Preparation of polyacrylamide-coated composite silica gel and application of composite silica gel as chromatographic filler

The technology of polyacrylamide and silica gel is applied in the field of high-performance liquid chromatography separation and analysis, which can solve the problems of complicated preparation process and expensive chromatographic column, and achieve the effects of reducing laboratory cost, excellent separation effect and low preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

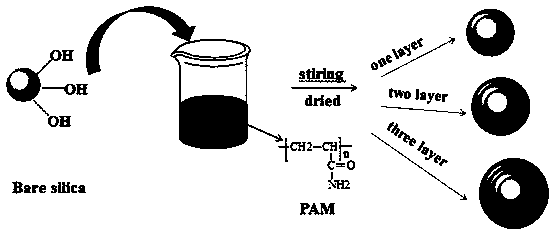

[0023] PAM@SiO 2 The preparation of packing comprises the following steps:

[0024] (1) Silica gel activation: take 8 g of silica gel, heat and reflux with 6 mol / L hydrochloric acid for 4 h, wash with water until neutral, and vacuum dry at 70 °C for 6 h for later use;

[0025] (2) Preparation of polyacrylamide solution: Take 0.2 g of polyacrylamide solid particles with a molecular weight of 10 million, add them to 1000 mL of distilled water, and stir magnetically for 24 h to dissolve them evenly;

[0026] (3) Surface modification and curing of silica gel: Take 5 g of activated silica gel, add it to 150 mL polyacrylamide solution, treat it ultrasonically for 10 min, and then stir it magnetically at 70 °C until the solution evaporates to dryness. Wash once with aqueous solution. The composite microspheres prepared above were dried under vacuum at 70°C for 8 h to cure the polyacrylamide molecules coated on the silica gel surface;

[0027] (5) Polyacrylamide-wrapped composite s...

Embodiment 2

[0028] Embodiment 2, the chromatographic separation of ribose

[0029] PAM@SiO 2 Preparation of chromatographic column: PAM@SiO prepared in Example 1 was prepared by high-pressure homogenization 2 The chromatographic filler is packed into a 150×4.6mm stainless steel liquid chromatographic column for the separation and analysis of sugar compounds. During the filling process, the dispersion liquid is carbon tetrachloride, the displacement liquid is n-hexane, and the pressure is 40 MPa.

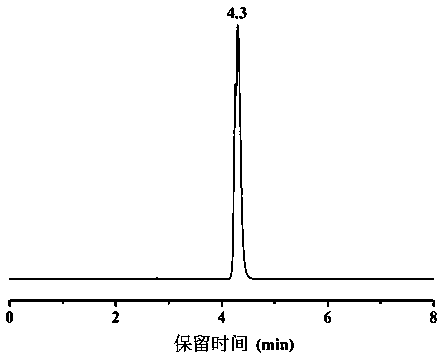

[0030] Chromatographic separation of ribose: chromatographic analysis conditions are as follows: mobile phase is 90% acetonitrile aqueous solution; flow rate is 1.0 mL / min; evaporative light scattering detector, gas flow rate is 4 L / min, temperature is 115°C; injection volume is 20 µL .

[0031] The liquid chromatogram of ribose is shown in figure 2 . Under the above chromatographic analysis conditions, the retention time of ribose is 4.3 min, and the column efficiency is about 50000 / m.

Embodiment 3

[0032] Embodiment 3, the chromatographic separation of arabinose

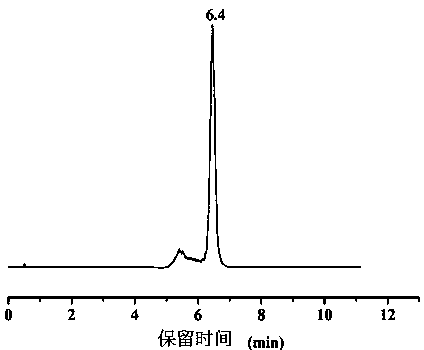

[0033] PAM@SiO 2 Preparation of chromatographic column: PAM@SiO prepared in Example 1 was prepared by high-pressure homogenization 2 The chromatographic filler is packed into a 150×4.6mm stainless steel liquid chromatographic column for the separation and analysis of sugar compounds. During the filling process, the dispersion liquid is carbon tetrachloride, the displacement liquid is n-hexane, and the pressure is 40 MPa.

[0034] Chromatographic separation of arabinose: chromatographic analysis conditions are as follows: mobile phase is 90% acetonitrile aqueous solution; flow rate is 1.0 mL / min; evaporative light scattering detector, gas flow rate is 4 L / min, temperature is 115 °C; 20 µL.

[0035] The liquid chromatogram of arabinose is shown in image 3 . The retention time of arabinose is 6.4 min, and the column efficiency is about 60000 / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com