Preparation method of heat-treated 1500 MPa-grade wheel

A wheel and grade technology, applied in the field of preparation of 1500MPa grade heat-treated wheels, can solve problems such as weak resistance to deformation, and achieve the effects of increased load-bearing capacity, uniform vapor film, and consistent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A preparation method for a 1500MPa level heat-treated wheel, comprising the following steps:

[0033] Step 1) select steel, the chemical composition mass percentage of steel is: C 0.19, Si 0.74, Mn 1.36, P0.01, balance is Fe and unavoidable impurity; The tensile strength of described steel is 670MPa, yield The strength is 450MPa;

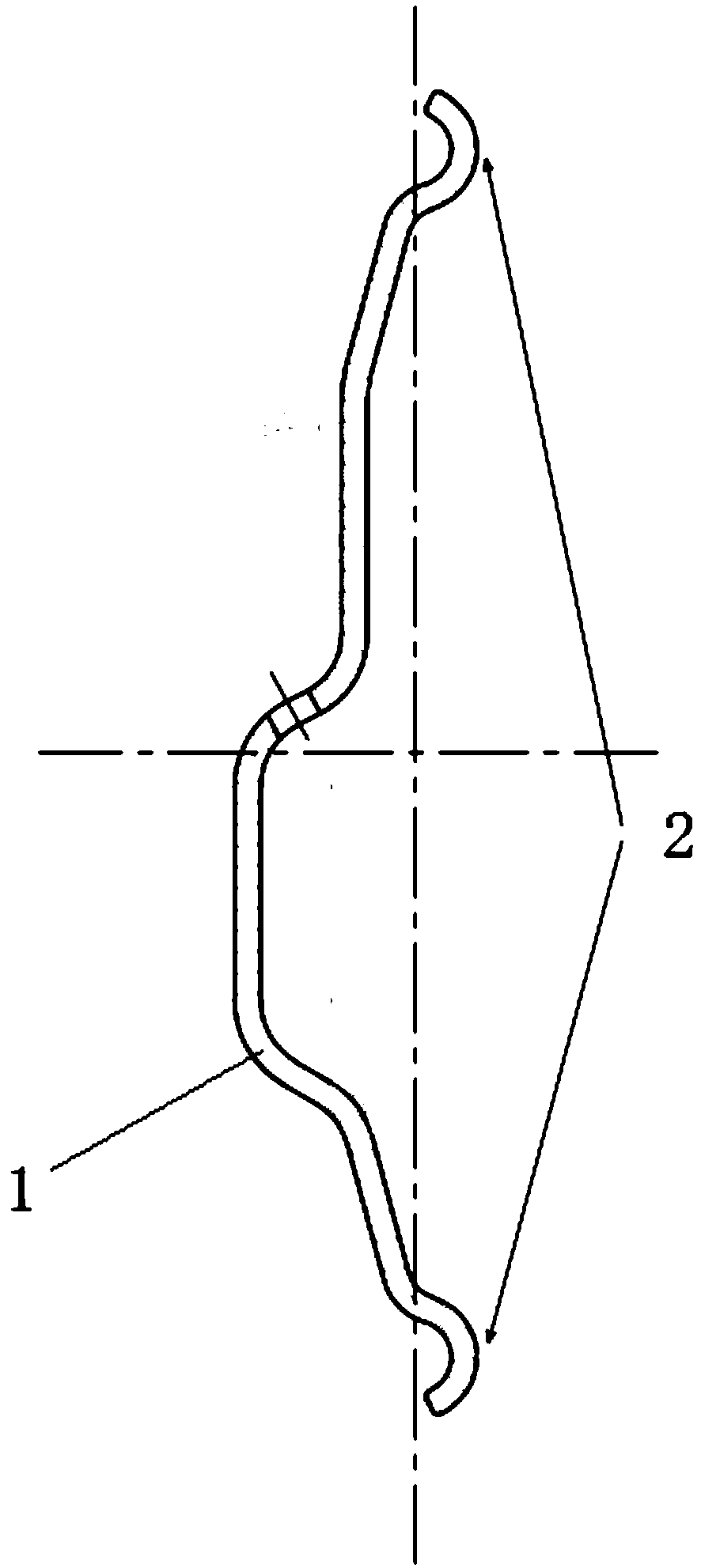

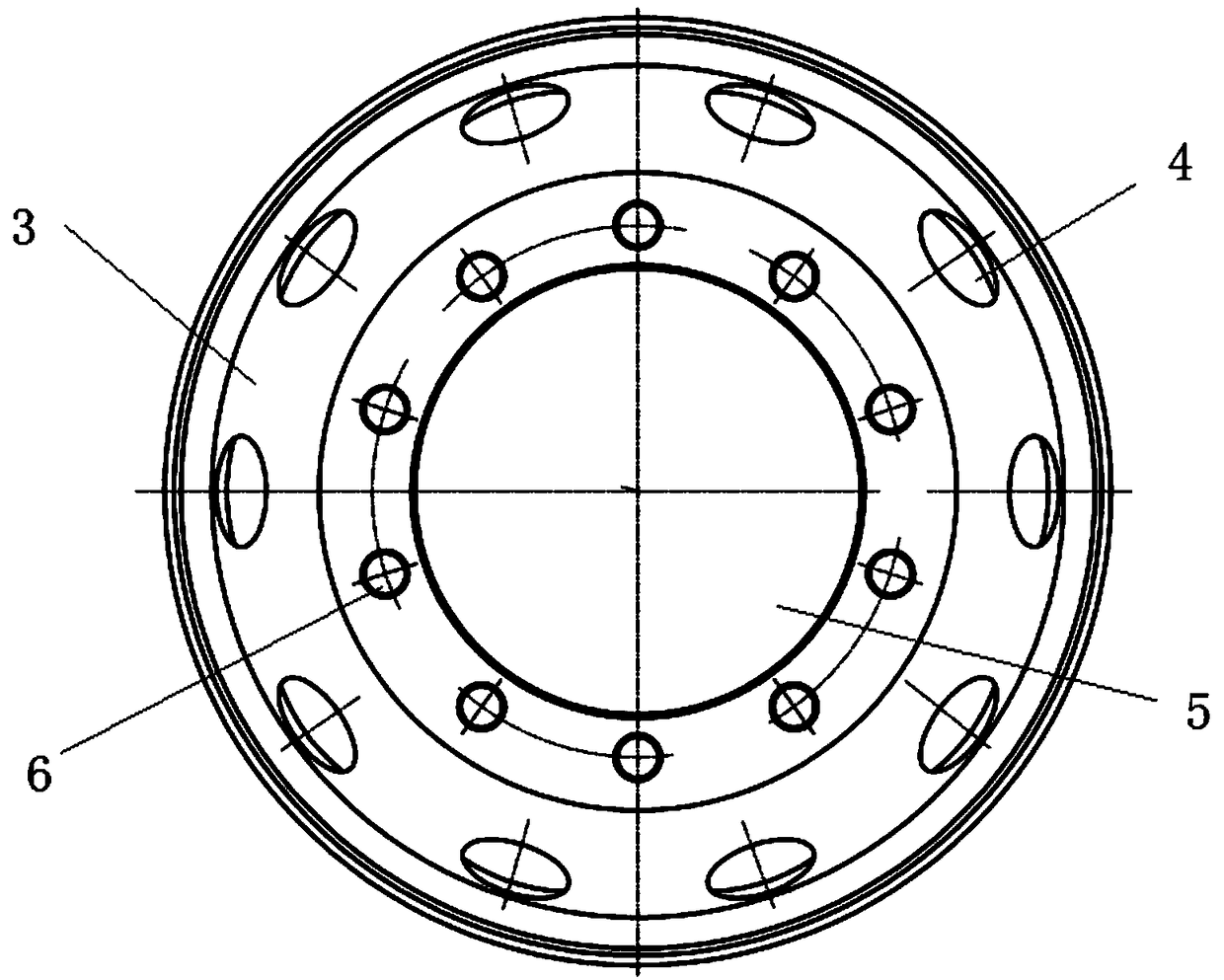

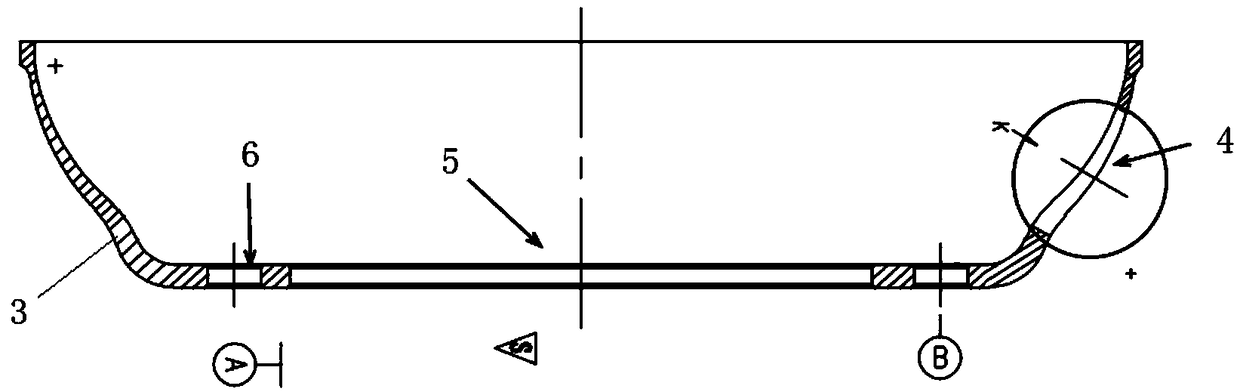

[0034] Step 2) as in Figure 1-4 As shown, the wheel spoke 3 with a qualified size is manufactured by using a conventional production process with steel, the thickness of the spoke sheet is 9 mm, and the thickness of the four air holes after processing is 5.5 mm, and the wheel rim 1 with a qualified size is manufactured with a conventional production process with steel. After the flash butt welding process, the weld seam is annealed, and the expansion amount of the expansion process is 25mm; the wheel spoke 3 and the wheel rim 1 are made of a qualified wheel by synthetic welding process, and the welding wire composition is: C 0.07, Mn 1.4, S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com