Finger tip tight sealing sheet picosecond ultra-fast laser cutting quality control method

A quality control method, ultra-fast laser technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve problems such as deformation, achieve broad application prospects, reduce unevenness of parts, and improve cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A quality control method for picosecond ultrafast laser cutting of fingertip sealant sheet of the present invention comprises the following steps:

[0030] Step 1: Clamp the plate on the fixture of the picosecond ultrashort pulse laser machine tool, the flatness of the clamping surface is less than 0.06mm; the laser output wavelength of the picosecond ultrashort pulse laser machine tool is 532nm, the repetition frequency is 200KHz, and the output average power for 20W.

[0031] Step 2: Use picosecond ultrashort pulse laser machine cutting to form fingertip seams and positioning holes. When cutting, cut in layers according to the thickness of the plate, and use different cutting speeds for each layer;

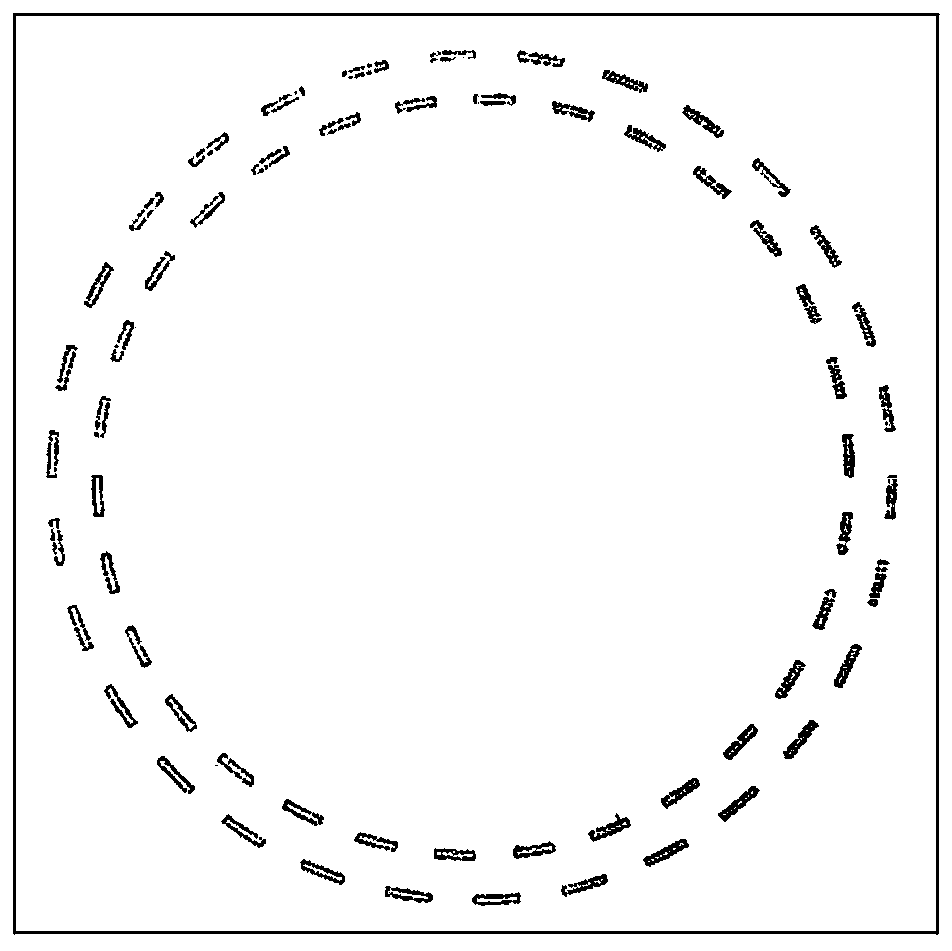

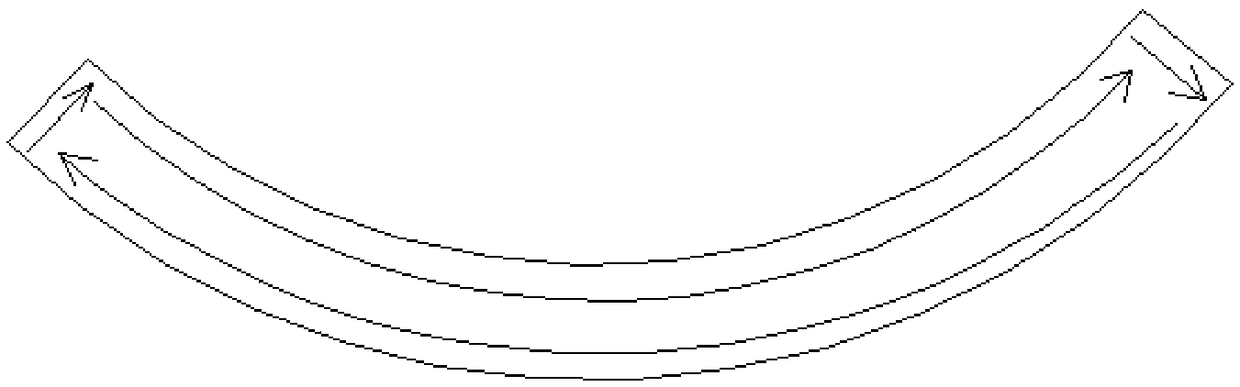

[0032] Step 3: Cut the outer circle and the inner circle by means of arc segment cutting, the cutting sequence is: outer circle, inner circle, inner circle, outer circle, that is, the outer circle is cut with a symmetrical staggered cutting method to form multiple interva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com