Remote control operation system for rubber-type container gantry crane loading and unloading operation

A remote control and operating system technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of remote operation control difficulty and complexity, different control ranges, and different control methods, so as to improve the efficiency of loading and unloading operations and Production safety, conducive to accurate control, and the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

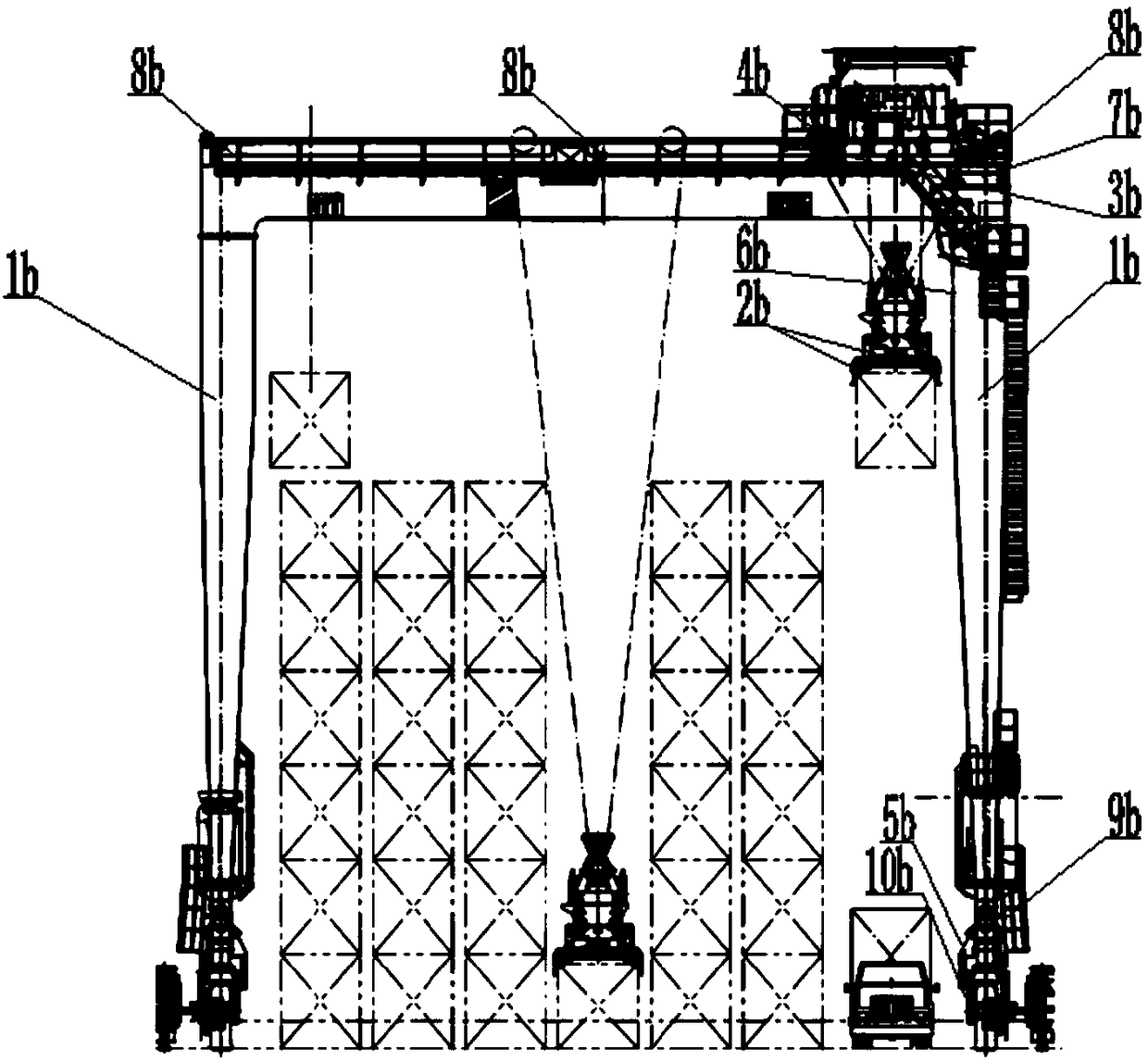

[0030] The specific implementation of the present invention will be described in detail below in conjunction with preferred embodiments.

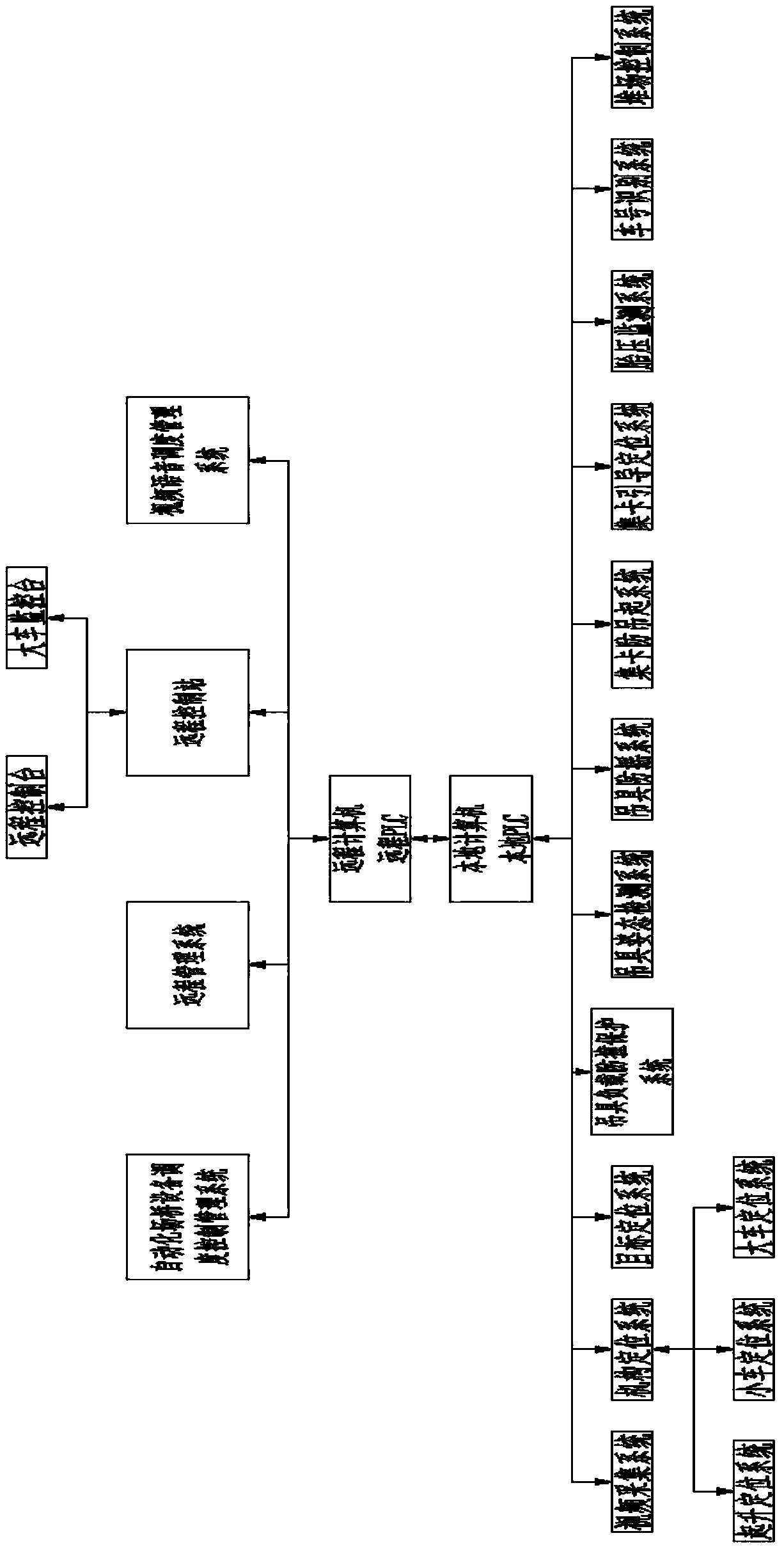

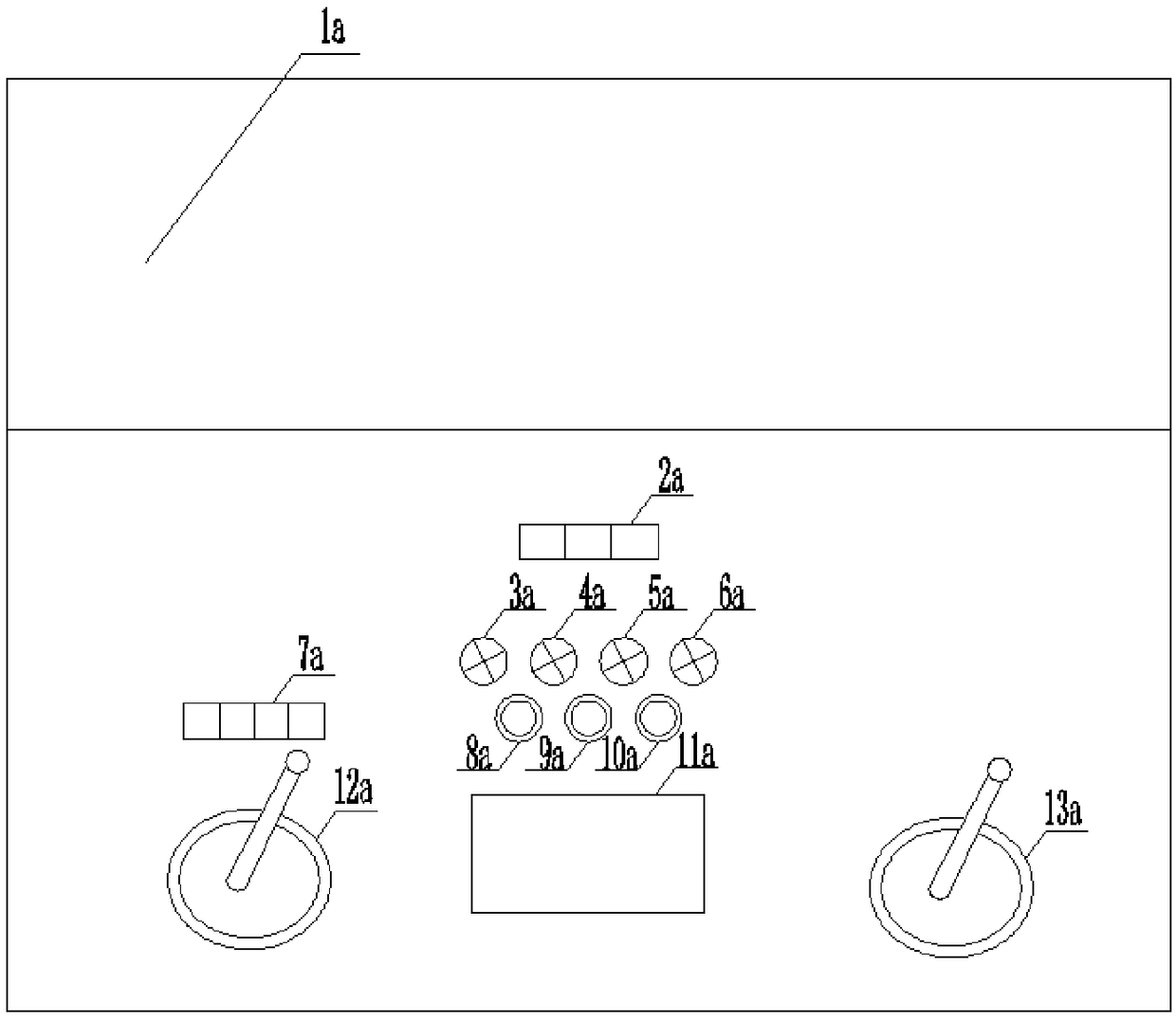

[0031]See the accompanying drawings for details. This embodiment provides a remote control operating system for yard and bridge loading and unloading operations, including a production operation system, a remote automatic control system, a cart motor, a trolley motor, a trolley encoder, a spreader angle lock and a telescopic mechanism. The present invention adds a remote automatic control system. The remote automatic control system includes an automatic field bridge equipment scheduling control management system, a remote management system, a remote control station, and a video and voice dispatch management system. The remote control station is connected with the automatic field bridge equipment respectively The dispatching control management system, the remote management system, the remote control station, and the video and voice dispatchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com