A shock absorber with extended service life

A shock absorber, life-span technology, used in shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve problems such as reducing the service life of the guide, damage to the guide, and rupture of the limit block of the shock absorber. Achieve the effect of reducing wear and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

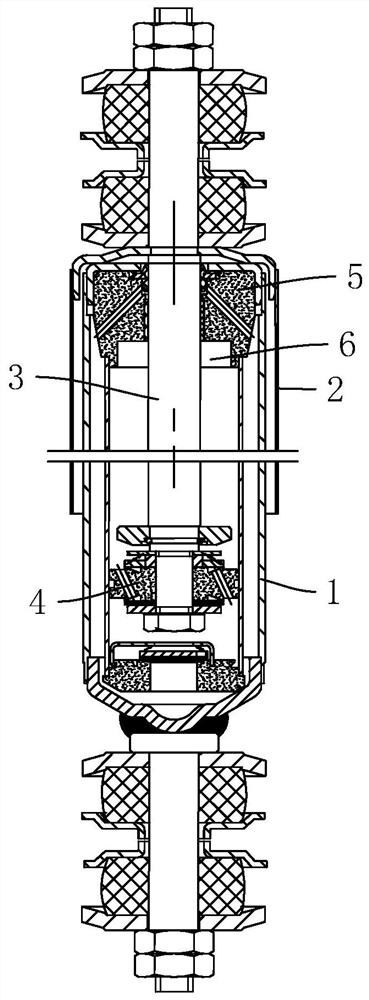

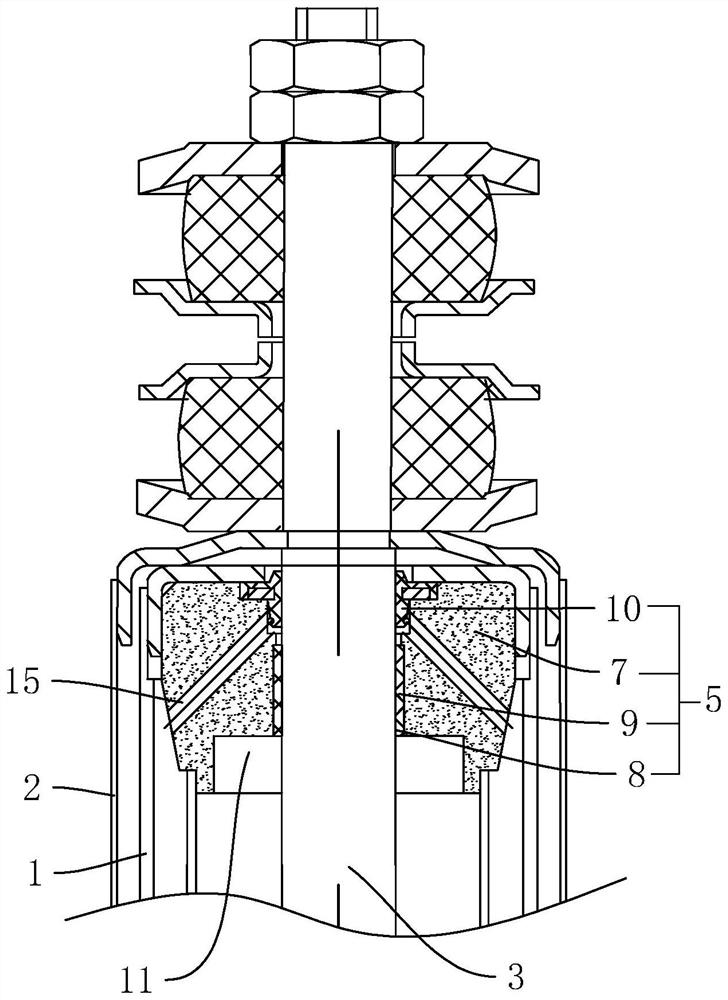

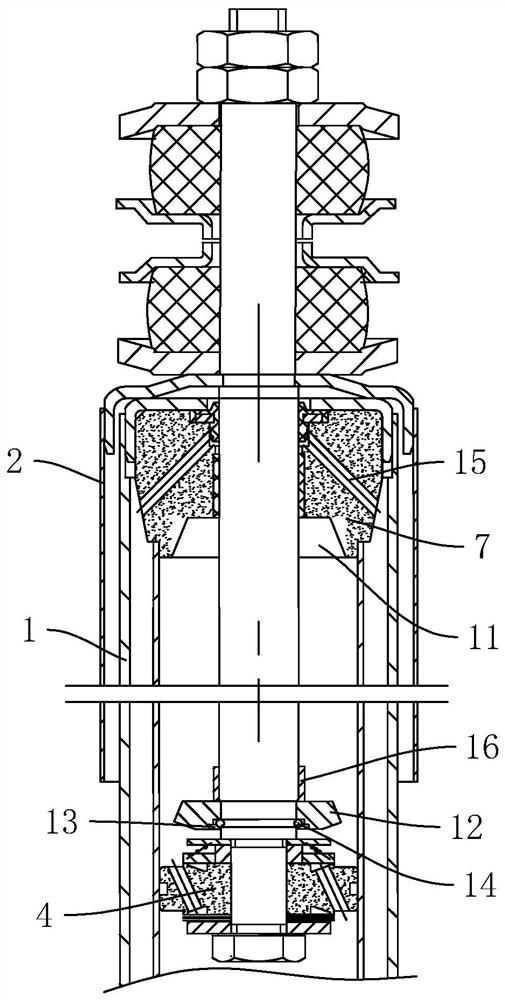

[0034] refer to figure 1 and figure 2, is a shock absorber that can prolong the service life disclosed by the present invention, comprising an oil storage tube 1, a dust cover 2 covering one end of the oil storage tube 1, passing through the end of the oil storage tube 1 and fixedly connected to the The piston rod 3 in the middle of the dust cover 2, the end of the piston rod 3 extending into the oil storage tube 1 is connected to the piston 4, and the oil storage tube 1 is fixed at the end near the dust cover 2 and located inside the oil storage tube 1. The guide assembly 5, the end of the guide assembly 5 facing the piston 4 is provided with a hydraulic limit assembly 6; when the shock absorber is working, the piston rod 3 slides up and down relative to the oil storage cylinder 1, when the piston rod 3 drives the piston 4 toward When the direction of the guide assembly 5 moves close, the piston rod 3 is hydraulically limited by the hydraulic limit assembly 6, avoiding the ...

Embodiment 2

[0040] refer to image 3 , is a shock absorber that can prolong the service life disclosed by the present invention. The difference from Embodiment 1 is that the buffer tank 11 is in the shape of a truncated cone, and the diameter of the buffer tank 11 gradually becomes smaller from the outside to the inside, that is, from close to The diameter of one end of the locking ring 12 gradually decreases toward the end away from the locking ring 12, the shape of the locking ring 12 is adapted to the buffer groove 11, and the gap between the locking ring 12 and the buffer groove 11 is 0.1mm.

[0041] The piston rod 3 drives the locking ring 12 to move toward the guide 7. When the locking ring 12 enters the buffer tank 11, the end of the locking ring 12 with a smaller diameter enters the end of the buffer tank 11 with a larger diameter. At this time, the oil The resistance to the locking ring 12 is small. As the locking ring 12 continues to move, the gap between the side wall of the lo...

Embodiment 3

[0044] refer to Figure 4 , is a shock absorber that can prolong the service life disclosed in the present invention. The difference from Embodiment 1 is that the side wall of the buffer tank 11 is arranged in a stepped shape, and the side wall of the locking ring 12 is in a shape that matches the buffer tank 11. It is arranged in a stepped shape, and the gap between the locking ring 12 and the inner wall of the buffer groove 11 is 0.1mm.

[0045] When the piston rod 3 drives the locking ring 12 to move toward the guide 7, the gap formed between the side wall of the locking ring 12 and the inner wall of the buffer tank 11 is also stepped, and compared with the gap in the first embodiment, the oil flow rate is lower. The resistance is greater, and the stepped shape has a bent part. When the bent part of the locking ring 12 abuts against the bent part of the inner wall of the buffer tank 11, it is easier to form a sealed environment, so that the locking ring 12 and the guide Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com