Method for extracting high-frequency current signals through permanent-magnet motor pulse vibration injection method

A high-frequency current, permanent magnet motor technology, applied in the control of generators, motor control, motor generator control and other directions, can solve problems such as interference with high-frequency current, current distortion, inability to excite, etc., to prevent amplitude attenuation, prevent Phase lag, effect of reducing delay time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

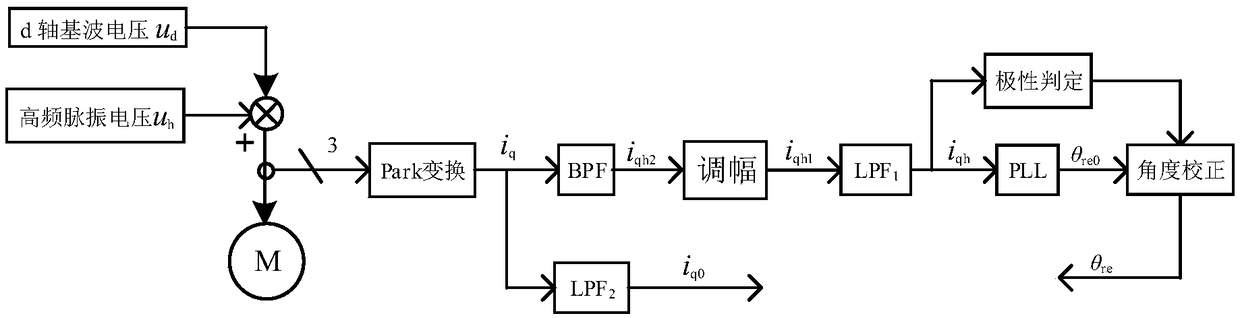

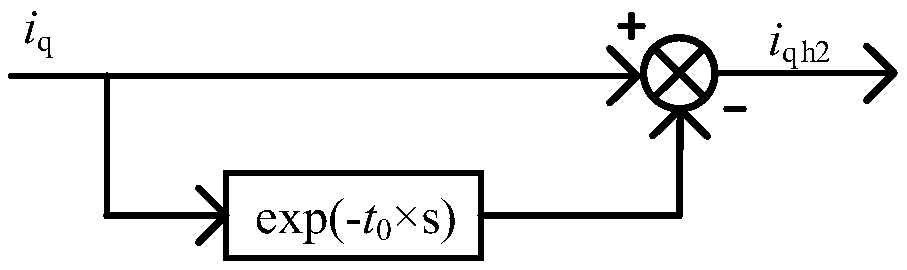

[0045] This embodiment is based on the traditional high-frequency current signal extraction process, and uses a pure delay link instead of a band-pass filter to prevent phase lag and amplitude attenuation of the high-frequency current signal while accurately extracting high-frequency current. Moreover, the DSP program implementation method of the pure delay link is further improved, and the delay time of filtering processing is reduced.

[0046] This embodiment is realized through the following technical solution, a method for extracting high-frequency current signals by the pulse vibration injection method of a permanent magnet motor. The specific implementation process of the current extraction method will be analyzed below in combination with the pulse vibration injection method.

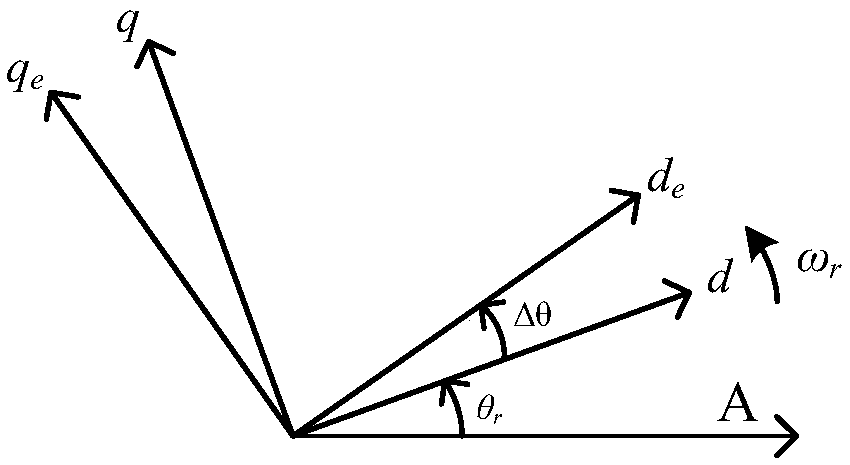

[0047] (1) Sampling the phase current of the motor and performing Pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com