Operation method and device for vibratory mixing laboratory test of asphalt mixture

A technology of asphalt mixture, indoor test, applied in the direction of measuring device, material inspection product, analysis material, etc.

Active Publication Date: 2021-06-15

CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] The purpose of the present invention is to provide a vibratory mixing indoor test device for asphalt mixture, which solves the problem of "agglomerates" of fine aggregates and fillers in asphalt mixture, and overcomes the friction and viscous force between the aggregated material particles

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0045] The comparison between conventional non-vibration mixing and vibrating mixing of asphalt mixture indoor test device:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| eccentricity | aaaaa | aaaaa |

Login to View More

Abstract

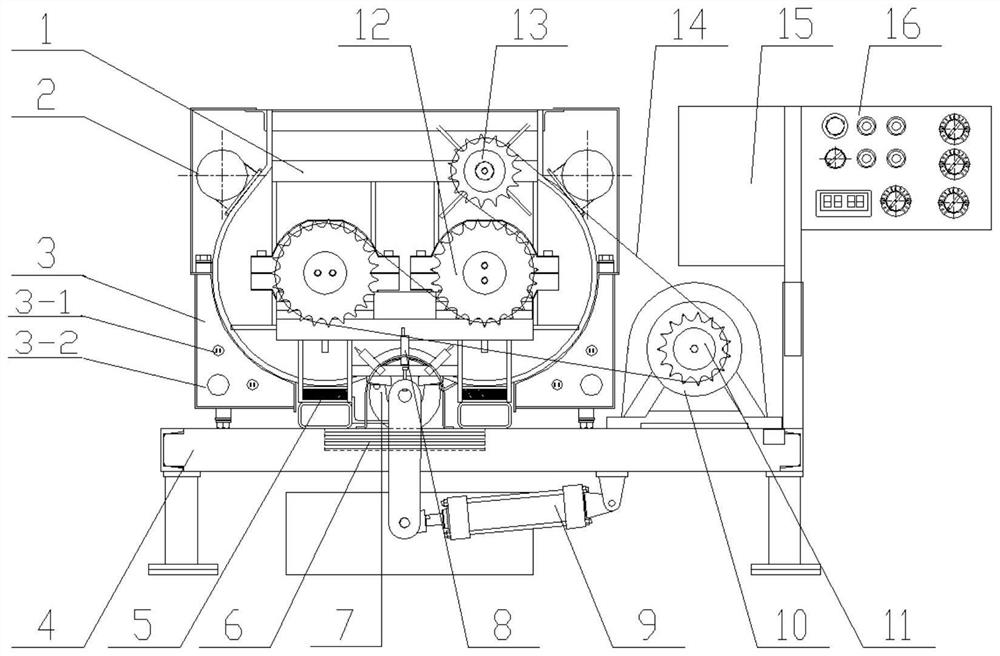

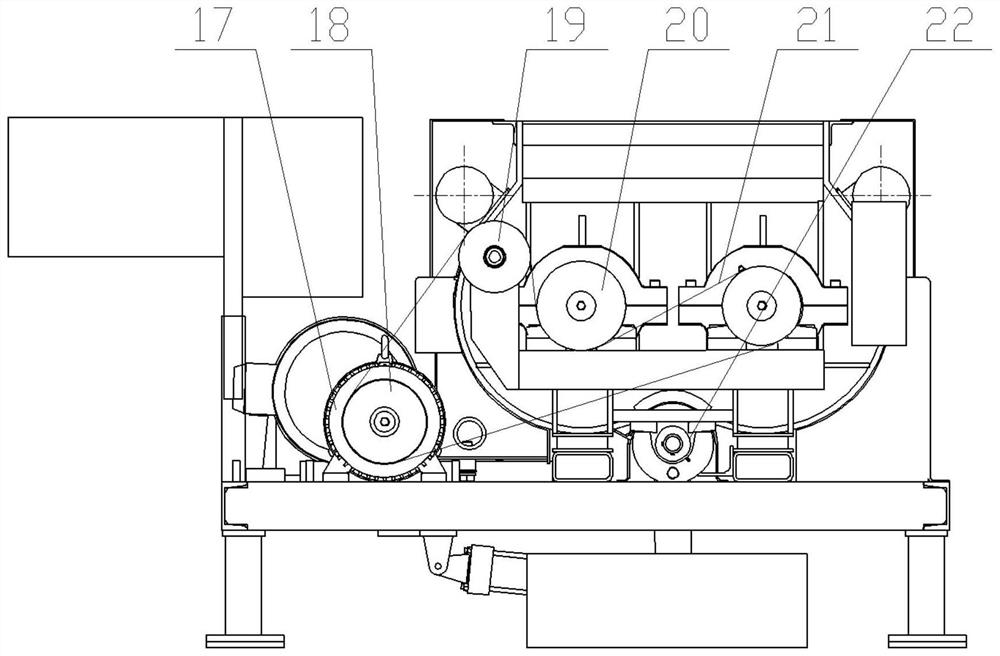

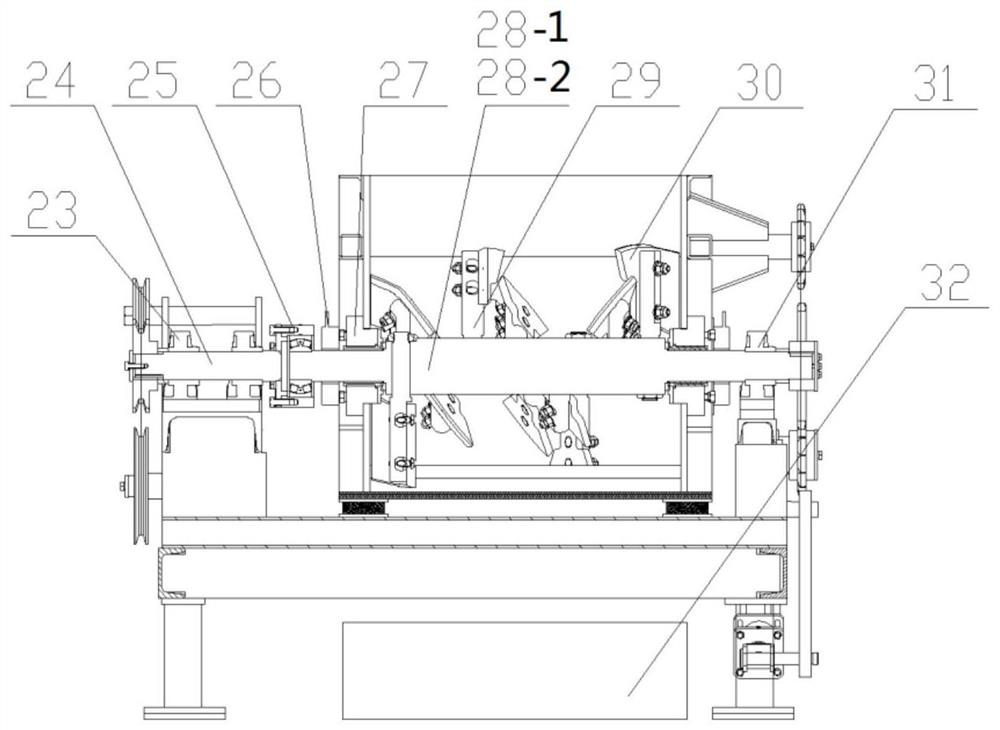

The invention discloses an indoor test operation method and device for asphalt mixture vibration mixing. Asphalt mixture vibratory mixing indoor test device includes mixing tank, rack, mixing tank vibrator, shock absorbing device, stirring motor, stirring shaft, stirring arm, stirring blade, shaft end sealing device, vibration motor, vibrator, material volume It consists of detection device, heating device, heater, electric control system, control panel and discharge door. The operation method of the vibratory mixing indoor test device for asphalt mixture realizes simultaneous heating of the mixing tank and the mixing shaft, controllable vibration frequency of the mixing tank and the shaft, controllable vibration amplitude, and controllable discharge volume. The invention is easy to operate, easy to popularize and apply, each material component is evenly redispersed, the porosity is reduced, and the mixing quality of the mixture is improved; it is of great significance for stimulating the potential of the material, improving the road performance of the asphalt pavement, and prolonging the service life of the asphalt pavement.

Description

technical field [0001] The invention belongs to the technical field of road engineering, and relates to an indoor test operation method and device for asphalt mixture vibration mixing. Background technique [0002] With the development of road construction and research in our country, according to relevant highway statistics and construction experience in various places, the main problem of asphalt pavement is the gradual damage of the road surface caused by local damage, which is often one or two years after the pavement is completed. Early failure in years or years in the form of cracks, water damage, loosening, potholes, and excessive car removal. Early failure of asphalt pavement has always been a major problem in the engineering field. The inhomogeneity of asphalt mixture is the main cause of early failure of asphalt pavement. The degree of uniformity of asphalt mixture is directly related to the mechanical properties and service life of asphalt pavement. [0003] Asph...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N33/42G01N1/44G01N1/38

CPCG01N1/38G01N1/44G01N33/42G01N2001/386

Inventor 郑健龙张良奇张军辉刘韡堃李冠峰黄拓孔鲜宁李鹏

Owner CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com