A kind of nitrogen-doped graphene/nano titanium dioxide photocatalyst and its preparation method and application

A technology of nitrogen-doped graphene and nano-titanium dioxide, which is applied in the direction of physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, chemical instruments and methods, etc., which can solve unfavorable mass production and high production costs , complex steps and other issues, to achieve the effect of improving photocatalytic activity, improving affinity, and improving adsorption and degradation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

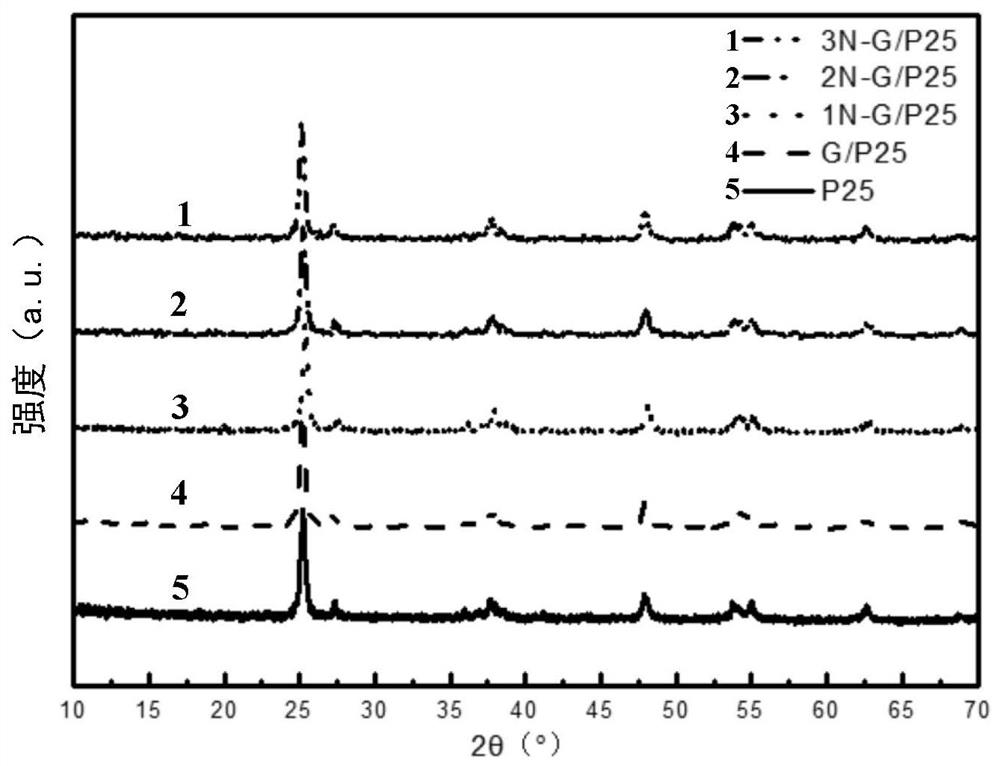

Embodiment 1

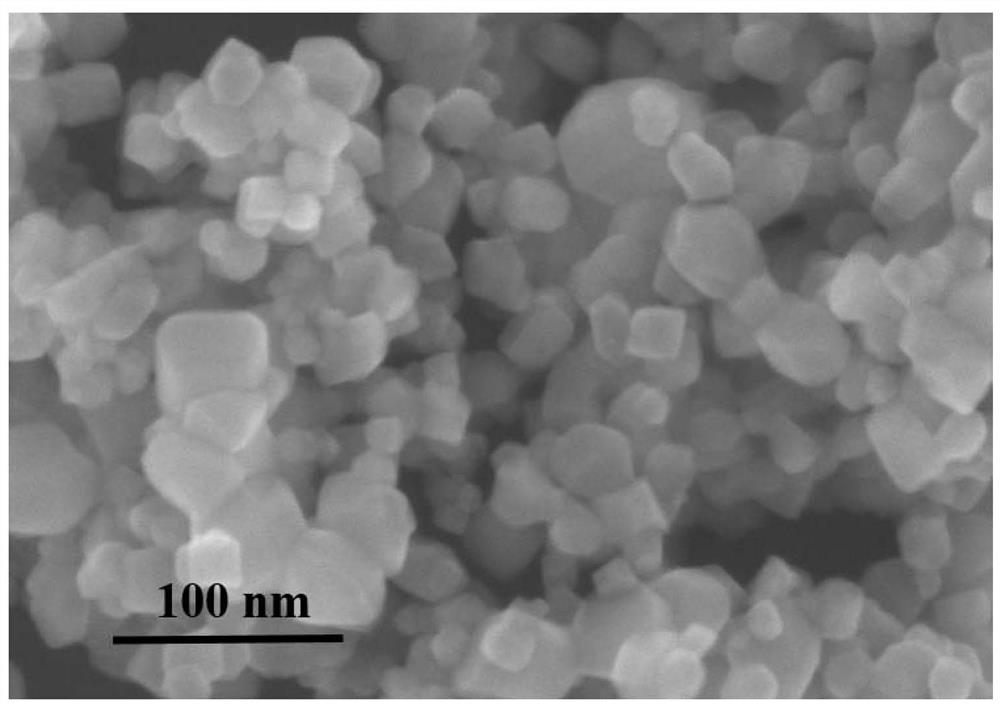

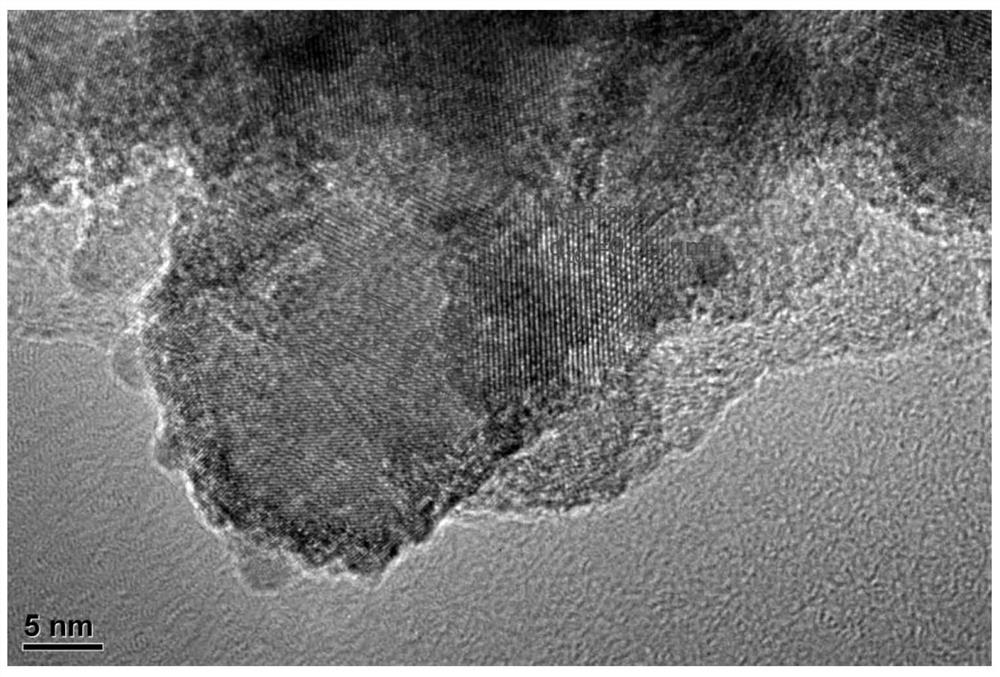

[0070] First, disperse 1g of titanium dioxide in 40ml of deionized water, stir thoroughly to obtain a suspension of titanium dioxide, then place the suspension on a stirring table, add 500 μl of hydrochloric acid solution with a concentration of 37% dropwise while stirring, adjust the pH to 2, and then add 10ml Graphene oxide aqueous solution with a mass fraction of 1 mg / ml. Adjust the temperature of the stirring table to 100°C, and stir while heating until the water is completely volatilized to obtain a graphene oxide / titanium dioxide composite;

[0071] Dissolve 10mg of dicyandiamide in 20ml of absolute ethanol, and ultrasonically dissolve all of the dicyandiamide; disperse the above 1g of graphene oxide / titanium dioxide composite in absolute ethanol with dicyandiamide, and stir thoroughly for 3 hours to obtain Mix a homogeneous suspension. The suspension was placed in an oven and dried at 80°C to obtain a mixed powder. Put the powder in a suction filtration device, add de...

Embodiment 2

[0076] First, disperse 1g of titanium dioxide in 40ml of deionized water, stir thoroughly to obtain a suspension of titanium dioxide, then place the suspension on a stirring table, add 500 μl of hydrochloric acid solution with a concentration of 37% dropwise while stirring, adjust the pH to 2, and then add 10ml Graphene oxide aqueous solution with a mass fraction of 1 mg / ml. Adjust the temperature of the stirring table to 100°C, and stir while heating until the water is completely volatilized to obtain a graphene oxide / titanium dioxide composite;

[0077] Dissolve 20mg of dicyandiamide in 20ml of absolute ethanol, and ultrasonically dissolve all the dicyandiamide; disperse the above 1g of graphene oxide / titanium dioxide composite in absolute ethanol with dicyandiamide, and fully stir for 3 hours to obtain Mix a homogeneous suspension. The suspension was placed in an oven and dried at 80°C to obtain a mixed powder. Put the powder in a suction filtration device, add deionized ...

Embodiment 3

[0082] First, disperse 1g of titanium dioxide in 40ml of deionized water, stir thoroughly to obtain a suspension of titanium dioxide, then place the suspension on a stirring table, add 500 μl of hydrochloric acid solution with a concentration of 37% dropwise while stirring, adjust the pH to 2, and then add 10ml Graphene oxide aqueous solution with a mass fraction of 1 mg / ml. Adjust the temperature of the stirring table to 100°C, and stir while heating until the water is completely volatilized to obtain a graphene oxide / titanium dioxide composite;

[0083] Dissolve 30mg of dicyandiamide in 20ml of absolute ethanol, and ultrasonically dissolve all the dicyandiamide; disperse the above 1g of graphene oxide / titanium dioxide composite in absolute ethanol dissolved in dicyandiamide, and fully stir for 3 hours to obtain Mix a homogeneous suspension. The suspension was placed in an oven and dried at 80°C to obtain a mixed powder. Put the powder in a suction filtration device, add de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com