A method for testing the packaging effect of soft pack batteries

A soft-pack battery and inspection method technology, which is applied in the direction of measuring devices, using stable tension/pressure to test material strength, material defect testing, etc., can solve the problem of not being able to reflect whether there are pores at the microscopic level, whether the combination is firm, or not being observed , can not be effectively reflected and other problems, to achieve the effect of balanced force, saving time and labor, and high operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) inject 100g of water into the battery intermediate product after primary packaging;

[0037] (2) Carry out secondary encapsulation directly to it;

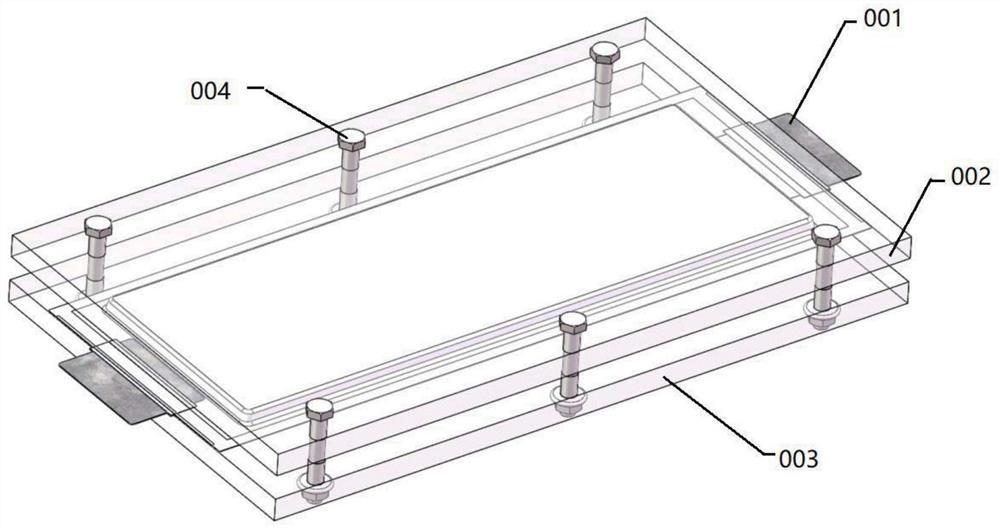

[0038] (3) if figure 1 As shown, two transparent PC boards 002, 003 are used to stick to the top and bottom of the battery under test 001, and the two PC boards 002, 003 are fixed with six pairs of bolts and nuts 004, and the distance between the two boards is 11mm;

[0039] (4) Put the battery clamped by the splint into the oven and start heating from room temperature (25°C) at a heating rate of 5°C / min. After heating to 100°C, it becomes heat preservation, and the temperature in the oven is kept at 100±2°C;

[0040] (5) Record the time from the start of the oven heat preservation to the thermal expansion breach of the battery. If the time is greater than 8 minutes, it is qualified. If it is lower than this value, the packaging is unqualified. Record the position of the breach and give feedback to improve the packagin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com