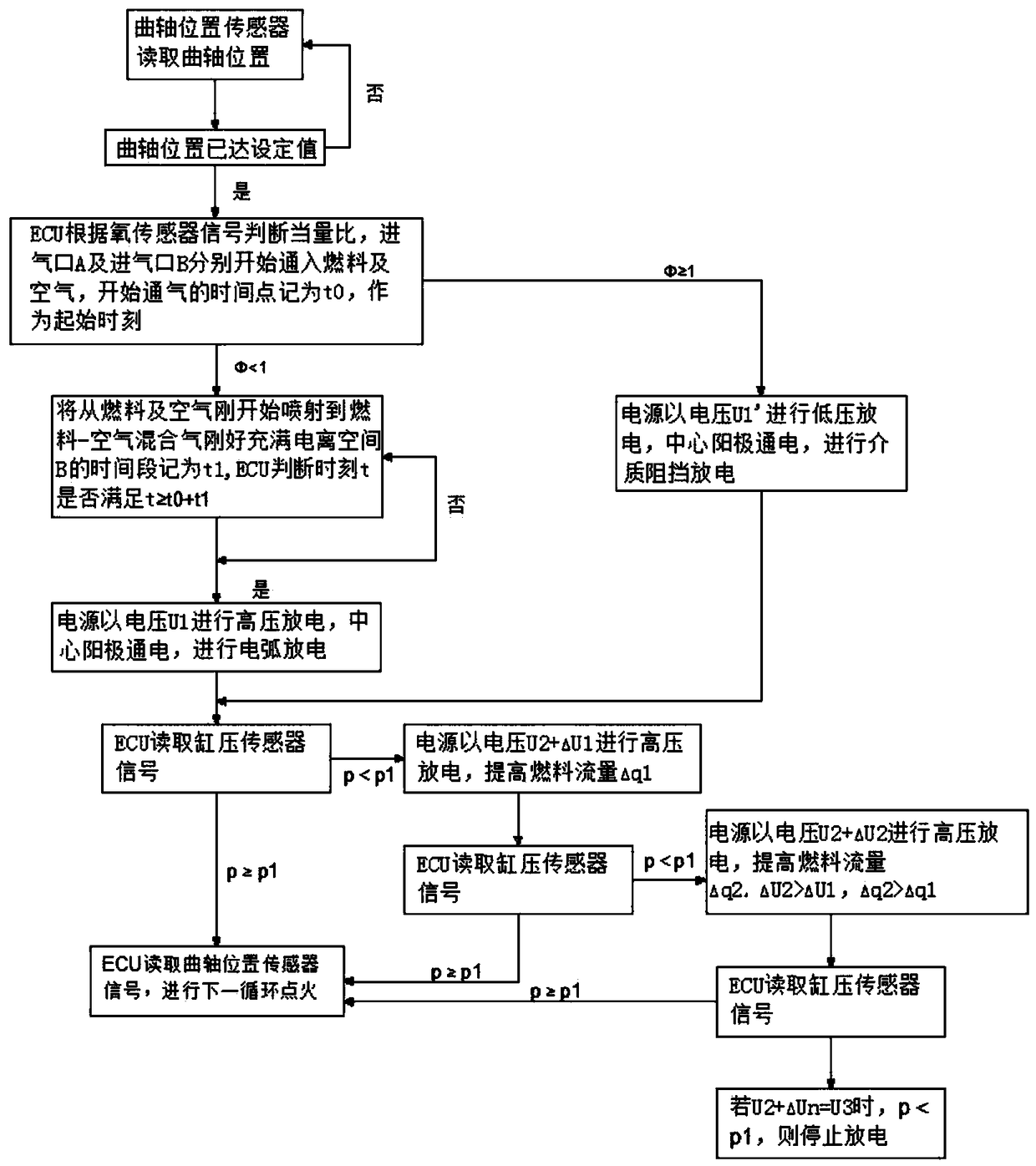

[0034] This embodiment is a control strategy applied to piston engines according to the present invention, especially to piston engines with reciprocating or rotary pistons.

[0035] 1. The crankshaft position sensor judges the crankshaft position. If the current crankshaft angle has not reached the set value, continue to judge. If it has reached the set value, the oxygen sensor judges the equivalent ratio Φ at this time, and the air inlet A9 and the air inlet Fuel and air are fed into B3 respectively, and this time is recorded as time t0; starting from time t0, the time when the fuel-air mixture fills the ionization space B16 for the first time is recorded as time t1.

[0036] 2. If Φ<1, the ECU sends a high-voltage power supply command to the power supply (for example: 15,000-20,000 volts); the power supply supplies high-voltage power to the center electrode 1 at time t1, forming an arc discharge in the ionization space B16, and fuel-air mixing The gas is ignited, and the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com