Low-rank coal maceral enrichment technology

A technology of micro-component, low-rank coal, applied in solid separation, wet separation, chemical instruments and methods, etc., to enrich the connotation, enhance the value of coal products, and enrich the product structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical method of the present invention easy to understand, the technical solution of the present invention is described by using specific examples in conjunction with the accompanying drawings. It should be pointed out that the embodiments described here are only some of the embodiments of the present invention, rather than the entire implementation of the present invention, and their function is only to provide examiners and the public with a more intuitive and clear way to understand the content of the present invention. Rather than limiting the technical solution of the present invention. On the premise of not departing from the concept of the present invention, all other implementations that can be thought of by those skilled in the art without creative work, and other simple replacements and various changes to the technical solutions of the present invention, all belong to the protection scope of the present invention .

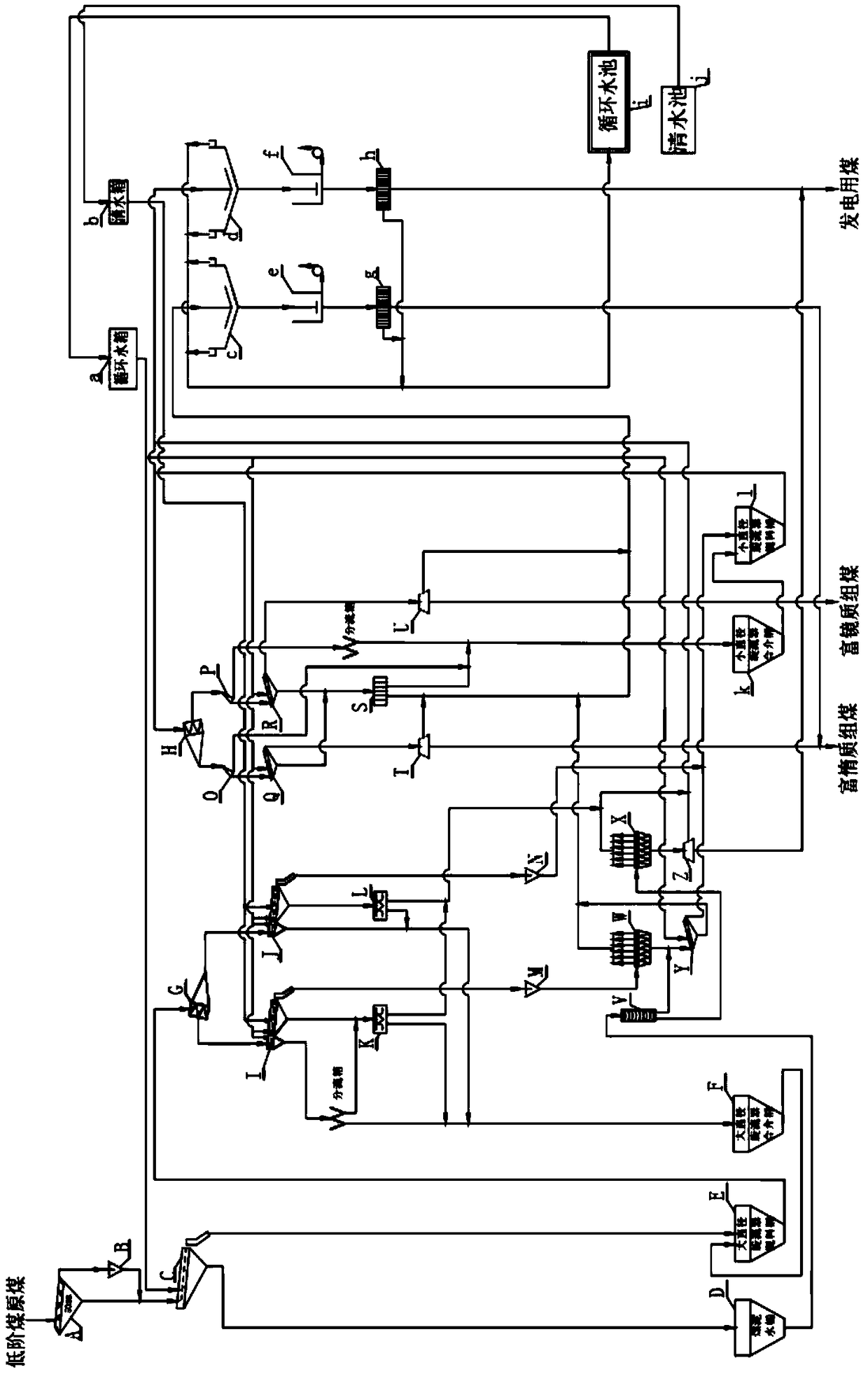

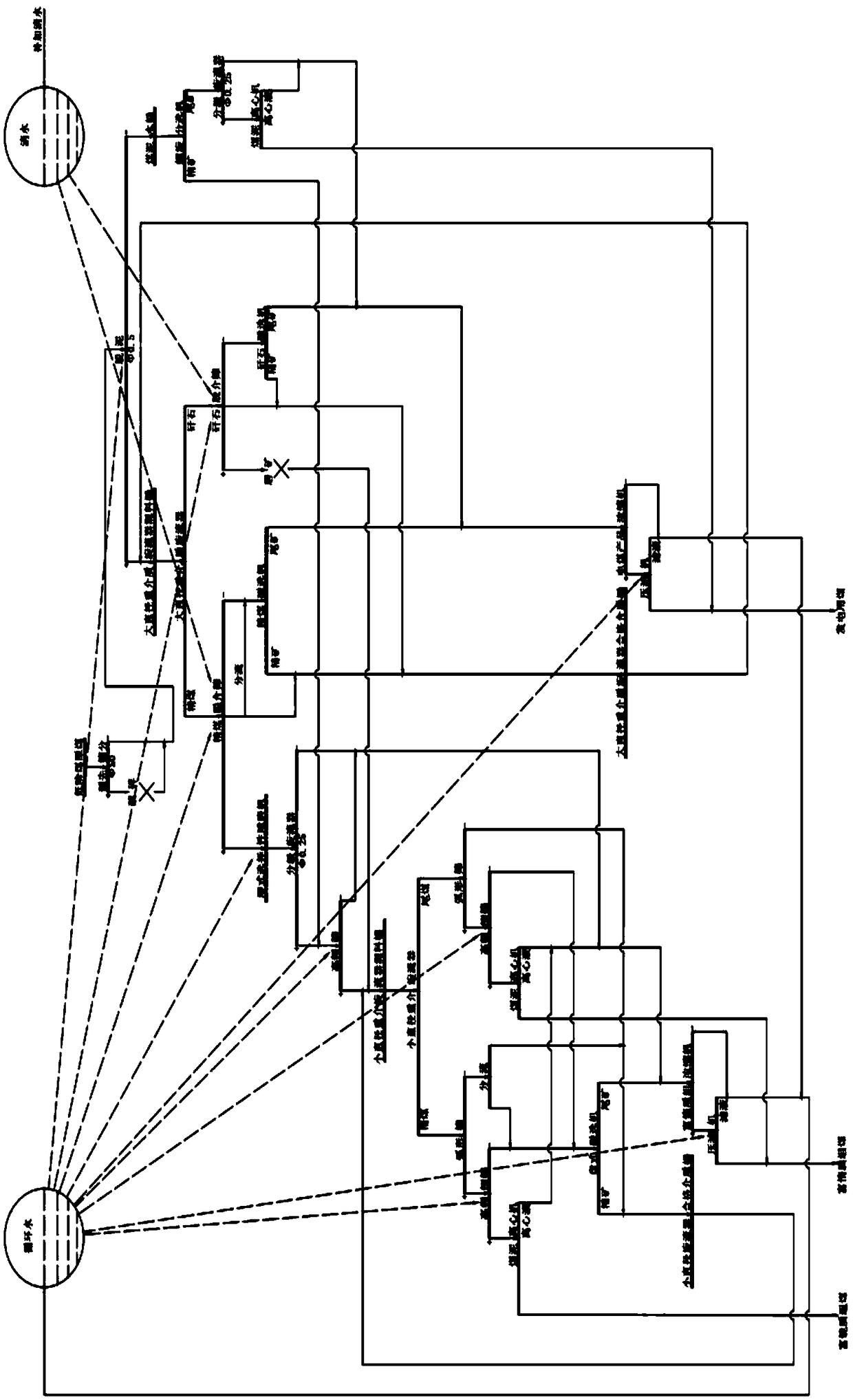

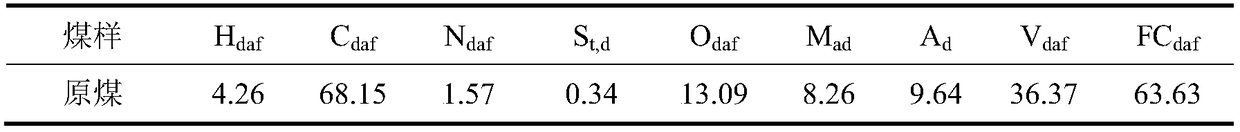

[0030] Such as fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com