Substep clamping-type valve prosthesis and conveying system thereof

A valve prosthesis and delivery system technology, which is applied in the field of medical devices, can solve the problems of the fatigue resistance of the clamping body, the impact of the clamping capacity of the clamping body, and the unsatisfactory clamping stability. clamping effect, avoid contact, increase the effect of the clamping surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

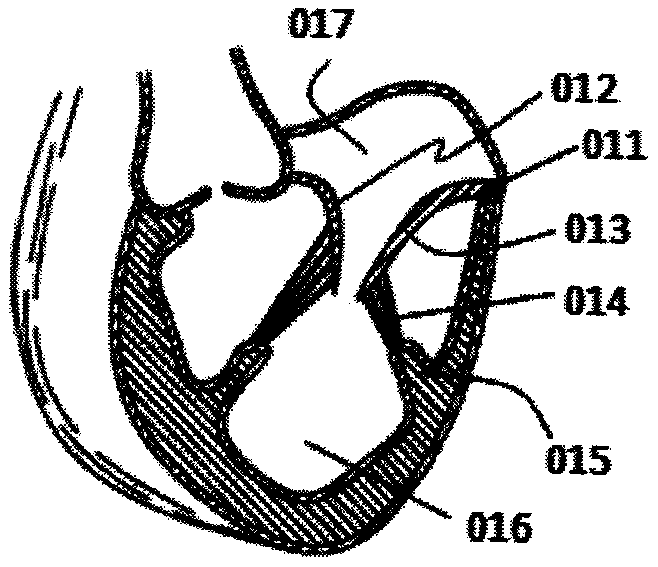

[0054] like Figure 1a as shown, Figure 1a The left atrium 017 and the left ventricle 016 of the left half of the heart are shown, and blood can flow into the left ventricle 016 from the left atrium 017 in one direction. At the junction of the left atrium 017 and the left ventricle 016, it is the mitral valve body of the heart, which includes the mitral valve ring 011, the anterior valve 012, the posterior valve 013, the chordae 014, the papillary muscle 015, the anterior valve 012 and the posterior valve The petals 013 are connected to the corresponding papillary muscles 015 through their respective chordae 014 . In a healthy heart organ, when the papillary muscle 015 contracts, it pulls the chordae 014, and the mitral valve body is in a conduction state; when the papillary muscle 015 relaxes, the chordae 014 is relaxed, and the mitral valve body is in a closed state.

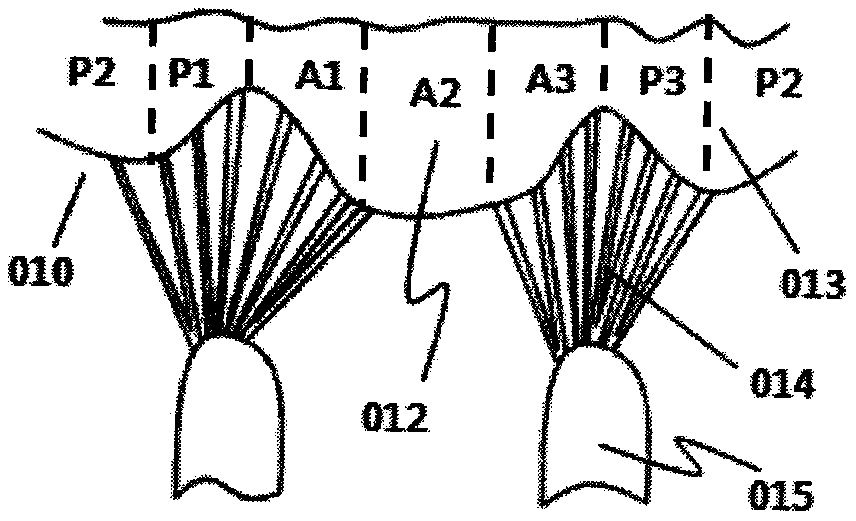

[0055] like Figure 1b As shown, those skilled in the art usually divide the mitral valve into several ...

specific Embodiment 2

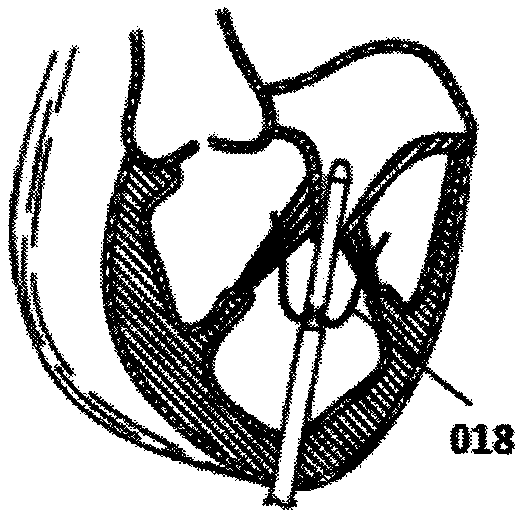

[0078] like Figures 11a-11c As shown, as another embodiment, a step-by-step clamping valve prosthesis 200 includes a stent body 210 and two clamping bodies 220, the stent body 210 has a channel 2101 for blood circulation, and the clip The holding body 220 includes a first holding body 221 and a second holding body 222, one end of the first holding body 221 is connected to the support body 210, and the other end of the first holding body 221 is a free end, The second clamping body 222 is connected to the first clamping body 221, and the clamping body 220 has three forms in sequence from compression to complete release, the first form being the first clamping body 221 and the first clamping body 221. The second clamping body 222 is compressed and limited; the second form is that the second clamping body 222 is limited, and the first clamping body 221 can be connected from the anterior valve, the posterior valve, or the anterior valve and the posterior valve of the mitral valve....

specific Embodiment 3

[0095] like Figures 18a-18d As shown, as another embodiment, a step-by-step clamping valve prosthesis 300 is different from the above-mentioned specific embodiments in that the leaflet body 330 is not pre-fixed on the stent body 310, but is After the stent body 310 is completely released, the leaflet body 330 is released in the stent body 310 again. In order to realize the above-mentioned technical solution, the present invention also provides a delivery system 360 of a step-by-step clamping type valve prosthesis, which includes a step-by-step clamping type valve prosthesis 300, an outer sheath 361, a stent sheath 362, a stent The sheath core 363 and the clamping body sheath 364, the sub-step clamping valve prosthesis 300 includes a stent body 310 and at least one clamping body 320, the stent body 310 has a channel for blood circulation, the clamping The body 320 includes a first clamping body 321 and a second clamping body 322, one end of the first clamping body 321 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com