Battery module

A battery module and battery technology, which is applied to batteries, battery pack components, nickel batteries, etc., can solve the problems that the entire battery module or battery pack cannot be used normally, the replacement of a single battery is inconvenient, and the use cost is high, and it can save money. The effect of production cost, simple structure and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

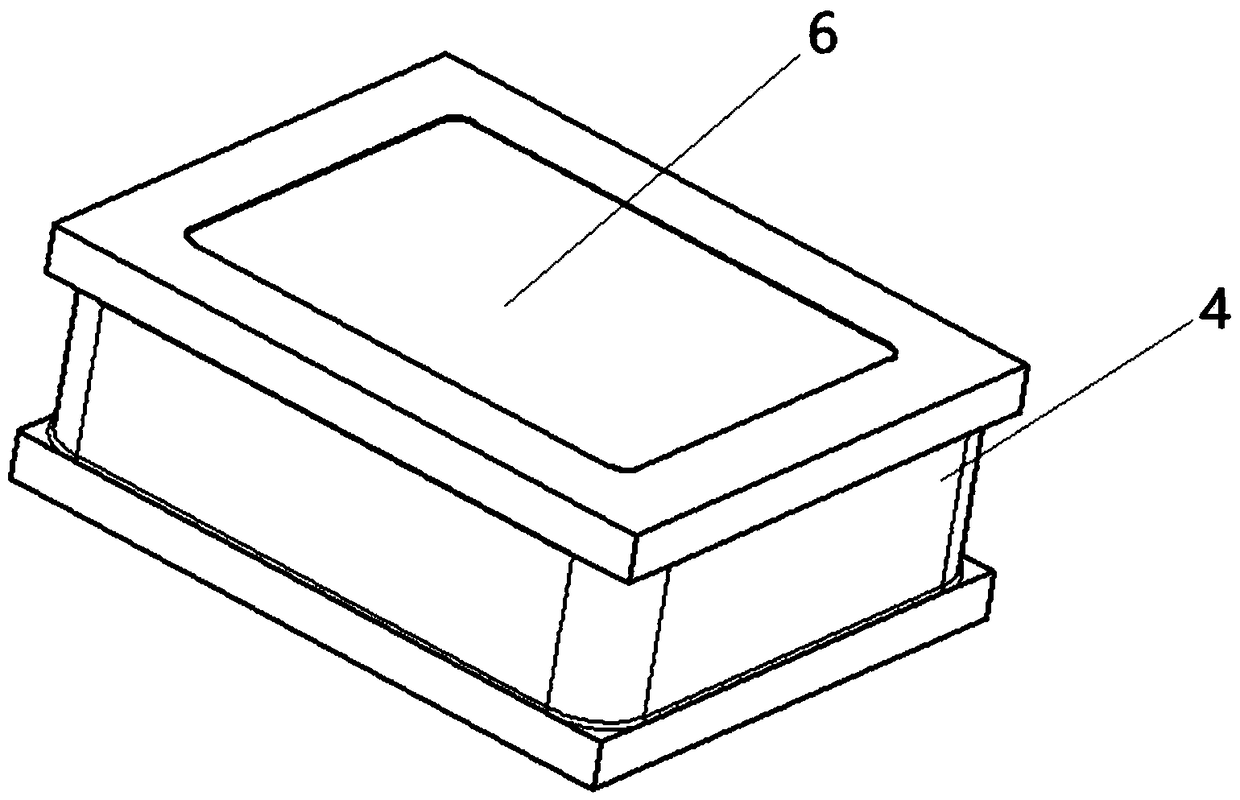

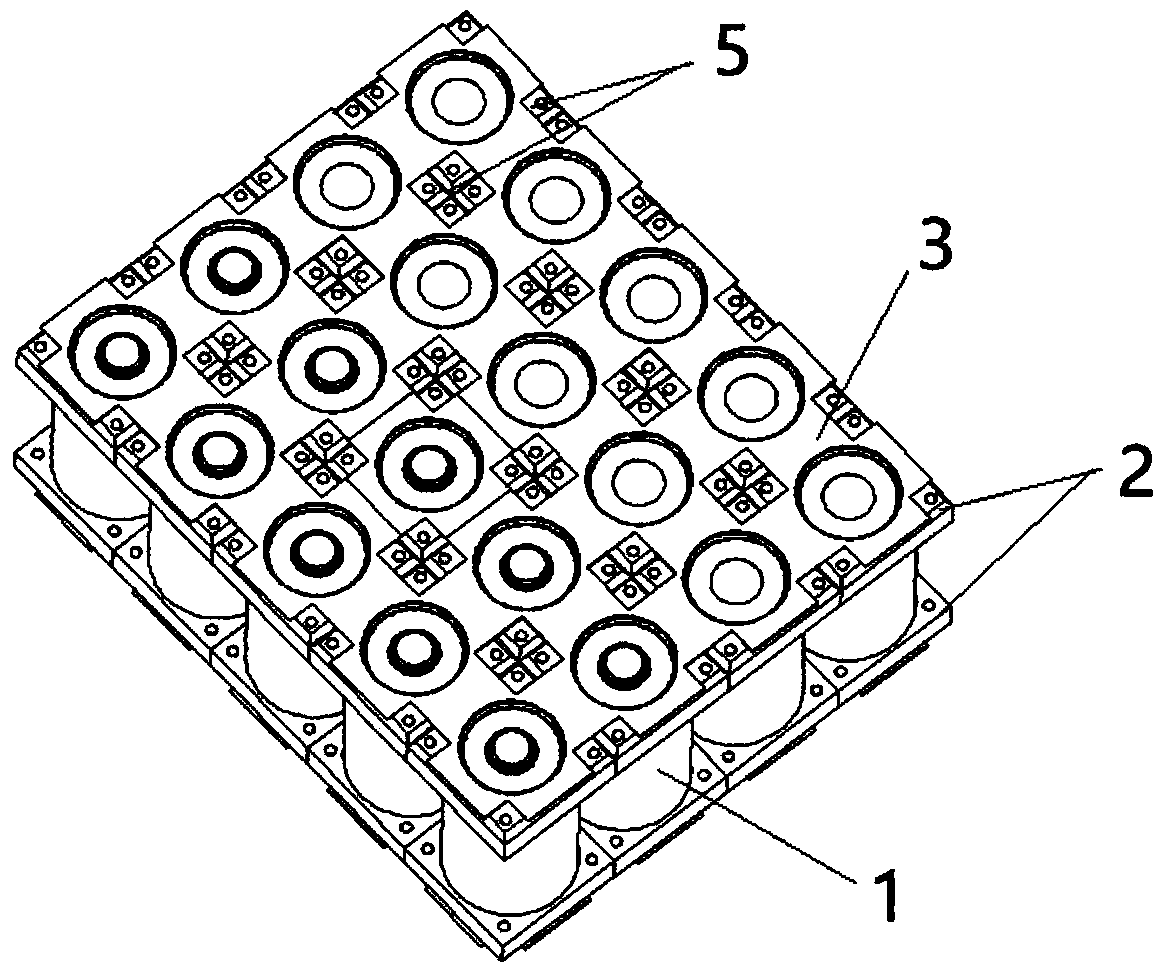

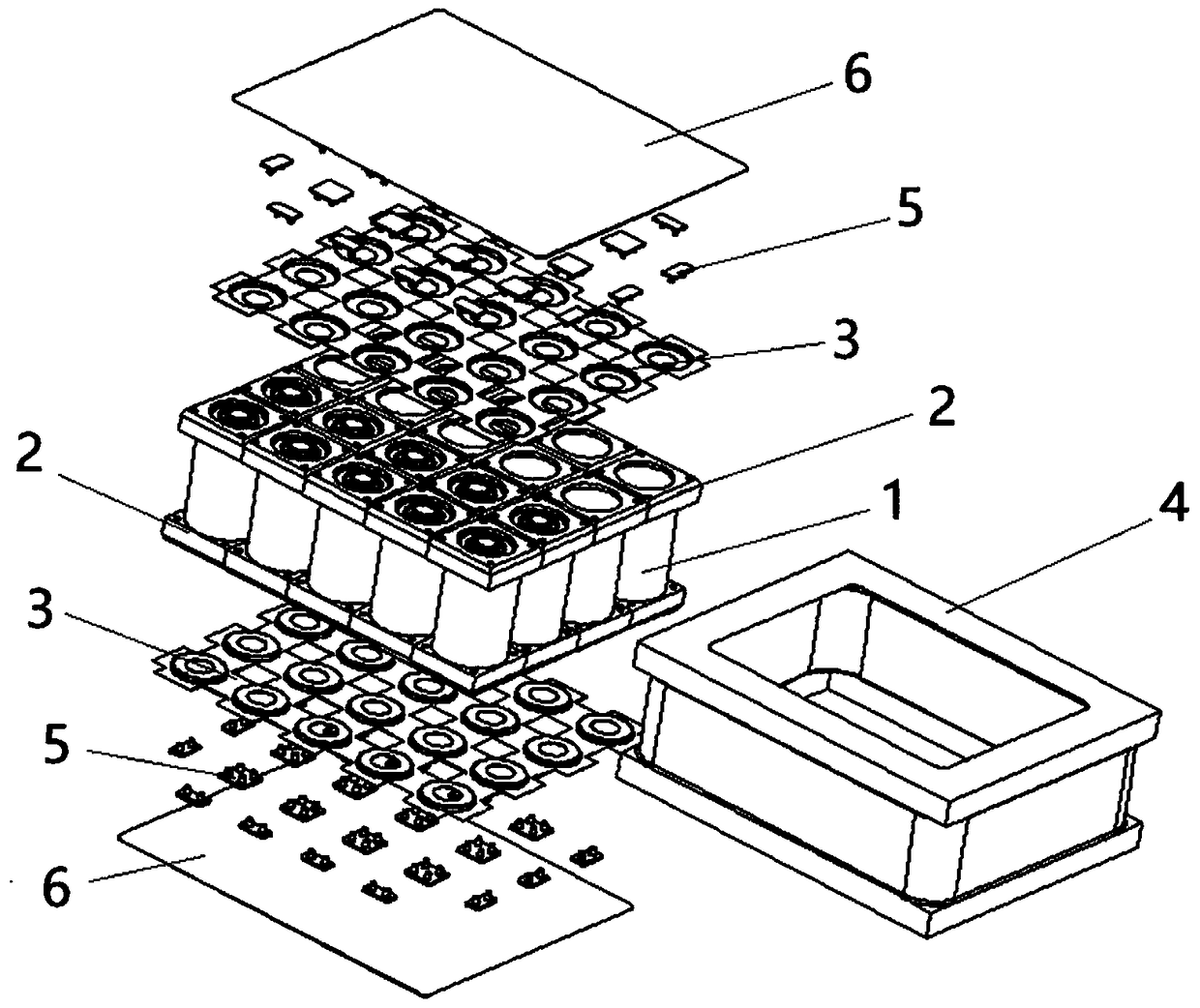

[0020] A battery module, as shown in Figure 1(a), Figure 1(b), and Figure 1(c), includes twenty circular single cells 1, forty end snap rings 2, two connecting Component 3 and heat-shrinkable film 4; as shown in Figure 2 (a) and Figure 2 (b), the end snap ring 2 is a square structure as a whole, and one end surface of the end snap ring 2 is provided with a battery installation groove 21, and the battery The bottom of the mounting groove 21 is provided with a first through hole 22, the diameter of the first through hole 22 is larger than the diameter of the positive cap of the single battery 1 and smaller than the maximum diameter of the uncoated part of the positive cap of the single battery 1, and the end is clamped. The bottom of the battery mounting groove 21 of the ring 2 is located at the peripheral position of the first through hole 22, and a ring of raised parts 23 is vertically provided. steel shell, and is used to limit the negative terminal of the single battery 1, a...

Embodiment 2

[0024]A battery module, the structure of which is similar to that of the battery module in Embodiment 1, the difference is that the number of single cells is sixteen, and the sixteen cells are arranged in two rows, Sixteen single cells are connected in series with each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com