Rapid evaluation method and rapid evaluation device for wear resistance of coating sample array

An evaluation method and wear resistance technology, applied in the field of materials, can solve the problems of complex process, low efficiency, low efficiency of coating wear resistance optimization, etc., and achieve the effect of small experimental workload, high calculation accuracy and fast measurement speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

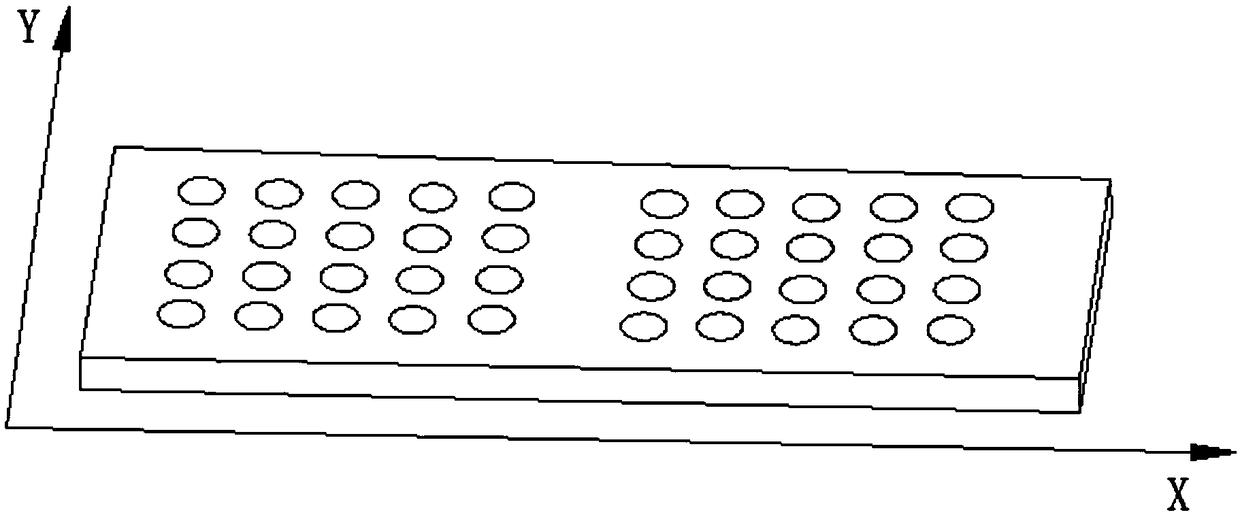

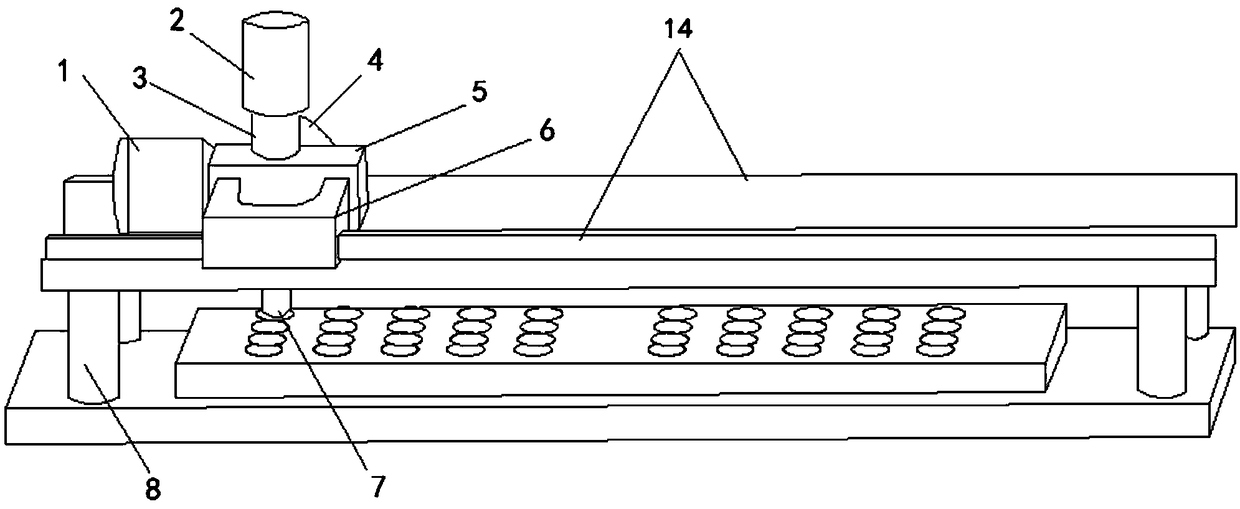

[0040] The present invention will be described in detail below by taking the rapid evaluation and optimization of the wear resistance of Ni60+WC coating as an example to examine the influence of the WC ceramic phase content and size on the wear resistance of the coating. The wear device structure used in the embodiment is as Figure 2-4 shown.

[0041] from figure 2 It can be seen that it includes a support with a sample platform, an X-direction displacement adjustment mechanism, a Y-direction displacement adjustment mechanism, a force measurement and transmission module 3 and a computer control system (not shown in the figure), wherein:

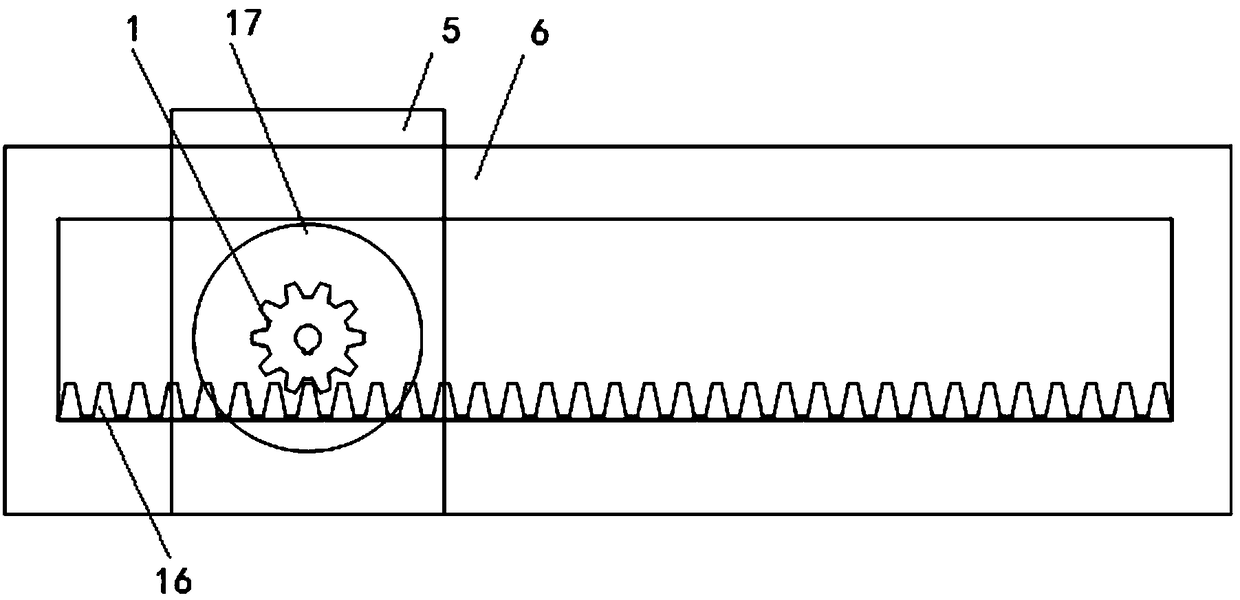

[0042] The X-direction displacement adjustment mechanism and the Y-direction displacement adjustment mechanism are arranged on the top of the bracket 8: the X-direction displacement adjustment mechanism includes the X-direction rail 14, the X-direction displacement slider 6 and the X-direction drive motor 4, and the X-direction drive motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com