Mono-disperse noble metal-loaded single-layer hydrotalcite material as well as preparation method and application thereof

A noble metal, monodisperse technology, applied in chemical instruments and methods, preparation of imino compounds, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of expensive noble metals, difficult recycling, and limited noble metal homogeneous catalysts Application and other issues, to achieve the effect of simple preparation method, improved accessibility, improved conversion rate and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Take 6mmol Ni(NO 3 ) 2 ·6H 2 O, 2mmol Fe(NO 3 ) 3 ·9H 2 O and 180μmol RuCl 3 ·3H 2 O, make solution A in 200ml deionized water.

[0026] 2. Take 20ml formamide and add 180ml water to make solution C.

[0027] 3. Take 1g of NaOH and dissolve it in 100ml of water to prepare solution B.

[0028] 4. Drop solution A and solution B into solution C within 30 minutes, and control the pH at about 10.

[0029] 5. The reaction solution obtained in step 4 is filtered, and fully washed with deionized water until the pH value of the supernatant is less than 8, to obtain a monodisperse precious metal-supported monolayer hydrotalcite catalyst material.

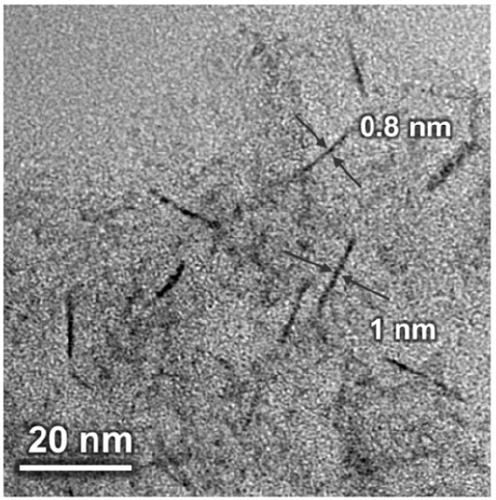

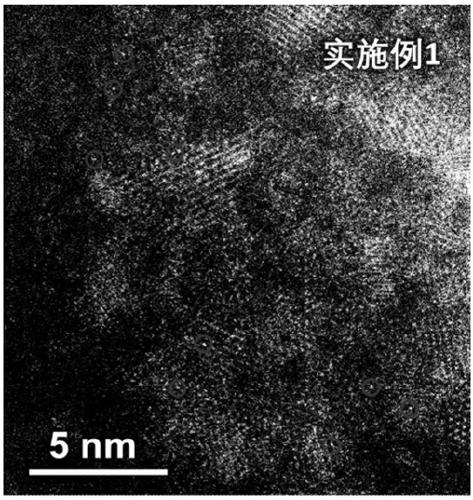

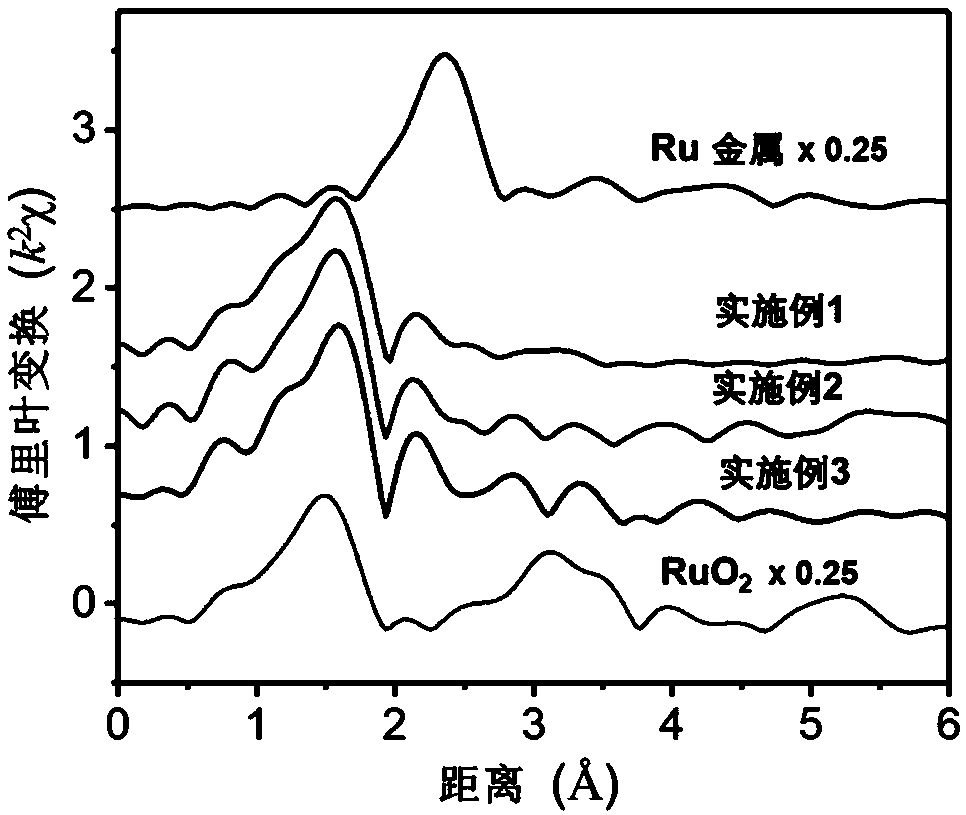

[0030] Characterize the catalyst: by figure 1 It can be seen that the single-layer monodisperse precious metal hydrotalcite catalyst synthesized by this method has a particle size of about 20-30 nm and a thickness of about 1 nm, and the synthesized catalyst is a single layer. by figure 2 It can be seen that only the Ru-O coordination peak ...

Embodiment 2

[0033] 1. Take 10mmol Ni(NO 3 ) 2 ·6H 2 O, 5mmol Al(NO 3 ) 3 ·9H 2 O and 0.075mmol RuCl 3 ·3H 2 O, prepared solution A in 40ml deionized water.

[0034] 2. Take 10ml formamide and add 40ml water to make solution C.

[0035] 3. Take 1g of NaOH and dissolve it in 20ml of water to prepare solution B.

[0036] 4. Drop solution A and solution B into solution C within 20 minutes, and control the pH to around 9.

[0037] 5. The reaction solution obtained in step 4 is filtered, and fully washed with deionized water until the pH value of the supernatant is less than 8, to obtain a monodisperse precious metal-supported monolayer hydrotalcite catalyst material.

[0038] by figure 2 It can be seen that only the Ru-O coordination peak around 1.5 can be seen, but the Ru-Ru coordination peak around 2.7 is not seen, which confirms the monodisperse characteristics of Ru.

[0039] 150mg of the monodisperse noble metal-supported monolayer hydrotalcite material prepared above was used as a catalyst. It was...

Embodiment 3

[0041] 1.7.5mmol Mg(NO 3 ) 2 ·6H 2 O, 2.5mmol Al(NO 3 ) 3 ·9H 2 O and 0.3mmol RuCl 3 ·3H 2 O, make solution A in 200ml deionized water.

[0042] 2. Take 20ml formamide and add 180ml water to make solution C.

[0043] 3. Take 2g of NaOH and dissolve it in 100ml of water to prepare solution B.

[0044] 4. Drop solution A and solution B into solution C within ten minutes, and control the pH at about 10.

[0045] 5. The reaction solution obtained in step 4 is filtered, and fully washed with deionized water until the pH value of the supernatant is less than 8, to obtain a monodisperse precious metal-supported monolayer hydrotalcite catalyst material.

[0046] Characterize the catalyst: by figure 1 It can be seen that the single-layer monodisperse precious metal hydrotalcite catalyst synthesized by this method has a particle size of about 20-30 nm and a thickness of about 1 nm, and the synthesized catalyst is a single layer.

[0047] The invention adopts a one-step co-precipitation method to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com