Tilting mechanism with control surface

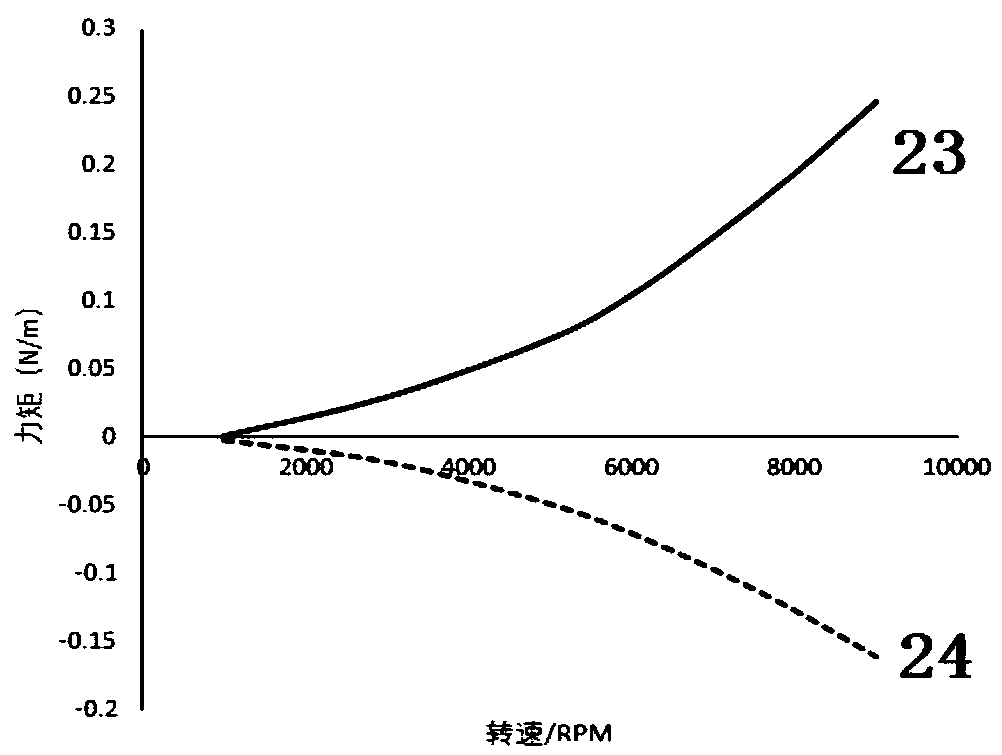

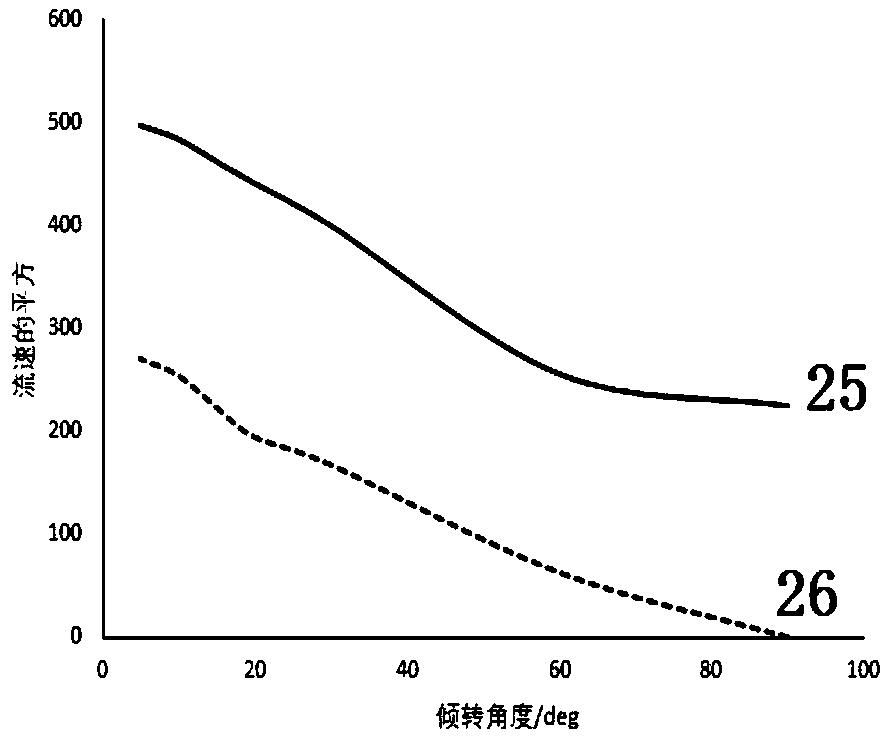

A technology of a tilting mechanism and a rudder surface, applied in the field of aircraft, can solve the problems of the backward tilting rotor affecting aerodynamic performance, poor chain transmission stability, etc., and achieve the effects of low installation accuracy, increased aerodynamic efficiency, and strong resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

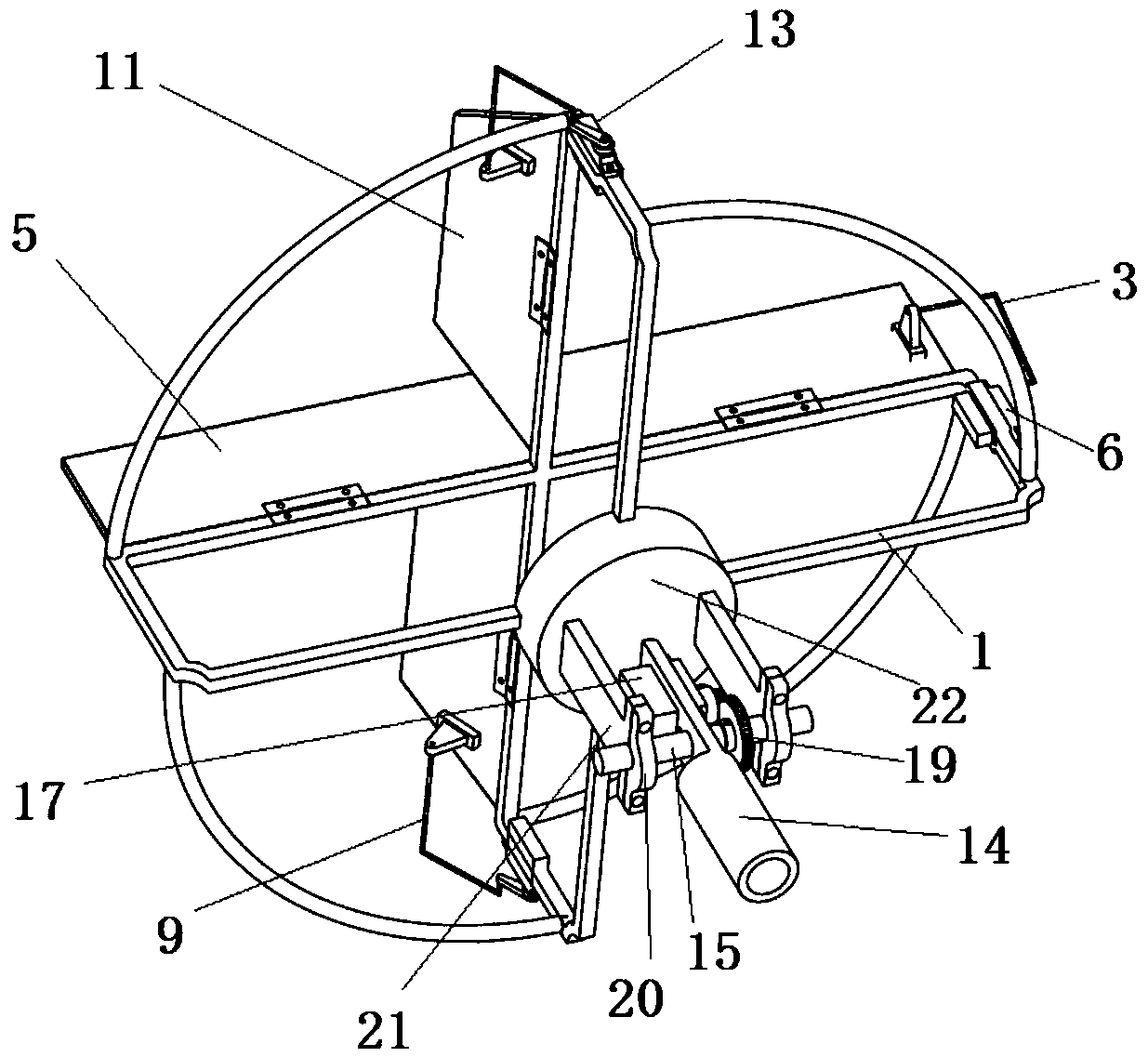

[0035]This embodiment is a tilting mechanism with a rudder surface, including a rudder surface mounting frame 1, a motor base 22, a horizontal rudder surface 5, two vertical rudder surfaces 11, a motor base 22, a tilting shaft 15, a connector and a Connect the mounting frame 14 of the fuselage. Wherein: the horizontal rudder surface 5 is installed on a long side of the horizontal rudder surface frame of the rudder surface installation frame 1 through a hinge, and the two vertical rudder surfaces 11 are respectively installed on the rudder surface installation through a hinge. One long side of the vertical rudder surface frame of the frame, and respectively located on the upper surface side and the lower surface side of the horizontal rudder surface. Both the horizontal rudder surface and the vertical rudder surface are on the same side of the rudder surface installation frame. The motor base 22 is located on the other side of the control surface mounting frame, and is fixed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com